In apartment buildings, especially old buildings, the kitchen has one electric cable. It is designed to connect an electric stove. But modern equipment is evolving, and the conventional stove has been replaced by a more developed and powerful technique that requires a greater load. Dependent and independent ovens and hobs are very popular. In this case, you need to connect the hob and oven to one outlet. The connection must be carried out taking into account all the nuances and subject to safety precautions.

Plate options and outlet selection

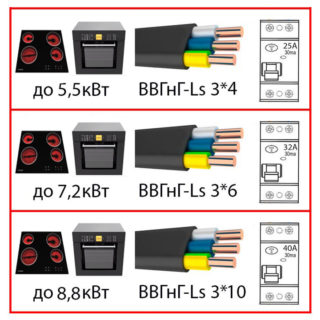

Modern ovens and hobs are classified as powerful household appliances. For operation, they require power from up to 10 kW. To connect such a technique, you need to select the correct outlet and cable of suitable cross section. Household appliances up to 3.5 kW are equipped with their own 16 A socket and are designed for 220 V.

For the hob, you must independently select the entire kit for connecting to the mains. Powerful devices with a load of 3.6 kW to 7 kW must be connected through a 32 A power outlet.

Power sockets are overhead and internal. Overhead products are used when laying electrical wiring in an open way. Typically, such models are installed in wooden houses and rooms with a high level of humidity due to their protection from dust and water. Internal sockets are mounted in the wall itself and are used in panel and brick buildings.

According to the purpose and design features of the outlet are:

- for single-phase 220V networks;

- for three-phase networks 380V;

- having a separate contact for grounding or without it;

- with fixation, push-button or threaded, with a union nut;

- with integrated devices - RCD, trip relay, timer;

- with curtains covering the outlet of the outlet.

The main criteria for choosing oven outlets:

- Current strength. You need to know in advance the maximum load from household appliances that will be connected to the power point. Based on this value, an electrical outlet is selected.

- Phase - 220 V or 380 V. In apartments single-phase networks, in country houses - three-phase.

- Degree of protection against moisture and dust. It is recorded as IPxx, where the first digit is the level of protection against dust, the second is protection against moisture. The kitchen is a room with a high level of humidity, for it the minimum figure is IP24.

The apartment has wiring with its own parameters, made of a certain material. These data will be required for further connection of household appliances.

In houses built before 2001, aluminum wiring was used. New homes or buildings that have undergone a major overhaul with electrical wiring replaced are equipped with safer and more stable copper wires.

The cable cross section is selected taking into account the load. You can find it out by special tables, which show the dependence of the diameter of the wire on the connected load. The calculation is based on the PUE 7. For example, for a copper cable with a cross section of 6 square meters. mm maximum power should not exceed 7.4 kW for hidden wiring and 11 kW for open wiring. For an aluminum wire of the same cross section, these values will be 5.7 kW for hidden and 8.5 for open wiring. On a copper cable with a cross-section of 4 sq. Mm, it is possible to supply a maximum power of up to 5.9 kW with hidden wiring and up to 9 kW with open. A similar aluminum cable can withstand 4.6 kW and 7 kW, respectively.

The cable must be double insulated, made of non-combustible and waterproof material. It is recommended to take wires of the VVG brand with three or five wires (depending on the number of phases).

Selection of remedies

Powerful household appliances must have protective equipment installed. These include circuit breakers and RCDs. A 32 A circuit breaker is needed for an oven and hob with a power of up to 5.9 kW. The machine current is similarly selected according to the table taking into account the total load.

When choosing a machine, you need to take the closest value, which is slightly higher than the calculated current. It is impossible to overestimate values. In this case, the risk of skipping excess load increases, which can lead to the failure of equipment or fire.

What is the difference between an independent oven and a dependent

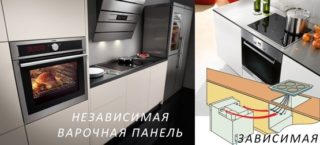

Ovens can be divided into 2 groups - dependent and independent. They differ in design and method of connection to electricity.

Ovens can be divided into 2 groups - dependent and independent. They differ in design and method of connection to electricity.

Dependent models are installed in niches of specially designed furniture. The oven and hob are stacked on top of each other. They have a single system for connecting to electricity and a common control method. You cannot use them separately from each other. Such devices are widely represented in the household appliance market.

Independent devices are gradually replacing dependent ones. They are distinguished by convenience, ease of installation and use. The oven and hob are not connected to each other, they can be controlled separately. They do not have common wires, which facilitates the connection process. The way to control each device can be different - touch, keyboard, remote.

Equipment connection

Algorithm for connecting the hob and oven to one outlet:

- Selection of necessary materials (power sockets, cables, professional tools).

- Choosing the optimal connection scheme.

- Installation in a switchboard of a separate circuit breaker for a plate and laying of a separate cable from it.

- Installing an outlet and attaching a plug with a cable.

To install the hob, you will need the following tools:

- drill;

- electric jigsaw;

- knife;

- screwdrivers;

- ruler;

- pencil;

- square;

- cardboard.

Installation is carried out in 3 stages:

- Plate size measurement. According to the measured data, you need to create a template on cardboard, which is then transferred to the surface of the cabinet.

- The marked part must be cut to install the slab. This is done using a jigsaw along the intended contour.

- The final stage is the installation and fastening of the plate. A hob is placed in the hole made. Joints should be sealed with sealant.

According to current SNiP requirements, the plate can only be connected via a separate power cable. It is forbidden to install sockets and other points of electricity consumption on it.

In apartments, the connection scheme provides only a single-phase connection to 220 V. In cottages and private country houses there are three-phase electrical networks of 380 V. This must be taken into account when connecting.

In apartments, the connection scheme provides only a single-phase connection to 220 V. In cottages and private country houses there are three-phase electrical networks of 380 V. This must be taken into account when connecting.

To evenly distribute the load on the network, you can implement a circuit with two phases, zero and ground. When connecting, it is important not to mix the cores. On counters, automatic machines and other devices, alphanumeric marking is done. The letters 1L, 2L, 3L are the phases, N is zero. Earth is indicated by the corresponding icon or letters PE. The cores are usually marked with flowers. The yellow-green wire always indicates the earth (yellow with a green stripe). Blue or blue mark zero. The phase can be painted in any other color.

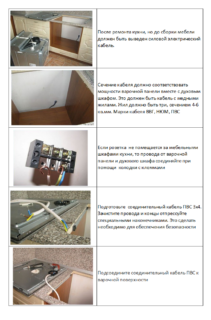

The panel must be connected to the cable through a special box of terminal blocks or through an electrical outlet. The first method is often used by professional electricians. It is reliable, but inconvenient in operation.If you need to dismantle the panel, you will have to disconnect the wires in the terminal box, and then reconnect them. Using a plug and socket will simplify the procedure.

The cable can be connected to the plug and socket in several ways. The first method - the core is cleaned from the insulation coating by 5 mm and fixed with a screw. The second method is safer and more sustainable. The connected conductor is cleaned from the protective layer by about 1.5 cm, folds in the form of a ring around the fixing screws and is clamped. Safety is achieved by increasing the area of contact.

A wire may consist of many thin veins. They are easily destroyed during operation, so it is recommended to treat them with a soldering iron.

The terminal block or socket must be installed next to the stove. The installation location should be accessible so that the user can reach it if necessary.