Industrial enterprises often need distilled water. This is especially true for the chemical, pharmaceutical, food, and cosmetic industries. For water treatment, industrial reverse osmosis filters are used here, which purify water by 99.9%.

Application area

Cleaning with an industrial reverse osmosis filter is carried out in industries where cleaning is required that is close to distillation. Scope of technology:

Cleaning with an industrial reverse osmosis filter is carried out in industries where cleaning is required that is close to distillation. Scope of technology:

- beverage production - used to remove minerals and salts;

- production of medicines and cosmetics;

- chemical industry - reduces hydrocarbon alkalinity;

- bottled water treatment;

- production of microelectronics elements;

- purification of household liquids and wastewater;

- engineering;

- closed cycle water cycle processes.

Filtration using reverse osmosis completely displaced ion distillation from the market, which is several times greater than energy consumption.

Principle of operation

The principle of operation of an industrial reverse osmosis filter is to purify water, which under pressure passes through a membrane. Contaminants and chemical impurities do not pass through it, passing clean water.

The principle of operation of an industrial reverse osmosis filter is to purify water, which under pressure passes through a membrane. Contaminants and chemical impurities do not pass through it, passing clean water.

Ions of chemicals that are removed after cleaning:

- heavy metals;

- sodium;

- potassium;

- sulfates;

- chlorides;

- boron;

- fluorine.

The pore size of the membrane is equal to the size of water molecules. In reverse osmosis, it is possible to control the composition of trace elements. In the event of a failure of the filtration process or a deterioration in the quality of purified water, the membrane unit is blocked by force.

After completion of the filtration process, purified water, called permeate, is associated with stock water, or concentrate, as 2: 1. To obtain 1000 liters of purified liquid, the required supply volume is approximately equal to 1500 liters. Of this volume of runoff water will be 500 liters.

Types and arrangement of industrial plants

Industrial filtration system is a combination of technological devices, filtration units and shutoff valves. The main criterion that determines development is power. There are several types of osmosis:

- Low capacity plants filtering up to 5 cubic meters per hour. Of all the varieties, this is the most budget option, the membrane in them is in one case. If there is one membrane, it is located vertically, if there are several of them - horizontally.

- Medium-performance constructions qualitatively filter seawater. They differ in the number of membrane elements present in two cases, which are located in parallel.

- The most powerful and most productive version of industrial reverse osmosis contains additional load-resistant membranes to which contaminated water is supplied. After filtration, 75% permeate remains. They are a complex technical object and are controlled by hardware.

In industries, a different volume of pure liquid is required, therefore, for each goal, an individual selection of industrial reverse osmosis is required.

Criterias of choice

There is no single standard type of osmotic installation that would suit every enterprise. The filter is selected depending on the quality of the incoming water and the required performance. To choose what type of installation is needed, you need:

- Based on the level of contamination of the incoming water, establish the necessary type of membranes and their number.

- In accordance with the capacity and type of contamination, select the pump according to the performance parameters.

- Determine the necessary type of equipment for pre-filters.

You can select an osmosis system only after clarifying the initial parameters. One of the main selection criteria is the scope of permeate, since the chemical characteristics for different industries can be diametrically opposed.

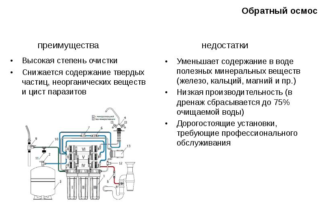

Advantages and disadvantages

The quality of purified water, close to distilled, is the most important advantage of the filtration process. Permeate can be consumed for drinking and cooking.

The quality of purified water, close to distilled, is the most important advantage of the filtration process. Permeate can be consumed for drinking and cooking.

An advantage can be considered the ability to vary the methods and degree of water purification. It is possible to understaff the device with an ultraviolet lamp, mineralizers or other devices required in the production.

The disadvantage is the large percentage loss of permeate volume in relation to the incoming concentrate.

Reverse osmosis cannot hold certain types of ions. These include chlorine and herbicides.

The chemical composition of permeate is depleted. The filtered liquid is harmless to humans, but also useless. It lacks all the nutrients and essential minerals.

Cost of equipment

Prices for industrial reverse osmosis plants are proportionally dependent on the required individual production characteristics. An installation with a capacity of 500 liters per hour can be purchased for less than 130 thousand rubles.

A foreign-made system that removes up to 98% of pollutants and 99% of unnecessary bacteria, with a capacity of 500 liters per hour and receiving up to 40% of permeate, costs 140 thousand rubles and more.

A highly efficient industrial filter of Russian production with two membranes, with a productivity of 450 liters per hour, can be purchased from 145 thousand rubles.

Industrial reverse osmosis is widely used in a wide variety of manufacturing fields. Filtration of this type is considered the most universal, effective and promising.