Suburban areas - this is the need for the installation of autonomous communications, including water supply. Wells are often dug as a source of water. But they require a quality arrangement of their mines. Here, eternal plastic wells for drinking water are very popular. Moreover, the design can be mounted as a team to the desired depth, and welded.

Where to use plastic wells

Structurally, such a structure is a pipe with a cross section from 31 to 100 cm. Its outer walls can be smooth or corrugated. The latter option is especially convenient, since the corrugation acts as stiffeners in moving soils.

More often polymer wells are used in such cases:

- arrangement of water supply systems;

- installation of water disposal from the site;

- sewerage compartments of a septic tank;

- installation of storage tanks for collecting water for irrigation;

- additional sealing of an existing source with a shaft made of concrete rings (here a pipe of the desired diameter is simply inserted inside an already equipped well).

Structures made of polymer on the water supply can be sealed (with a bottom) or without it. Most models have a screwed bottom.

Types of Plastic Wells

All polymer containers for the source mine device are divided into types according to the type of manufacturing material:

- Polyethylene. Finished structures have a high level of density. The use of polyethylene water wells is especially important where there is a risk of contact between the source shaft and aggressive media. But from the outside it is desirable to strengthen them with corrugation, since the polymer has high flexibility and can be subjected to static or dynamic effects of the soil.

- Polyvinyl chloride. Durable material, but negatively reacting to subzero temperatures. When combined with static pressure on the well from the ground, the product may burst. PVC is inert to aggressive environments.

- Polypropylene. The most durable, flexible material for making water wells. The polymer is not afraid of temperature changes.

By type of construction, all plastic tube-shaped structures are divided into solid and prefabricated.

One-piece wells are seamless pipes of the right diameter or welded. If necessary, they are provided with a bottom element for filtering the incoming liquid, a tray, a neck. For seamless products, the following parameters are characteristic:

- wall thickness - 6-12 mm;

- height - 1-4.5 m;

- section - from 95 cm.

Seamless designs are most relevant for the construction of the source mine, as they have perfect tightness. Prefabricated structures are mounted from the right amount of durable polymer rings, similar to concrete products. The principle of docking is screwing. With this method of constructing a well, a sufficiently deep shaft can be assembled. But it is important to remember: the more junctions, the higher the chances of sooner or later colliding with depressurization.

Advantages and disadvantages

Polymeric products for the device of a drinking source have several advantages over similar designs, but from other materials. These include:

Polymeric products for the device of a drinking source have several advantages over similar designs, but from other materials. These include:

- Relatively light weight, which simplifies the installation process.

- Tightness of the mine subject to the use of seamless pipes.

- Inertness to decay, corrosion, development of bacteria.

- Favorable cost in comparison with a brick or reinforced concrete rings.

- The presence of external stiffeners, which ensures the strength of the structure in the ground.

- Low thermal conductivity. This ensures that there is no freezing of water in the source.

- Large assortment of tube and ring sizes.

- Long term of operation (from 50 and more years).

The disadvantages, more precisely, some features of the operation of polymer products include the need for regular maintenance of the filter element.

Installation and operation

When installing polymer pipes as a mine for a source, it is important to adhere to the basic rules:

When installing polymer pipes as a mine for a source, it is important to adhere to the basic rules:

- It is allowed to use plastic products only in those regions where seismic activity does not exceed 7 points. Otherwise, during the movement of the soil layers, the polymer may burst.

- The maximum depth of the plastic shaft should not exceed 6 m.

- Backfilling of the structure is carried out when the well is completely filled with water. Otherwise, the polymer may not withstand bilateral pressure (from soil and water).

- Filling can be done with gravel or sand. Better is the last option.

- You can put polymer wells in any soil (dry, wet, sand, etc.).

- It is forbidden to use plastic elements in regions with winter temperatures below -50 degrees.

Well installation steps:

- Digging the mine shaft of the desired depth. Its cross section should exceed the diameter of the polymer pipe by 15-20 cm. This gap is allotted for backfilling.

- The bottom of the pit must be tamped and covered with a layer of geotextile. It is also compacted and additionally covered with a layer of fine-grained gravel.

- A well shaft is assembled from separate rings or a pipe is simply prepared.

- The design is lowered into the pit, aligned vertically.

- A layer of river pebbles is additionally poured onto the bottom.

- Fill the well with water. As soon as he reaches the maximum, perform his backfill. It is better to use slightly moist sand mixed with soil for this. When backfilling, they must be carefully rammed in layers.

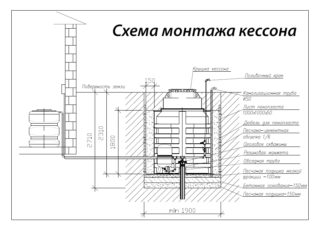

It remains to arrange pumping equipment that will supply water to the house. It is better to mount a special caisson under it (if the pump is surface). To maintain a constant pressure in the system, experts recommend using a storage accumulator. For a family of 3-4 people, it is enough to install a tank for 25-50 liters.

Cost of materials

The price of plastic pipes for a drinking water well depends on the size and the material from which they are installed. Approximate prices for the Moscow region:

- corrugated pipe d 900 mm; h-1500 - from 15 100 rubles / pcs.;

- corrugated pipe d 900 mm; height - 2,200 mm - from 16,200 rubles / pcs .;

- Rodlex ring diameter 900 mm with a height of 500 mm - from 4 300 rubles / pc.;

- a ring with a height of 1,000 mm - from 8,500 rubles / pcs .;

- a ring with a height of 1,500 mm - from 12,600 rubles / pcs.

If you buy a ring with a sealed bottom, it will cost about 2-3 thousand rubles more.