The quality of piped water, unfortunately, leaves much to be desired. As a result, special cleaning filters are becoming more popular in the Russian market. Subjecting water to several stages of purification, it can be used not only for domestic but also for food purposes.

Storage tank for reverse osmosis system

When resorting to household purification of drinking water with a purifying filter, it is important at all times to have access to clean liquid to select it in the required volume without additional hassle and waiting. However, fine filtering is not a fast process, and only weak pressure is visible at the output. As a result, there is a need for regular replenishment of purified water.

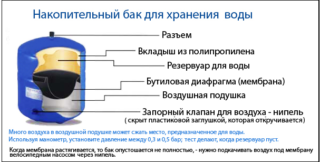

To prevent this problem, a storage tank was invented, which is mounted together with the design of a cleaning filter. The tank is intended for the selection and storage of already purified liquid. The outer case is made of high-quality metal or environmentally friendly plastic, the inner part is identical for all models - a hydraulic accumulator is installed.

The principle of operation and device

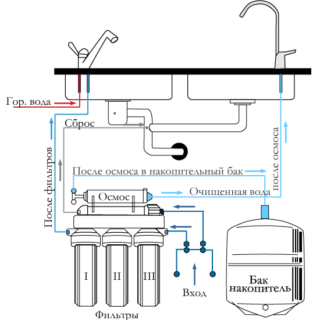

Visually, the reverse osmosis storage tank is a barrel of cylindrical shape, which is made of plastic or enamelled steel with a special hole for connection to the filtration system, as well as to the tap at the sink. The connection is provided by a special valve, which allows you to take fluid directly from the filter station at any time or shut off the flow to the reverse osmosis tank.

In the reverse osmosis system, the entire inner surface of the barrel is covered with a rubber membrane - a diaphragm, which divides the entire cavity into two components:

- At the bottom of the barrel is compressed air, in an empty tank the pressure is approximately 0.5 atmosphere. It is downloaded by the manufacturer at the manufacturing stage.

- The upper part of the storage tank contains purified water from the filter.

As the upper chamber fills with water, the diaphragm bends, increasing the working pressure in the lower part of the barrel.

The content of compressed air in one of the parts ensures the expulsion of water with the tap open.

After taking a certain amount of liquid, the main task of the system is to replenish the water supply to the maximum possible value. The process of water purification through filters is suspended as soon as the storage tank is 100% full. The discharge of purified liquid into the sewer is not carried out.

The upper part of the storage tank is additionally equipped with a special plastic container designed to store purified water, which prevents direct contact with the metal case. This design feature extends the life of the equipment, and is also advisable on the part of hygiene safety.

Installation Features

There is a wide variety of reverse osmosis systems, each with its own characteristics during installation. An example of mounting a five-stage purification filter with a storage tank:

- Open the package and check for parts, get acquainted with the functionality.

- Choose the most suitable place for installation. As a rule, the tank and filters are installed under the sink.

- Installation of an additional tap for purified water from the storage tank.

- Connecting the device to the pipeline and plunging into the sewer system.

- Install the valve on the drive.

- Installation of the filtration unit.

- Checking the health of the system.

Before using purified water for food purposes, the tank must be washed several times. This will remove dust and chemical residues.

The main causes of malfunctions and their solutions

The service life of the storage tank ranges from 3-4 years. In this case, it is required to regularly disinfect the cavity and follow the maintenance schedule.

The service life of the storage tank ranges from 3-4 years. In this case, it is required to regularly disinfect the cavity and follow the maintenance schedule.

It is worth familiarizing yourself with the most common malfunctions that owners of the unit have to face.

Reduced filter performance

The problem is accompanied by a weak pressure from the tap. It is difficult to get the required amount of clean water.

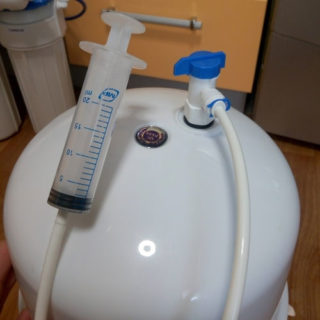

To fix the problem, check if the storage tank is full. If the container is full, but the water still does not flow, this indicates a low working pressure in the lower chamber with compressed air - it is not enough to act on the membrane.

To solve the problem, you need to adjust the pressure in the air chamber, for this there is a special nipple on the front side of the barrel. With its help, it is possible to pump air up to a nominal value with a pump.

Water enters from the nipple when trying to pump air into the lower compartment

If water began to flow from the bottom of the barrel, this indicates a violation of the integrity of the separating membrane. To solve the problem, a complete replacement of the reverse osmosis storage tank will be required. You need to buy equipment that, according to all technical parameters, is suitable for the filtration system.

After installing a new cylindrical barrel, you need to carry out the following manipulations:

- Open the tap on the tank so that it begins to fill with clean water.

- Wait until it is full. When the cleaning is completed, the drain of water to the sewer stops.

- Open the tap until the container is completely empty.

This simple procedure allows you to remove particles of contaminants and chemical sprays in the interior of the unit. After washing, the equipment is used in the usual way.

When pumping the working pressure in the lower part of the barrel, the tap must be open. If all the liquid escaped from the tank during the process of pumping air, and then air began to escape intensively, this indicates the presence of a hole in the diaphragm.

How to flush a reverse osmosis tank

Flushing the storage tank is required regularly, not only in the event of a breakdown. It is not possible to wash the inside of the tank mechanically, so special chemical disinfectants must be used.

There are cases when users begin to be alerted by an unpleasant aftertaste or smell of purified liquid. It is important to establish the cause of this phenomenon correctly. Most often this occurs due to a malfunction of the membrane or a breakdown of the membrane holder. Another possible option - a tank filled with water was not used for 2-3 weeks or more.

To carry out disinfection of the internal cavity, it is best to use hydrogen peroxide, chlorine or iodine. The most effective are the preparations, which include chloride compounds. After such disinfection, it is important to carry out a high-quality washing with full filling and emptying of the container, and repeat the procedure at least two times. To achieve an effective result, flushing should be carried out only with purified water, and not from a water tap.

The storage tank simplifies the use of purified water, however, for proper operation, it must be properly looked after. Instructions for use are attached.