In any electrical line, even at the design stage, it is possible to completely turn off the current. This is necessary to conduct a survey of communications, perform repairs and routine maintenance, replace or install new equipment. The circuit breaker is the most reliable and efficient device, with the help of which the circuit is broken with the guaranteed prevention of breakdown in the off state.

What is a switch

Products of different designs can be found in the entrances and basements of houses, on the street and in public buildings. In most cases, all types of circuit breakers are located in switchboards in whole or in part.

According to the classification, the electric switch is a part of the distribution mechanism and is designed to open the circuit in manual mode. The product is designed to operate in the range of 100-1000 amperes with a maximum voltage of 1000 volts. The current is interrupted by muscular effort by creating a line break.

The cross over switch breaker can be made in open and closed execution. The design depends on the magnitude of the load that is applied to the contacts. This is justified by the fact that the rotary switch at the stage of activation and deactivation creates an arc and a sheaf of sparks that can cause injury to a person and cause a fire.

Products operate on direct and alternating voltage, can be used for switching single-phase and three-phase currents.

380 V circuit breakers are used in production and in homes where consumers operating from such a voltage are installed. In private homes and cottages, the use of switching two-phase devices for 220 V. is practiced.

Switch device

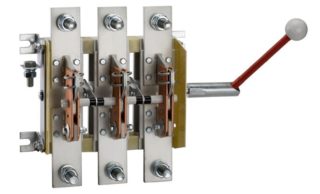

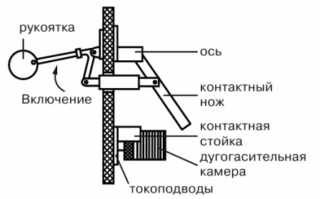

The knife switch is a simple, but well-designed device, due to which it is widely used in electrical work.

Switch device:

- Base. It is intended for reliable fastening of units and mechanisms of the device.

- Fixed contacts rigidly fixed to the base and having terminals for connecting cable wires. They are double plates with elasticity.

- Fixed bracket for mounting the movable element. Made of durable abrasion resistant material.

- Movable contact made in the form of a knife or fork for a consumable insert.

- Handle equipped with an insulating pad at the gripping end.

Depending on the number of directions and poles, the electric three-phase switch has 3 output and 3/6 input contact pins. The design of the device is designed for strong contact retention regardless of their mass and vibration level. All parts through which current is passed are made of a special M1 copper alloy. Corrosion protection is carried out by applying tin to them.

The difference between the switch and the disconnector

The difference between the circuit breaker and the disconnector is in the mechanism of disconnecting the line, the distance between the separated ends and the presence of an electric arc.

The 380 V switch is used to disconnect devices under load - in the on state. The device makes it possible to carry out any manipulations with electrical equipment without disconnecting the entire residential object. In this case, the distance between the contacts is sufficient so that no breakdown occurs. The body of the device closes the contacts, which prevents the ion arc from entering adjacent parts or the ground line.

The purpose of the knife switch is to de-energize the entire object. The load is previously disconnected to prevent melting of the contacts. The emergency disconnection of the line is allowed in case of emergency - fire, breakthrough of the water supply or heating system.

Advantages and disadvantages

Reversing switch-disconnectors are in demand in all sectors of economic activity.

The popularity of products is based on the following advantages:

- Durability and reliability. The devices are resistant to mechanical stress and vibration.

- Long term of operation. High wear resistance of contacts and swivel joints ensures the durability of devices even with frequent use. The resource of the device is 3000-5000 shutdowns.

- Safety. There is no risk of electric shock, explosion or fire.

- Minimum maintenance costs. Enough periodic lubrication of the joint.

- Wide temperature range of operation.

- Ecological cleanliness. Devices do not emit harmful substances into the environment.

- Compactness. Small sizes make it possible to install several products in one shield.

- Affordable cost.

- Simplicity and speed of installation.

Among the disadvantages of the circuit breakers is a high level of switching overvoltage that occurs between the contacts at the time of the minimum distance between them. This requires the use of effective measures to protect switching points.

Application of a knife switch

Product scope:

- transformer booths;

- local step-down substations;

- introductory guards in the entrances of houses;

- industrial equipment in workshops;

- warehouses;

- public places;

- offices, offices and other institutions;

- catering establishments;

- private houses, summer residences, cottages.

Before installation, a schematic drawing is made, on which the line, consumers and switches are indicated. To make a drawing, you can use a computer program. A single-phase or three-phase switch is located in the shield, which excludes access to it by unauthorized persons.

The main types

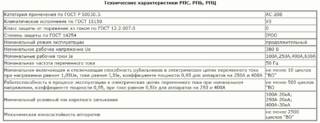

By marking the switch in the shield, you can find out its type, device and potential capabilities.

The following decryption is installed:

- P - circuit breaker;

- P - switch;

- P - front connection of wires;

- B - side handle;

- C - the central lever;

- digits - the first (1-3) number of poles, (4-6) current strength (1 - 100 A, 2 - 250 A, 4 - 400 A and 6 - 600 A).

Different types of circuit breakers are classified in the following areas:

Different types of circuit breakers are classified in the following areas:

- Current strength (100-1000 A).

- Number of poles (1-3).

- Type of current (constant, variable).

- Control method (side, center).

- The method of connecting the wires (front, rear).

- Direction of current (1-3).

- The presence of a fuse in the knife.

- The presence of an arc extinguishing system.

- Installation of auxiliary contacts.

- Degree of protection (open and closed execution).

- Temperature operation (hot, cold, moderate).

When choosing a product, it should be borne in mind that only de-energized circuits can be disconnected with devices with a front handle. For lines under load, devices with a side handle are used.

How to do it yourself

The cross over type product is often installed in buildings that are often disconnected from electricity. In such cases, a gasoline generator is used, which provides the object with energy. For quick and safe switching of current from the network to the generator and vice versa, a switch is installed, which has 3 positions (0 and 2 lines).

To collect it yourself you will need:

- drill;

- hacksaw;

- pliers;

- spanners;

- roulette;

- plastic pipe.

- copper tube;

- bolts and nuts.

Description of the manufacturing sequence of the lever type switch:

- Bonding the case from the boards.

- The contacts from a copper tube, which is cut into pieces, are flattened and bent.

- Drilling holes in the contacts, making rivets.

- Drilling holes in the housing.

- Making a knife.

- Screwing the bracket and contacts to the base, joining the knife.

- Mounting on the cross over element of a plastic tube.

- Threading in contacts, screwing in clamping bolts.

It remains to bring and secure the wires.