LED strip is a modern type of lighting equipment. It is used in the interior decoration of rooms and for the exterior decoration of building facades. Proper installation and fastening is a necessary condition for its reliable operation.

Surface preparation

LED strip is used to create lighting in the living room, bedroom, bathroom, hallway, kitchen. Due to its flexibility and adhesive base, it is attached to wooden, plasterboard, metal, plastic, ceramic surfaces. Their shape can be rectilinear, curved, spherical.

During installation, the following rules should be followed:

- No mechanical impact on the board should be allowed.

- You can cut the tape in specially marked places.

- When the LEDs work, heat is generated, so the canvas should be cooled.

- Connectors are used to connect sections of the LED strip.

- The tape is connected to the network through a power supply unit of appropriate power, which provides a voltage of 12 or 24 V.

The adhesive base of the LED strip is 3M acrylic tape. For its strong adhesion to the surface, the following conditions must be met:

- The surface should be flat, without protrusions, sharp edges, knolls.

- The base is pre-prepared: cleaned, dust removed, degreased with isopropyl alcohol or a cloth with an adhesion promoter. White spirit or acetone can be used to degrease metal and plastic substrates. Painted surfaces are treated with a solution of vinegar.

- Marking is applied on the base, which allows to fix the canvas along the necessary path.

- The room temperature is above 18 degrees. At room temperature, the adhesive tape seizes as much as possible during the day. At temperatures above 60 degrees - within an hour.

LED strip can be glued to wood. The wooden base must be smooth, painted or varnished. It does not hold on an unprepared surface and quickly peels off.

Gluing materials

The LED strip has a standard self-adhesive base. But for long-term fixation on rough surfaces, for example, wooden, it is unsuitable. The list of materials that can be used for gluing LED strip is as follows: aluminum profile, adhesive tape for led strip, aluminum adhesive tape, quick-setting adhesive. They improve properties and increase fastening efficiency.

Adhesive tape for LED strip

Commercially available tapes are a printed circuit board with LEDs, mounted on double-sided tape. Its free side used for installation is protected by a smooth transport film. For high-quality models, it is marked 3M.

How to stick the LED strip:

- On a previously prepared surface, marking is applied.

- Solder the contacts of the backlight or use a connector to connect the wires, the power supply; install a switch.

- Using a sharp object, the beginning of the tape is separated from the protective film, a section of 15-20 cm long is released.

- Apply a strip of LEDs to the surface and press firmly.

- Gradually freeing sections of adhesive tape from the film, completely glue the tape along the marked path. When making connections in the corners, they do not bend it, but use corner connectors or solder it.

- Install the power supply in a convenient place protected from moisture.

If, when removing the protective film, conductive tracks are exposed, it is necessary to apply a substrate of electrical tape to this place. Otherwise, a short circuit will occur during connection.

You should accurately apply the tape to the markup. If it is improperly positioned after disconnecting, the adhesive tape loses its properties. Firmly attaching it again will be problematic.

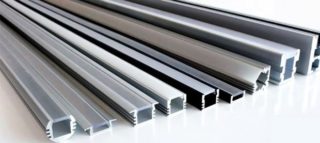

Aluminum profile

The optimal mount for LED backlighting is aluminum profiles. They are used for extended powerful models SMD 2835 and SMD 5630, 5730 and for the popular SMD 5050 based on LEDs. For fastening structures with a power of more than 14 W, their use is mandatory.

Profiles are overhead, mortise, corner. The LED backlight is glued inside the profile, and it is mounted on the selected surface.

Properties of the aluminum profile:

- self-adhesive tape surface ideally adjoins to the even and smooth basis;

- easily and firmly attached to the mounting plane;

- through the aluminum surface the heat generated during the operation of the LEDs is removed;

- The matte diffuser, which closes the front of the profile, gives a pleasant appearance and makes the lighting softer.

An inexpensive alternative to the aluminum profile is a plastic cable duct without a cover. Its drawback, which leads to a premature loss of brightness of the LEDs, is poor heat dissipation during operation. Therefore, its use is not justified.

Glue

The right adhesive for the LED strip provides a quick setting. Adhesives cope with this task:

- based on cyanoacrylate, called superglue, for example, “Super Moment”;

- based on rubber or silicone, for example, liquid nails "Titan" or "Installation moment".

Adhesive fixing recommendations:

- Superglue is applied pointwise through 50 - 100 mm. So the tape is firmly fixed and, if necessary, it is easier to dismantle than when applying the adhesive in a continuous layer.

- A strip with LEDs is applied with the base to the surface on which the adhesive is applied, and confidently pressed.

Adhesive bonding is used on vertical, inclined porous surfaces. It is resistant to temperature and humidity. The tape is grasped to the correctly processed surface in 20-60 seconds. They completely stick together in no more than 2 hours. With glue, you can attach the LED strip to metal, wood, plastic, wallpaper, glass.

Hot melt is not recommended. It attaches well, but due to low heat-removing properties, overheating of the emitting crystals and their premature failure can occur. Under the influence of elevated temperatures, it melts and gives off an unpleasant odor.

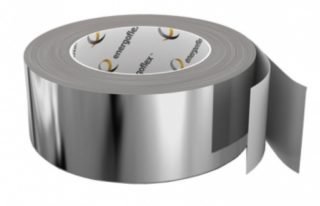

Aluminum tape

If it is not possible to use the profile of the led strip of low and medium power (6-10 W), they are mounted on aluminum or foil tape. Its surface has heat-removing properties and can serve as a reflector.

Aluminum tape for LED strip is glued to the surface according to a pre-applied marking. To ensure a good connection, superglue is spotted on it. Then a strip with LEDs is attached to the tape.

Other mounts

If the led strip is hidden or the appearance does not matter, you can use for fixing:

- disposable nylon ties;

- plastic clamps.

Do not fasten the LED strip with staples using a construction stapler.

Spread the two ways to stick the LED strip: tape and glue. Adhesive tape peels off over time. The strength of this installation is increased when using superglue. Optionally mount the backlight with an aluminum profile.

Sticker Tape 220V

Models rated for 220 V are available without an adhesive backing and placed in a sealed enclosure. They heat up during operation, so they are not recommended for use indoors. Used to organize outdoor lighting of buildings in well-ventilated areas.

You can attach such a model in one of three ways:

- mounting on an aluminum profile with clamps;

- fixation with the help of mounting pads, clips, studs;

- gluing on double-sided tape.

For fastening on adhesive tape, it is cut into strips 3-5 cm long. On one side they are glued to the canvas after 5-7 cm. Then the structure, separating the free surface of the adhesive tape from the protective film, is fixed in the required place.

When applying 220V LED strip on the street, the most reliable option is clip fastening.

Rough Surface Sticker Rules

The flexibility of the LED board allows you to stick it on the surface of any geometric shape, including arches and circles.

When sticking the tape, such surfaces must be cleaned of moisture, dust, grease and other contaminants. Additional strength of fixation is provided by applying glue. Rough surfaces, such as wood, are pre-painted or varnished to give smoothness and increase the contact area.

Where to hide the LED strip

Depending on the type and shape of the base on which the tape with LEDs is mounted, it can be hidden in several ways.

- Ceiling. LEDs are mounted in a ceiling plinth or drywall cornice. To prevent the tape from being visible, lay it to a depth of at least 2 cm. If stretch ceilings are installed, first attach the backlight and lay the wires, and then stretch the canvas.

- Walls. To hide the tape in the wall, make a niche in the form of a box of drywall. Low-power models are mounted directly on the surface of the niche; for powerful models, an aluminum profile should be used.

- Furniture. LED lighting can be attached to any cabinet furniture in the living room or bedroom, kitchen. It is glued to the base of the hanging cabinets, inside sideboards or slides with glass doors, highlighting their contents. To organize decorative lighting, it is glued to the top of the furniture.

- The stairs. You can emphasize the stairs in a multi-storey building using LED lights. It is laid under the steps or in the recesses in the railing.

The hidden tape complements the main lighting with diffused light, creates illumination in the dark, focuses on decor elements or is used for zoning the space.

Common Errors and How to Fix Them

The life of the LED strip will increase if you do not allow such errors:

- Sticking backlight on the surface of ceilings, walls, furniture without a profile. This mount does not provide cooling tape, overheating, it will quickly detach, the LEDs will fail.

- Bonding of bare LED tracks. Mounting the tape on a damaged base through which the LED board comes through will cause a short circuit when connected. To avoid this, apply an insulation layer to damaged areas.

- Using a stapler for mounting on wooden and plasterboard surfaces. To attach the backlight, you need to shoot brackets many times. If you allow only one inaccuracy, the LED board will be damaged and the tape will be unusable.

- Mounting on a plastic profile from the cable channel. This type of profile is not intended for mounting LEDs: it does not provide heat dissipation, which leads to overheating of the structure.

- The use of hot glue. When the LEDs work, it will heat up, preventing the removal of heat, and emit a harmful smell.

The LED strip should only be glued using specially designed materials.

What to do if the LED strip has come unstuck

Depending on the length of the peeled off area, you can apply one of the following methods:

- If the length of the section of sagging is small, without violating the overall design, it is fixed with superglue.

- If a substantial segment of the tape is detached, the entire structure must be re-glued. To do this, it is better to use a durable adhesive tape brand 3M.

The tape is re-glued in the following sequence:

- carefully dismantle the LED backlight;

- the base is cleaned of the remnants of the old glue;

- a new double-sided tape is glued to the surface of the cleaned area;

- release the adhesive tape from the protective film and fasten the tape in place.

With the correct procedure and using high-quality adhesive tape, a stable and durable fastening of the LED strip is provided.

Installation of LED strip does not require special skills. It is easily mounted on its own scotch tape base. The use of additional techniques and inexpensive materials will ensure high reliability of fixation. Effectively glue the backlight using an aluminum profile, using tape and superglue together.