The pump station DAB is a reliable and fully operational device. Quality product made in Europe. This type of equipment combines traditional design solutions with innovative developments.

Purpose and device

DAV pumping stations provide water for civil, industrial or agricultural systems. The use of booster models - increasing pressure, pumping fluid from wells, wells, surface sources. They are used to meet the needs of private homes. Fire fighting units are operated in conjunction with fire extinguishing systems.

DAV pumping stations provide water for civil, industrial or agricultural systems. The use of booster models - increasing pressure, pumping fluid from wells, wells, surface sources. They are used to meet the needs of private homes. Fire fighting units are operated in conjunction with fire extinguishing systems.

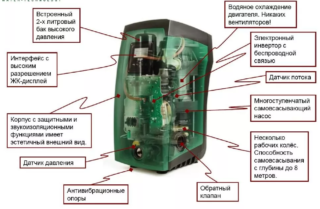

The composition of the DAB pumping station includes the following instruments and appliances:

- membrane tank;

- pump;

- pressure gauge;

- pressure switch;

- adapter fitting;

- connecting hose.

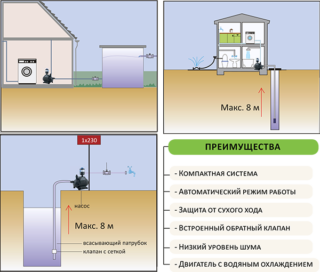

DAB station operates on a very simple principle. From the selected source, pumps water into the membrane-type accumulator, which gives it to the water supply. The control unit monitors the pressure in the tank. When it decreases, the pump turns on, and when it reaches the required level, it turns off.

Specifications

DAB pumping stations are capable of lifting water from a depth of at least 8 m. It may contain air bubbles, a small amount of sand. The temperature of the pumped water should be within the range of -10 ... + 35 ° С.

The technical features of the equipment are called:

- device cooling - water without a fan;

- the presence of an aesthetically attractive housing with soundproofing and protective functions;

- the presence of a convenient interface and high-resolution LCD;

- the presence of anti-vibration mounts.

The device features simple installation and adjustment of basic functions. It has reliable protection against dry running. The operation of the device will be profitable due to the presence of modern energy-saving technologies. At the same time, it is considered powerful and compact.

The lineup

DAB pumping stations are represented on the market by a variety of models with different characteristics.

DAB E.Sybox Mini

The devices of the Mini series are small, which allows them to be placed under the sink. The pump station can be placed vertically, horizontally or suspended on a wall. The unit operates with a minimum noise level of 45 dB. This is achieved by placing the pump inside the tank itself.

The model is able to give a water head of 50 m at a flow rate of 80 l / min. The maximum suction depth is 7 m.

Aquajet 82 M

Specifications:

- head - 47 m;

- there is thermal protection, pressure gauge;

- water consumption - 3.6 cubic meters m / h;

- horizontal type of installation.

The body of the pumping station is made of cast iron. This ensures its long service life.

Aquajet 102 M

The standard pressure of the pumping station is 53 m, the water flow rate is 3.6 cubic meters. m / h The type of attachment of the unit is horizontal. Additionally equipped with a pressure switch, pressure gauge, thermal protection. The device is great for continuous operation.

Aquajet 112 M

The system is equipped with a pressure switch, which automatically turns it on and off. The device creates a pressure of 61 m at a flow rate of 3.6 cubic meters. m / h The pump station is suitable for continuous operation, but lacks protection against dry running.

- Aquajet 82 M

- Aquajet 112 M

- Aquajet 102 M

- E.Sybox Mini

Criterias of choice

When purchasing devices under the brand name DAB, the following should be considered:

When purchasing devices under the brand name DAB, the following should be considered:

- type of exploited source - well, well, surface water;

- purpose of the pumping station - for domestic, industrial, agricultural use;

- well debit - should be greater than the unit’s hourly output.

When choosing pumping stations, it is taken into account that their housing is made of stainless steel or cast iron. The use of such materials guarantees a long service life and reliability of the unit, its attractive appearance. In this case, the cast iron body produces an additional soundproofing effect.

Features of operation and maintenance

To ensure the effective functioning of the pumping station, it is important not to allow it to run dry and to adhere to other recommendations:

- metal connectors should not be used on threaded holes;

- the unit is placed on a flat, dry place, away from flammable objects;

- the diameter of the hoses must be less than the size of the inlet and outlet of the pump.

Maintenance of the equipment is to prevent freezing of water in it. If in the room where the unit is located, the temperature drops below 0 ° C, it is necessary to drain all the liquid and transfer it to a warmer place. When performing cleaning or any manipulations with the station, it is important to disconnect it from the network.