In places where there is no centralized water supply, water wells are used. But over time, they become unusable due to the accumulation of dirt and debris. To avoid this, a bailer is used to clean the well.

Why do you need a bailer

Wells go far deeper into the earth, so they are regularly clogged with dirt and debris. The frequency of use of the bailer depends on many factors that are determined by the region and time of year: climate, weather conditions, type and quality of soil.

In a dry climate, a well can be gelled no more than once a year. In regions with frequent precipitation and a sharp change in temperature, it is advisable to use it for its intended purpose twice as often.

How the product is arranged

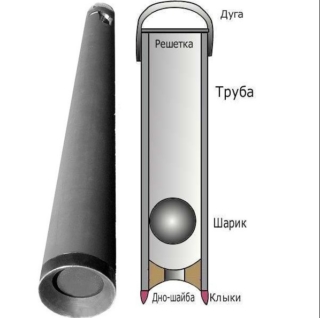

The design of the baffle consists of an all-metal pipe with thick walls, which on one side has an inlet valve - flap and in the form of a metal ball. A cable or rope is attached on the reverse side, with the help of which the bailer is removed from the hole after it is dropped there.

An optional but desirable element in the design is the support to which the cable is attached. It prevents the bailer from falling into the well and staying there. Depending on the complexity of the design, the support may have a whole system of one or more blocks through which the fixing thread is drawn. This principle physically makes it much easier for a person to remove a cleaning device from a well.

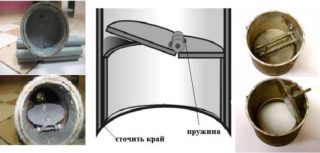

There are two valve options. The first is the metal sphere. It should be heavy, and therefore solid and made of materials with high density. The diameter of the ball should be slightly less than the inner diameter of the pipe, but larger than that of the inlet, otherwise the sphere will fall out of the choke. The second option is a metal plate fixed to the end of the pipe so as to open inward.

Principle of operation

The procedure that must be performed to clean the well:

- The bobbin cable must be pulled through the blocks on the mounting structure in order to be able to conveniently lower and raise it. The length from the block system to the valve at the end of the pipe should be about a meter longer than the depth to the bottom of the well.

- When the preparatory work is completed, you need to direct the pipe into the hole, and then release it, sending it into free fall.

- The flap hits the bottom, and at that moment the valve opens, allowing water with dirt and debris to get inside the flap.

- A second after the impact, the ball or valve returns to its place and tightly closes the inlet, thereby preventing the contents from escaping.

- A man pulls on a cable to raise the bailer and get it to the surface.

- Content is scrubbed out of the pipe through the opposite hole.

The procedure is repeated several times until the owner considers that the well has been cleaned of debris, or its residues can no longer be removed in this way.

Production of a bobbin

The design of the bailer consists of simple components that can be bought in the market or in a hardware store. For its manufacture you will need:

- metal pipe with high strength and density: steel, iron, cast iron;

- sheet metal;

- full metal ball;

- pipe adapter;

- steel cable or strong rope;

- apparatus for welding;

- drill;

- block;

- steel beams.

The key to the effectiveness of the use of a bailer for a well is its mass. The heavier the device, the greater the impact force falls to the bottom, which allows you to capture more garbage at a time. Therefore, the walls of the pipe for the flap should be as thick as possible so that it weighs more.The same applies to the ball, since it acts not only as a valve, but also as a weighting agent. It can be turned on the machine, or use a ready-made ball bearing.

- Inside one side of the pipe, install an adapter with a hole of a smaller diameter than the main part of the structure.

- Weld metal around the perimeter.

- If there is no adapter, you can use sheet metal instead. From the sheet, cut the ring to the size of the outer diameter of the pipe. It is important that the inner radius does not allow the ball to pass through it. Weld the ring.

- At the opposite end of the bumper, drill two holes into the walls one opposite the other.

- Place the steel ball inside.

- Pull the cable through the holes and secure so that it cannot be pulled out. This can also be done with a welding machine.

- Take three steel beams and fasten them together so that a stable, even structure with three supports is obtained. Install it over the well. Then on the resulting mount you need to install the unit.

- Pull the cable.

- Gently lower the choke into the well to check the depth.

It is recommended to stock up with a long cable so that later, if necessary, the excess can be cut off. When the parameters are selected, for reliability, the second end can also be fixed on the supports.

After cleaning the well, the borer should be returned to a condition suitable for operation. Buy a metal brush on a long handle that matches the inside diameter of the pipe. After each use, clean the flap. This is done along the entire length of the progressive movements with scrolling. First you need to remove the ball and wash it in water. It is advisable to place the structure in a container with water for 2-3 hours so that the dirt lags behind the walls.