During the construction of monolithic concrete structures, several technologies are used that are required to create optimal temperature conditions. This can be the use of special wires for heating or automatic heaters, as well as greenhouses. The first option is most in demand, since in comparison with analogs it is less energy-intensive and financially expensive.

Why do I need concrete heating

Electrical heating of concrete is required in the cold season, when the ambient temperature drops below the freezing temperature of water, which entails the hydration of the concrete solution. The mixture does not harden as required, but partially freezes.

With the advent of heat, an active thawing process begins, as a result, the solidity of the structure is violated, which negatively affects the durability and resistance to moisture penetration in the cavity of monolithic blocks.

To prevent undesirable and dangerous consequences for human health and life, it is imperative that concrete be heated in winter with special wires. Calculation of footage and laying schemes is carried out at the stage of building design.

The principle of operation and types of heating wires

The most common heating wire type PNSV. This is due to the ease of installation and reasonable price in comparison with analogues.

Still often use an analog of PNSP. Its main structural difference lies in the insulating material. Composition - polypropylene, due to which it is possible to increase the maximum heat output.

The table shows the main technical and physical characteristics of wires of the PNSP and PNSV type.

| Wire mark | Estimated weight of 1,000 meters of wire, kg | The optimal length of the heating section at a voltage of 220 V, m | Nominal Outer Diameter mm | Nominal value of electrical resistance 1 meter of heating core, Ohm |

| PNSV | 19 | 110 | 2,8 | 0,12 |

| PNSV | 18,5 | 95 | 2,7 | 0,18 |

| PNSV | 18 | 80 | 2,6 | 0,22 |

| PNSP | 16,4 | 130 | 2,8 | 0,11 |

| PNSP | 12,7 | 100 | 2,6 | 0,12 |

| PNSP | 14,5 | 110 | 2,7 | 0,14 |

| PNSP | 11,1 | 85 | 2,5 | 0,18 |

| PNSP | 9,6 | 75 | 2,4 | 0,22 |

Heating wires of the type PNSP and PNSV are also used to organize underfloor heating in residential premises.

The main difficulty that builders encounter when using heating wires is the need to calculate the required length. Minor errors are corrected by regulating the voltage supplied to the heating transformer.

Varieties and features of cables KDBS and BET

Despite the wide distribution, the described types of thermal cables have a significant drawback - the need to use special expensive equipment that regulates the power of heat generation by voltage change.

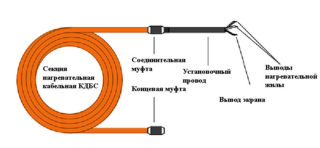

The solution to the problem is the use of two-core sectional self-regulating thermal cables. The domestic modification was called KDBS, and the European - BET (manufacturer - Finland). For their full and uninterrupted functioning, additional equipment is not required; they are connected directly to a 220 V network.

There are practically no differences in the design of the domestic and European models. The table shows a comparative analysis.

| Technical features | KBS | BET |

| Degree of protection | IP67 | IP67 |

| Section Size, m | 10 to 150 | 3.3 to 85 |

| Nominal diameter mm | 7 | 6 |

| Recommended Bending Radius | 35 | 25 |

| Resistance of insulating material, Mom / m | 103 | 103 |

| Linear Power, W / m | 40 | Depending on the model and length, it ranges from 35-45 |

| Operating voltage, volt | 220-240 | 220-230 |

Domestic models have their own marking features. They are encoded in the following form: ХХКДБС YY, where ХХ are the linear power indicators, and YY is the section length.

Electric heating of concrete with PNSV wire

After carrying out and approval of all calculations and schemes, they begin to warm up. The technology is as follows:

- The heating element is evenly laid out at the place of filling. It is important that the cable parts do not touch each other. The heating object must not go beyond the boundaries of the structure and interact with the formwork.

- Before removing the ends of the cable beyond the boundaries of the heating, the cold ends are securely connected to the heating outputs by soldering. For maximum protection, the soldering spots are additionally wrapped with metal foil.

- A test check is carried out using a megaohmmeter and a measured phase load of the current is measured.

- If the system is workable and there are no complaints in the implementation of the project, the structure is poured with concrete mortar.

- A current is supplied through a step-down transformer substation.

This is the easiest way, allowing you to effectively warm concrete with a wire without disturbing the operating characteristics.

Wire installation

The wire is laid inside the formwork even before the cavity is filled with concrete. As a rule, it is fixed with a soft aluminum wire to the fittings, but according to the safety rules, this approach is not welcome. The minimum radius of curvature is at least 25 cm, due to the high stiffness of the steel core. This rule is especially true when lowering the ambient temperature, despite the fact that vinyl insulation retains its physical properties at temperatures up to -30 degrees. At -10 degrees, sharp bending can cause a violation of the integrity of the insulating layer.

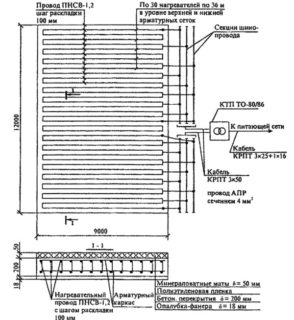

For uniform heating, the wires are laid parallel to each other with an interval of not more than 15 cm. For 5 cubic meters. Concrete requires about 30 m of cable type PNSV 1.2.

With a voltage of 220V, about 17 meters of cable is required, and at 380V a minimum of 31 meters. With this approach, the entire system will warm up evenly. If a longer section is laid, heat will be released no further than 5-6 meters from the point of connection to the mains.

The cable is connected to the supply network outside the borders of the formwork. As a rule, this is carried out using aluminum conductors, with which the ends of the PNSV are tightly wrapped in several turns.

Advantages and disadvantages

In this way, warming up monolithic concrete structures is beneficial due to the economical energy consumption and low cost of cables. Of particular note is the resistance of the wire to chemical attack (acid and alkaline), which allows them to be used when different additives are added to the building mixture.

Despite the significant advantages, there are also disadvantages:

- the need to use special equipment - PT;

- difficulty in calculating the required cable length.

The cost of special equipment - lowering stations - is high. The use process is short-lived, and the cost of rent, as a rule, is about 10% of the unit cost. The use of welding machines is possible when heating small structures.

Installation of a sectional heating cable

When installing a sectional heating cable, there is no issue with trimming, since the heaters are sold in finished sections, and not in bays. For winter concreting, it is required to calculate the power of the heating element based on the concrete cubes used in a monolithic concrete structure.

The technology of TMW concrete is accompanied by an instruction, which states that for heating 1 cubic meter.building mixture will require from 500 to 1500 watts. It all depends on the weather on the street. If you use a few simple techniques, you can significantly reduce the cost of paying for electricity:

- pre-heat the formwork;

- use special nozzles for the mixture, which allow to lower the freezing point of the solution.

If you have to fill the floors or beams, the calculation of the required material is carried out from 4 linear meters per square meter of surface. If you have to build three-dimensional structures, for example, I-beam concrete beams, the electrical heating is stacked in tiers with an interval of not more than 0.4 meters. Protection of heating wires allows them to be securely wrapped to fittings.

The interval between the electric heater and the surfaces of the structure must be at least 20 cm. For uniform heating, the distance between the cables must be the same.

Advantages and disadvantages of segmented cable

Segmented wires have undeniable advantages compared to their peers:

- simple calculation of the length of the required heating element, ease of installation;

- the probability of electric shock is minimal;

- for the organization of heating of building material does not require additional use of expensive equipment.

The disadvantages include a relatively high cost.

Post Processing Concrete

Soon after warming up concrete monolithic structures, it is impossible to start processing them. Pre-building material should harden and achieve optimal performance of brand strength.

Shock loads are also contraindicated. Cutting allowed. For this, equipment equipped with diamond nozzles is used, after which no cracks form. In general, heating concrete with heating wires resembles the operation and arrangement of underfloor heating.

The use of nichrome cables for heating concrete mix is prohibited by safety regulations. In addition, this approach will cost the customer large financial costs.