LED lighting is considered the most energy efficient. However, there is a significant drawback - LEDs require special power. You can’t just take and connect an LED strip or lamp to an ordinary 220 V power outlet. For productive and uninterrupted operation, the installation of special power supplies is required.

How to choose a power supply for LED lamps

To select a suitable model, it is necessary to correctly calculate its power, equipment with a cooling system. The role is also played by the type of execution and functionality.

The main task of the cooling system is to reduce the temperature of the source, extending its operational life. This design is divided into several types, it can be active and passive. The first system is equipped with a fan, has a compact size, but is noisier compared to the second and requires regular cleaning. The passive design takes up more space, but it works almost silently and is easy to use.

The power supply units of the LED lamp according to their functionality are divided into the following types:

- Conventional PSUs. Their main task is to ensure the smooth operation of the tape.

- PSUs equipped with an integrated control device, which is called a dimmer. Its task is to provide work and control the brightness and colors of LED lamps.

- With remote control. Included is a remote control that works via infrared or radio.

- Modifications with the maximum configuration. A remote control and dimmer are included with the LED lamp. This design avoids the installation of additional equipment in different places.

Next, you need to decide which type of power supply for the LED strip in execution will be preferable. Structures are fully open, semi-hermetic and completely sealed. When choosing, you need to analyze in which room the lamp will work - the production area, living room or bathroom. The maximum degree of protection is required if the lighting fixture is designed for outdoor use.

The simplest, budget and most common design is open models placed in a case made of high-quality plastic. This type is only partially protected from dust, suitable for use exclusively in dry rooms. In a machine, for example, sources are used to illuminate the dashboard of a ceiling or floor. When installed in a living room, it is worth paying attention to a relatively small power (up to 75 watts). For normal lighting, at least 2-3 tapes will be required. They are usually masked behind a suspended or suspended ceiling.

A characteristic feature of the semi-hermetic power supply is its relatively affordable cost and average size. They are intended for installation in rooms with high humidity, but with a small likelihood of water getting directly onto the case. For example, in the bathroom or in the kitchen they are mounted under ceilings or special canopies. They can also be operated at industrial facilities.

Sealed structures are blocks placed in protective capsules, they protect the mechanism from the harmful effects of the environment. The control board is filled with silicone, located inside a transparent glass. Such a variety is used, as a rule, to create external lighting for the machine, as well as to work in conditions of high levels of dust and humidity.

In comparison with analogues, the size and weight of sealed modifications is larger. Increased power up to 100 watts, which allows you to power long tapes.

Control unit specifications

The power supply is an electrical design whose main task is to convert the current strength of 220V to 12V or 24V, depending on the required value of the operating voltage. In most cases, switching power supplies are used to power LED lamps. Resistors act as limiters here. There is a common analogue of the power supply - the driver, its drawback is the lack of current limiters.

When choosing a power supply for LED bulbs, you need to familiarize yourself with the characteristic features that the device should have.

- The operating voltage of the lighting device.

- The total power of the LED strip.

- The need to protect the PSU case from the harmful effects of the environment.

- Overall dimensions of the structure.

Working voltage

The working voltage of LED lamps, depending on the modification of the design, is 12V, 24V and sometimes 36V. The operating voltage of the controlled SPI LED strips is only 5V. For smooth operation, the output voltage of the power supply must comply with the specified parameters.

There are power supplies that allow you to manually adjust the strength of the output voltage, they are used to implement non-standard projects, and also when you need to compensate for the voltage drop on long wires.

There are also non-standard PSU modifications equipped with several channels. Each has a different output voltage. This can be very handy if you feed different tapes to the same source.

Lighting Power

It is necessary to select a power supply by power as follows: power = total power of LED lamps * short-circuit safety factor (it is 15-30%). If you neglect the safety factor when choosing, the electric device will work at the limit, its service life will be very limited.

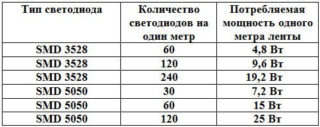

To calculate the total power of the LED strip, each meter of its length is required to be multiplied by the power.

Dimensions

The dimensions of the case are of great importance. Powerful PSUs can be dimensional, it will be almost impossible to hide them, moreover, most of them are equipped with a built-in fan. If you need to connect a long section of tape, you can revise the connection diagram and use the option of operating several smaller and larger units.

When choosing a place for installation, you need to take into account: the higher the power of the device, the more it heats up, so it is important to provide enough space for heat removal, otherwise it will overheat and quickly fail.

PFC in transformer characteristic

Sometimes on the PSU case you can see the PFC marking, which in English means reactive power correction. This parameter indicates on which circuitry the given model is designed, which allows reducing power consumption.

Such modifications are characterized by a high value of power factor; they relate to high quality models with low inrush current. Another advantage of such models is that with a large number of simultaneously used PSUs, there is no need to install and operate special starting machines.

The power supply unit is an electrotechnical design that can not be avoided when installing LED lamps at home, at work, in the garage, etc.