The work of an autonomous water supply system is based on the efficient and economical operation of pumping equipment, which creates the required water pressure inside the network. In addition to the pump and pipe wiring, another device is installed that is responsible for turning the pump units on and off - the water pressure switch in the water supply system for a private house.

Types and principle of operation of the relay

The main type of pressure sensors is electromechanical. It consists of several contacts responsible for the automatic start of the pump and the mechanical regulator of the water pressure level, to which the electrical part of the device will respond. Manual adjustment.

The principle of operation of the device is based on the bending of the plate. She, in turn, closes one of the two contacts. One of them turns on the pump, the other turns off. The bend plate is limited by two springs, the adjustment of which is carried out manually.

One of the springs responds to high water pressure inside the water supply network, the other to the minimum set. As soon as the water pressure in the water pipe drops, the plate straightens, shorting the contact to start the pump motor. The pressure rises, the spring begins to press on the plate, which bends. Its pressure on the “start” contact weakens and, in a certain state, ceases to act. But at the same time there is pressure on the second contact, which is responsible for stopping the pump installation.

Relay adjustment and tuning

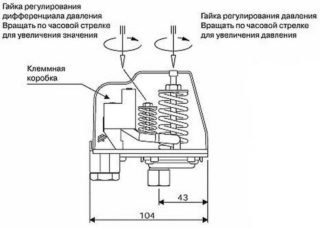

The adjustment of the water movement sensor in the pipe is made with nuts that support the springs. Increasing the compression ratio of the springs, they achieve automatic operation of the pressure switch depending on the pressure of the liquid inside the water supply system. The stronger the nuts are tightened, the more pressure the device will respond and vice versa.

Water pressure sensors, which are used in autonomous networks in suburban areas, are small-sized devices that come on sale with ready-made standard settings. They will respond to a minimum pressure of 1.5 atm., And a maximum of 3 atm. If for some reason you need to configure the sensor for the presence of water in the pipe, you must remove the cover of the device, which is attached to the body with a screw. Then tighten or loosen the spring nuts with a wrench. In place of nuts on the housing, risks are made that determine the degree of loosening or compression.

Two springs are installed in the relay design, which differ in size from each other. One has a large diameter, the other a small one. By spinning the first one, it is possible to solve the problem of controlling pressure levels — increase the nominal pressure or decrease it. By spinning the second, the problem of the superiority of large pressure over small pressure is solved - you can increase or decrease the difference between the maximum and minimum parameters.

If the pressure difference is large, and the on and off relay is installed on the accumulator, you can save on frequent switching on / off of the pump unit. It should not be allowed that the difference is less than 1 atm. It is impossible to tune the device without taking into account the maximum pressure that the pump gives out - it is strictly forbidden to tune over the set value.

Electronic sensors

This type of relay differs from electromechanical in that it cannot be manually controlled. The devices come on sale with ready-made settings. Therefore, it is very important to choose the right device for the following parameters of the water supply network:

- power and pressure of the pumping unit, special attention to the maximum pressure indicator;

- patency (productivity) of the water supply, which depends on the number of consumers.

The household relay is regulated under the minimum pressure in the range of 1.5-1.8 atm., Maximum from 2.5 to 3 atm. Electronic devices are usually mounted on hydraulic accumulators. Electromechanical can be mounted anywhere in the plumbing system. The main thing is a small distance from the pump, so as not to pull far the wiring.

The first start-up of a water supply system with a built-in electronic relay can be puzzling, because the device does not turn on immediately, but after 15-20 seconds. During this time, the sensor is automatically configured.

The electronic pressure switch can also be adjusted manually if the necessary situation arises. This is done using the buttons located on the front of the device. There is also a display on which numbers showing the nominal pressure value are displayed.

Scheme and connection rules

It is necessary to connect the pressure switch for the water supply with a submersible pump or any other strictly according to the instructions proposed by the manufacturer. The device is connected to the water supply using a fitting, at the end of which an external thread is made. To do this, screw the tee into the selected point, pre-cut part of the pipe. A sensor is screwed into the free hole of the fitting. Be sure to seal the joint using FUM tape.

There is an option when the connection is not carried out directly - the relays are installed outside the water pipe, and the connection is made with a flexible hose. This makes it possible to mount the device in a convenient place for carrying out maintenance.

Mounting in a tee does not allow you to twist the device about its axis after installation, because the final fastening is the tightening of the lock nut. The latter tightly locks the sensor in place. Therefore, it is necessary to accurately calculate the number of turns in order to achieve the correct location of the relay with maximum tightness of the junction.

The next step is to connect the pressure sensor to the pump unit. To do this, you need to choose an electric cable over the cross section, which should correspond to the power of the pump motor. For example, if the motor power exceeds 2.2 kW, the minimum cable cross-section is 2.5 mm².

To connect to the terminal box of the device, you must first remove the cover. Contacts are usually indicated by symbols or numbers. The instructions indicate exactly which contact, to which motor terminal should be connected. It is important not to make a mistake. The manual contains a diagram.

If the terminal box contains a ground terminal, indicated by the inscription "ground", or some other sign, you will have to ground the device.

Experts recommend installing one pressure gauge next to the sensor. With it, you can track the water pressure inside the water supply.

Water pressure switch - a universal device. It not only monitors the operation of the pump installed in the autonomous water supply system, but also turns it off in non-standard extreme situations, for example, when water has run out in a well or well.