If it is planned to equip the water supply system in a private house, in the country or to build a bath, it is advisable to understand the characteristics of the water pipes that are suitable for a specific purpose. Each material has its positive and negative sides, which will work well in some conditions and be completely unsuitable in others.

Types and specifications of pipes for water supply

When choosing materials for water supply, buyers mainly focus on the cost, quality and technical characteristics of products. First of all - the characteristics of the material itself - whether it is suitable, for example, for hot water that will come into the pipes from the sauna, or can withstand winter cold to –30 degrees.

The following materials can be found on the market:

- steel - carbon and galvanized;

- cast iron of various modifications;

- polyethylene;

- polypropylene;

- metal plastic;

- copper.

The copper pipe is very expensive. This is a quality material that does not lend itself to corrosion, lasts more than 100 years, and withstands any temperature changes due to its elasticity. But there are also disadvantages:

- installation requires special tools and welding;

- poorly combined with other materials;

- sometimes simply not available for sale due to lack of demand and high cost;

- prone to deformation.

Good performance in operation can be obtained by using cheaper materials, such as plastic.

Plastic pipes

In home construction, PVC products, polypropylene, polyethylene and metal-plastic pipes are used. General advantages are reduced to a long service life - at least 50 years, if they are selected and installed correctly. All materials are easily accessible, easy to install, it is possible to buy fittings of any configuration. For installation, it is not necessary to use heavy construction equipment, since the pipeline is assembled manually due to its light weight.

Polyethylene most often used to supply cold water. For example, from a well to a house. The material is resistant to frost - if the water inside freezes, the pipe does not burst. Products are beneficial to use in cold climates. Well suited for cottages where in winter the heating does not turn on.

Crosslinked Polyethylene - a more durable version of the usual. On the highways you can supply hot water, as well as install pumps that increase the pressure in the system. The increase in pressure does not harm pipes made of cross-linked polyethylene. Sudden changes in temperature also do not have a negative effect.

Polypropylene - the most purchased material. It connects with a low temperature soldering iron, which is cheap. The joints are airtight and durable, so the pipes can be laid on the floor or in the walls and plastered.

There are varieties of polypropylene - reinforced pipes with metal or kapron windingwhich makes them even stronger. In any store there are connecting elements for this material. Of the minuses - with frequent heating, polypropylene can be deformed, which affects only the appearance of the structure. The integrity and tightness of the deformation are not affected. The highway is made non-separable - this must be taken into account. During installation, it is important to withstand all time periods during which the preheating of the pipe ends occurs.

Metal plastic often used in domestic water installations.It is quite strong and durable, but has one significant drawback - after several heating and cooling cycles, the system can leak. This is due to the fact that the joints begin to “hang out”, the fittings do not fit snugly to the pipes.

Plastic is well suited for heating in utility rooms, where the drips are not so scary - sheds, garages, rooms for animals and birds. But for a private house it is better not to apply, so as not to restore the plaster every second year. The material is mounted simply, no need to buy special tools. Rust is not a problem for pipes, since the inner and outer walls are made of plastic, and the middle is most often made of aluminum.

Polyvinyl chloride or pvc stronger than polyethylene. Withstands pressure up to 46 atmospheres. It tolerates high temperatures up to 90 degrees. The material is chemically inert. Especially for PVC structures, you can buy adapters, couplings and angles and do the installation yourself.

Metal pipes

Although most buyers have long switched to plastic plumbing systems, steel and cast iron structures are still for sale. There are buyers for them. They are mainly used for urban communications located underground, where the load on the soil is much higher than on its own site: constant vibrations from moving vehicles, soil shifts. Here we need material that will endure these inconveniences, otherwise repair work with digging the streets is inevitable.

Cast iron It is used to drain aggressive liquids, as it is more stable in chemicals. They are used at car washes, at chemical industry enterprises, where waste of a high degree of pollution goes to the drain.

In a private or apartment building, cast iron is appreciated for its noiselessness and long service life. In this case, the rules for welding or joining products must be observed. Old grades of cast iron have a rough inner surface, which contributes to the adherence of dirt and the rapid clogging of the highway. Newly modified products do not have this drawback. The problem may be the replacement of the cast-iron pipe section with a plastic one, which will require the selection of materials and the method of their connection.

There are two main types of steel on the market - carbon black and silver galvanized. Galvanized steel It withstands temperature extremes and increased pressure in the system. It does not corrode for a long time until part of the protective coating is damaged. Therefore, installation is carried out carefully, trying not to scratch or hit the product.

Carbon steel has a relatively short period of operation - about 25 years. Complicating the situation is the presence of iron oxide in the pumped water. The water supply will have to be periodically disassembled and cleaned, which entails additional costs and the lack of water in the house.

For all metal structures you need to order construction equipment, since the weight of the products does not allow you to mount them manually.

For a home system, metal is rarely used as a water supply material. Most owners of private houses prefer cheaper types of pipes, lightweight constructions that have an increased service life.

Key selection criteria

Depending on the operating conditions, it is necessary to choose materials that will last longer in this situation. For example, to equip a bathhouse, you need to buy pipes that can withstand high temperatures and their difference, because inside the water comes in hot, and outside it gradually cools down.

For the internal water supply, products are selected that have a pleasant appearance, if it is planned to place them in an open way.

If the water supply or sewage system does not have a slope, a pump will be installed that accelerates the movement of effluents, so the pipes must withstand pressure.

Features of installation and connection

Indicate the dimensions of the water pipes in mm and inches. 1 inch = 25 mm. Half an inch - 15 mm, ¾ inch - 20 mm.

To choose the right size, you need a table of diameters of water pipes.

| Inner diameter mm | Outer diameter mm | Wall thickness mm | Weight 1 m pipe kg |

| 6 | 10 | 1,8 – 2,5 | 0,3 |

| 8 | 13 | 2,0 – 2,8 | 0,5 |

| 10 | 17 | 2,0 – 2,8 | 0,7 |

| 15 | 21 | 2,0 – 2,8 | 1,1 |

| 20 | 36 | 2,8 – 3,2 | 1,5 |

| 25 | 33 | 2,8 – 3,2 | 2,1 |

| 32 | 42 | 3,2 – 4,0 | 2,7 |

| 40 | 48 | 3,5 – 4,0 | 3,3 |

| 50 | 60 | 3,5 – 4,5 | 4,2 |

| 65 | 75 | 4,0 – 4,5 | 5,7 |

| 80 | 88 | 4,0 – 4,5 | 7,3 |

| 90 | 101 | 4,0 – 4,5 | 8,4 |

| 100 | 114 | 4,5 – 5,0 | 10,8 |

| 125 | 140 | 4,5 – 5,5 | 13,4 |

| 150 | 165 | 4,5 – 5,5 | 15,8 |

After the inner and outer diameters are determined, a circuit and a drawing of the trunk are made with all the turns, transitions, connections. The number of fittings and other parts is counted.

After the inner and outer diameters are determined, a circuit and a drawing of the trunk are made with all the turns, transitions, connections. The number of fittings and other parts is counted.

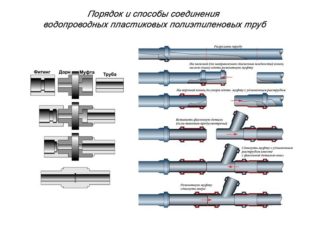

For each material, there is a joining method that ensures the tightness of the structure:

- soldering;

- screw or press fittings;

- couplings;

- welding.

Installation of polymer and combined structures is simpler and does not require the use of bulky expensive tools, so they can be done with their own hands, if desired.

For the installation of steel or cast-iron water supply, it is better to invite a team of workers with the necessary equipment who will perform the work and give a guarantee.

Operation and repair

With proper installation of water or sewer pipes, taking into account all the characteristics of the climate, soil, temperatures, the main should work the time stated in the technical specifications. Polymer structures are used up to 50 years.

If the installation was carried out with violations, a quick failure of the products is possible. It consists in depressurization or damage to pipes underground or in a house.

When depressurization is carried out, repair work is carried out: they dig pipes and find a leak. You can determine it by pumping equipment, which begins to junk. When the pump is running and water does not enter the house, there is a problem with the piping in the ground or indoors.

If the trunk is damaged due to low temperatures, cracking of the material is possible, which cannot be restored. Such areas are cut out and replaced.

Metal products must be periodically cleaned from the inside. Well, if during installation, inspection wells were installed along the pipe route. Through them gain access to the inside and using a cable to clean.

Plastic products do not need frequent flushing, as dirt does not stick to smooth walls. In addition, the pump creates pressure and speed at which the microparticles do not have time to settle and adhere.

The copper pipe is rarely cleaned. The properties of copper do not allow the sediment to linger inside, but the cost of such a water supply system is very high, it is not accessible to every owner of an autonomous water supply system. There is no need to worry about the presence of bacteria in the copper water supply, since this metal disinfects the liquid from various pathogenic flora.

Prices for pipes for water supply system include the cost of the material itself - the larger the diameter of the product, the thicker its wall, the higher the cost of one running meter. Plastic constructions are initially cheaper, metal ones are more expensive. The cost of additional elements for connecting parts of the water supply is taken into account.