An autonomous water supply system is necessarily equipped with a drain valve. Thanks to this technical device of small dimensions, it is possible to prevent freezing of the system, which becomes the reason for its complete failure. Drain valves installed in water supply systems prevent the occurrence of various emergency situations.

Purpose and scope

The main task that the drainage device must perform is to protect the autonomous water supply system from freezing of fluid flows, which is transported through the pipeline. The most common critical situation is a sudden shutdown of the pumping station or submersible, surface pump during the onset of cold weather. As a result, the pipeline freezes, this leads to a violation of its tightness and integrity, breakage is inevitable.

The main task that the drainage device must perform is to protect the autonomous water supply system from freezing of fluid flows, which is transported through the pipeline. The most common critical situation is a sudden shutdown of the pumping station or submersible, surface pump during the onset of cold weather. As a result, the pipeline freezes, this leads to a violation of its tightness and integrity, breakage is inevitable.

Installation of a drain device can prevent these unpleasant phenomena. In addition, a miniature sized part prevents the consequences caused by water hammer. The use of a drain part makes the system more productive and efficient, the service life of the entire system is extended.

The principle of operation and device

The principle of operation of the drain device is as follows:

The principle of operation of the drain device is as follows:

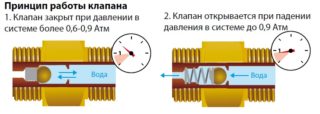

- Shutdown of the pumping equipment leads to a drop in pressure in the pipeline. When the mark reaches 0.6-0.7 bar, the drain valve is activated and naturally drains the remaining fluid from the pipeline back into the well.

- After starting up the pumping equipment, the pressure in the system rises to 1.5 bar, the valve closes.

This principle of action can effectively prevent unwanted stagnation of the water column in the pipeline system.

The automatic device is a small device in a brass body, the internal cavity is equipped with a plastic valve. When the pressure in the line drops, the valve drain opens. For the manufacture of the case, as a rule, stainless steel is used. The main structural elements:

- Composite type of housing whose parts are connected by thread.

- The locking mechanism, consisting of two movable spool plates mounted on a special rod and gasket.

- A plastic valve mounted at the outlet of the passage connector.

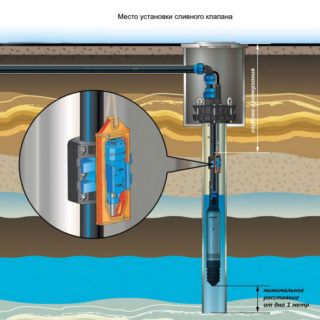

The drain valve must be installed at a depth below freezing of the soil level. The optimum installation depth is 5 meters.

When buying a device, you should not give preference to the most budgetary ones, as in the manufacture, as a rule, low-quality materials with a short operational period are used.

Criterias of choice

If the homeowner has a need to purchase a drain valve with a grid for installation on the water supply system, one must rely on the selection criteria and technical parameters of the product:

- indicators of nominal, trial and working closing pressure;

- tightness class;

- Conditional bandwidth metrics

- diameter of the landing part.

The attached documentation for the pump system or water pump contains information on the technical requirements for the drain valve and its modifications.

You need to purchase new products that were manufactured no more than 5 years ago. If they were stored in warehouses for a long time, the work of the part may be unproductive.

Mounting Features

To install the drain valve yourself, you need to familiarize yourself with the installation features. Highlights:

- Before installing the part, it is necessary to check whether the system is equipped with a filter for rough water purification. If not, during operation, the valve will constantly clog and quickly fail.

- The drain valve is mounted on the pressure line below the downhole adapter (if used).

- During installation, the trajectory of the working medium in the pipeline is taken into account. To do this, a guide arrow is indicated on the pump housing. If you neglect this rule and install the device incorrectly, it will not fail, but it will not be able to perform its task.

- In the system, the temperature of the medium must be less than the allowable temperature on the part.

The service life of the most budgetary valves with mesh and rubber seal does not exceed 3 months. To prevent this problem, it is recommended that equipment with a metal seat and a metal-to-metal seal is preferred.