Switchboards are installed in buildings supplied with electricity. The electric box organizes, isolates the distribution and protective equipment: circuit breakers, RCDs, differential machines, voltage limiters, counters, as well as adjacent cables from environmental influences, mechanical damage, extraneous interference in the distribution system.

Types of equipment in accordance with GOST

The guards belong to the low voltage switchgear (low-voltage complete devices), therefore, the general rules for their installation and installation are described in GOST R 51321.1-2007. Equipment requirements for industrial, public and residential buildings are different. GOST 32395-2013 regulates household use, and GOST R 51778-2001 - industrial and public. The panels must correspond to the electrical installations of buildings under construction and already in operation with the grounding systems TN-S, TN-C, TN-C-S.

The GOST 32395-2013 standard applies to multi-unit buildings of mass development and an individual plan, cottages, rural and garden single-family houses. Nominal connection parameters: voltage 230 V or 230/400 V, frequency of three-phase alternating current 50-60 Hz. Access to panel panels is provided by unskilled users to turn on and off the power supply to the internal electrical system, but there are lockable boxes with the possibility of sealing. To protect a person, electrical panels use grounding elements, working or double, reinforced insulation.

Shield Box Design

The box for automatic machines is represented by the product lines of domestic and foreign brands. A simple model can be assembled independently if you have the ability to handle metal. The main structural elements are several.

Housing made of metal or refractory (insulating) plastic.

The metal case is made of sheets of steel with a thickness of 0.5-1.5 mm, coated with powder paint to prevent corrosion and environmental influences. This performance is more expensive. Plastic - from polymers that withstand high temperatures, overheating. More aesthetic if you fit into the interior. There are miniature options for 2-6 modules.

The degree of resistance to electrical, thermal and mechanical influences is determined by the IP ** marking, where the first * is expressed as a number from a number 0-6 and shows the level of protection of a person from contact with electricity and equipment from solid particles and dust, the second * - protection against moisture (0–8).

For outdoor installation, the enclosures of the switchgear must be protected from water by at least 3. For this, sealed models with a rubberized perimeter of the cover are used. The degree of protection of the shell and operational often diverge, so two values are indicated.

Electromagnetic processes affect the quality of plastic and rubber parts - they lose their properties under the influence of thermal loads. The insulating material that touches the conductive parts withstands the test with wire heated to 960 ° C. For other prefabricated elements, 650 ° C is sufficient.

The mounting box for the meter and metering and distribution units has an insulated or uninsulated window through which the readings are visually monitored. Plastic models are released with a transparent cover. Input / output of wiring to / from the housing is through technical holes. After installation, they are closed with special plugs.

Other elements of the electric box:

- Internal damper for insulation of wiring.Required if access to the panel is not only qualified personnel. A widespread screen with a slot for access to the readings of accounting equipment, circuit breakers and switches. If necessary, the partition is equipped with a special lock, sealed so that only employees of the electrical service organization had access to the wires.

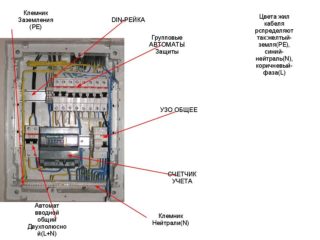

- Mounting plate, rail for modular elements, or a combined version. The classic option for fixing devices is a plate with mounting holes. Most modern boxes are equipped with a 35 mm wide metal profile (din rail) for fixing modular equipment. The shells contain one or more fastening bands, depending on the estimated or actual number of machines inside. 17.5 mm are allotted for one module on the rail, the distance between the centers of two adjacent elements is 18 mm. The difference is due to the need to leave air gaps between pieces of equipment. You need to understand that the size of one module is equal to a single-pole switch. For bipolar - 2 modules, single-phase RCD - 3, three-phase RCD - 5, electric meter - 6–8. Regulatory indentation is waiting for rows of vertical profiles - 125 mm.

- Busbars for zero tap (N), ground (PE), common conductor (PEN). Fastened with screws to the body, some models - on a din rail.

- Self-tapping screws for fixing built-in and hinged drawers.

- Inside the shells sometimes there are partitions and compartments.

- The complete set of expensive models can be supplemented by clients, jumpers, have removable sides of the box.

The size of the boxes is directly related to the wiring diagram. The more lines, protective equipment, the larger the case. For a dashboard without a meter, a box for 12-24 modules is usually sufficient.

Types of GCC

Depending on the location of the case, the boxes can be for outdoor use and for indoor use. Outdoor protection must be at least IP44. Metal hermetic anti-vandal boxes with 2 doors are common: the inside has a mail lock, and the outside has a complex screw. The thickness of the steel is 1.5 mm. Shells made of shockproof plastic are found. The external box for the electric meter is characteristic of private houses.

Depending on the location of the case, the boxes can be for outdoor use and for indoor use. Outdoor protection must be at least IP44. Metal hermetic anti-vandal boxes with 2 doors are common: the inside has a mail lock, and the outside has a complex screw. The thickness of the steel is 1.5 mm. Shells made of shockproof plastic are found. The external box for the electric meter is characteristic of private houses.

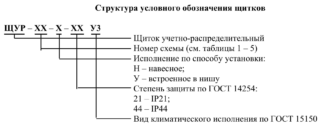

To choose a model is climatic modification: U1, UZ, UHL3, UHL4. Explanation of markings:

- U - temperate climate;

- UHL - temperate and cold climate;

- 1 - street

- 3 - closed rooms with natural ventilation,

- 4 - spaces with artificial ventilation, full or partial conditioning, laboratories.

Content and location of shields:

- group apartment and group accounting are installed in individual dwellings, organize the connection of group chains, are distinguished by the presence of a counter in the second embodiment;

- floor distribution, accounting and distribution and accounting-distribution and group - are located on the walls of floor corridors and staircases, draw a line along the apartment-group nodes, contain apartment accounting equipment and connecting circuits.

According to the installation method, the electric box is mounted, mounted in a niche or floor cabinet. The mortise box is less knocked out of the situation, but for it you need to ditch the wall, which is not always permissible. With open wiring, this installation method is not relevant. Mounted fasten to a vertical surface using a self-tapping screw. Cupboards are screwed to the floor. Collection of electronic "filling" can be carried out both before and after fixing the case.

- Mounted

- Recessed

- Floor

By the presence of protection against electric shock - I or II class. I - the presence of grounding of non-live parts, II - double or reinforced insulation.

By the number of phases - single or three phase. This affects the size and number of technical holes.

The guards are equipped with a low-current compartment for laying telephone, cable, local area networks, security and fire alarms or video surveillance, as well as an introductory device, a riser (power supply) cutter, and remote control.

Basic rules and order of assembly of the shield

The boxes are usually located next to the front door at a height of 1.5 meters. Before installation, they provide good lighting, disconnect the network on the shield above the level, let the cables: power - from above, diverging - from below. The number of devices, their rated current is registered in the equipment passport. The rated voltage is indicated on the housing. The metal sheath is connected to ground. Zero and ground buses contain loose terminals. Wires and machines are labeled with a group of consumers. A circuit is placed on the case to simplify repairs and upgrades.

The boxes are usually located next to the front door at a height of 1.5 meters. Before installation, they provide good lighting, disconnect the network on the shield above the level, let the cables: power - from above, diverging - from below. The number of devices, their rated current is registered in the equipment passport. The rated voltage is indicated on the housing. The metal sheath is connected to ground. Zero and ground buses contain loose terminals. Wires and machines are labeled with a group of consumers. A circuit is placed on the case to simplify repairs and upgrades.

Installation steps:

- Inlet plugs are removed.

- A door or an outer screen is displayed.

- Mounted rails and grounding buses, neutrals.

- Trying on a box in a equipped place.

- Fixing electrical equipment is easier on the desktop.

- Lastly, the door returns to the place.

Before purchasing and installing the shield, you should carefully design the scheme, determine the environmental conditions and budget.