The work of an external water supply system depends not only on its installation, but also on the proper selection of pipes that can be used for drinking water in a private house underground. When choosing take into account what material the pipes were made of, the climatic and geological conditions of the area on which the site is located.

Types of water pipes for installation underground

Metal products for these purposes are almost never used. Steel pipelines are rather heavy, rust quickly, and it is difficult to install them independently. Copper pipes are almost not afraid of rust, but at the same time their purchase and installation are irrational due to the very high cost.

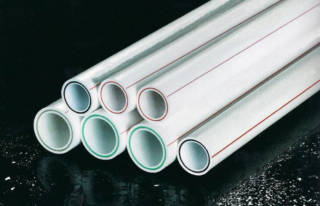

Plastic pipes perfectly replace metal structures. Polymer products are better than steel: they are not susceptible to corrosion, fistulas and leaks do not appear over time. Plastic pipe sections are inexpensive, they are easy to install, assembly can be performed without the use of special equipment. For water-supplying polymer pipes, it is easier to find fitting elements and accessories.

For outdoor water supply networks in a private house, options from various polymers are used:

| Material | pros | Minuses | Installation Nuances |

| Low Pressure Polyethylene (HDPE) | Resistance to loads up to 10 atmospheres, flexibility, ease of installation. | Fear of cold weather, the need for high-quality thermal insulation coating. | The pipe can easily be bent without much effort. To improve the quality of work, it is better to use a pipe bender. Installation is not recommended if the temperature drops below five degrees Celsius. |

| Polypropylene | Increased strength and resistance to high and low temperatures. | Lack of flexibility. | Suitable for hot water supply. Can be installed at a depth of more than two meters. Turn and bend the pipeline by means of fittings made of the same material. |

| Polyvinyl Chloride (PVC) | Low price, light weight, easy to install. | Susceptibility to high temperatures. | They are used exclusively for cold highways. Do not lay deep - PVC is not very durable. |

The metal pipe sections are made of polymer, which is additionally reinforced with aluminum. Strong and durable products are not subject to thermal expansion. Such pipes are best suited for running water underground, but are more expensive than polymer options.

Criterias of choice

Pipe products for external water supply must comply with the following indicators:

- Quality. Pipe manufacturing is carried out according to technical standards. Products must have a flat, smooth surface, without pits, creases or swellings.

- Reliability. Highways need resistance to mechanical stress, the ability to withstand high pressure.

- Environmental friendliness and safety for human health and the environment. The pipe material should not adversely affect the quality of drinking water.

- Durability. The material of the product must be resistant to wear and tear, the effects of biological processes - corrosion, rotting, the effects of rodents and mold.

- Resistance to sharp temperature changes and immunity to freezing of the soil. Even a pipe with good insulation will undergo constant thermal deformation, which should not affect its performance.

Polypropylene, metal-plastic and copper products fully meet all these criteria.However, the installation of PVC and polyethylene water supply lines is also possible taking into account the characteristics of the materials.

PVC pipelines are undesirable to be installed in hard, stony soils in a trench way. They will have to be laid in sleeves. With this type of soil, it is better and easier to use metal plastic.

When buying plastic products, you need to pay attention to the marking of the pipe. For pipelines underground, the best version of a PN10 product. PN6 models are cheaper, but their properties do not meet the specified requirements.

According to state standards, products with a diameter of 32 mm and a length of 240 cm are suitable for external work. But you can buy flexible pipes of a larger length, packed in bays.

When selecting water pipes, carefully inspect the surface. It should be smooth, without scoring and other defects. Any marriage reports of poor quality material or the use of worn equipment. Also, at your request, the seller must provide documents that confirm the quality of the products and their compliance with SanPin standards. It should explicitly state that pipe sections can be used for drinking systems.

Features of laying an external water supply

The supply pipe is laid below the freezing depth of the earth. On average, this distance is one and a half meters. If you lay a water pipe higher, the pipes may burst from frost, or the liquid will rise in them due to ice plugs.

Freezing depth is determined depending on the climate and soil type. If you do not know the indicator in the area where the site is located, go deep by 1.6 m. Thermal protection of the water supply pipe will be useful. One of the optimal methods of insulation is considered to be laying along the length of the heating cable pipeline.

It is cheaper to use insulation material. It must meet the following characteristics:

- low thermal conductivity;

- hygroscopicity;

- resistance to aggressive environmental influences;

- immunity to temperature extremes.

If the installation of the water supply line was carried out using pipes made of metal-plastic, heat insulation can be used as insulation. The insulation has a low density, which is the main advantage. But additional isolation is required, which increases the duration and cost of work. Basalt cotton wool has good quality indicators and a convenient way of laying, but at the same time it has a rather high price. Styrofoam cases are suitable for polymer pipes.

Laying a water main in the ground begins with digging a ditch, which must be dug so that it does not intersect with other communication networks and does not pass under buildings. This will allow in the future not to dig at random the territory for the search for an underground pipeline. You will know exactly how the utilities are located.

Highways are laid with the creation of a slope towards the well or borehole to ensure drainage of water from the water supply network in the process of performing conservation work. The length of the pipe under the foundation inside the house and to the source of water intake is calculated with a half-meter margin.

It is not advisable to cover the assembled water supply system with a heat insulator and to fall asleep immediately after installation. It is tested throughout the day to evaluate throughput and to check for leaks.

The arrangement of a water supply system underground is much more economical and aesthetic than land lines. With the correct selection of tubular products, the need to "blow up" the soil and repair the trunk will not arise during the life of the pipe. For plastic and metal-plastic models, it is half a century.