Summer cottages are silted up faster. If water is not regularly pumped out, the strainer is not washed naturally. At the same time, the water pressure drops, and a muddy dirty liquid begins to flow into the tap. The problem is that pumping equipment also suffers because the casing is clogged with sand or clay. If an ordinary sand well is cleaned on average once every 5 years, then the country should be inspected more often.

The main causes of clogging water wells

Sources are infiltrated in the following cases:

- During installation, workers forgot to isolate the bottom layer of soil. Coarse gravel is usually used so that dirt does not rise during the operation of the pump.

- Incorrect pump selection. The vibrational type creates strong vibrations, due to which small particles of dirt move and fall into the house with the liquid. Its residues settle on the strainer or in the equipment case.

- Breakdown inside the well. There were cases that when using a plastic casing, it was exposed to quicksand - moving sands from the aquifer. At a depth below 25 meters, plastic is ineffective and often bursts, resulting in dirt entering the pipe.

- Incorrect well design. When drilling, workers violate the terms of the project, so the source productivity is less than expected.

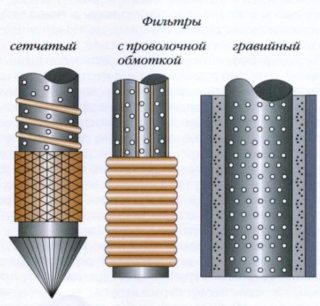

- Filter overgrowth with sludge, clay, salt deposits or iron ions.

- Filter breakthrough due to high speed of water movement.

- Substitution of the clay layer with clay due to soil movements. As a result, the filling of the well deteriorates or the water disappears altogether.

- Improper source operation. Siltation can occur in the interval from 2 to 3 months, if it is not pumped. Depending on the condition of the filter and soil composition, this process can last up to a year.

Poor water supply is not always associated with the condition of the well. Wear of pumping equipment is one of the reasons for the pressure drop. In submersible units, due to sanding, the blades are erased and productivity drops by 25-30%.

Before inspecting the well, you need to get the pump, disassemble it and assess the condition of the internal parts of the structure. It may be sufficient to change or repair the instrument. At the same time, the water quality will be good, but the amount of fluid entering the tap will become less.

Methods for determining well failure

Specialized firms use the video diagnostic method, which allows you to view each area on a computer monitor. After that, an estimate is drawn up for the required amount of work. The method is error-free, but only specialists of the company have cameras that can work under water.

It is possible to independently determine the breakdown only by examining each individual unit - the pump control unit, the unit itself, pipe connections, the well and its components. If water is detected in the caisson, the pump may have been shorted due to depressurization. In the winter season, ice accumulates on the inner walls of the pipes, the operation of the water intake system is disrupted.

Unprofessional intervention is able to completely stop the source, so for diagnosis and repair it is better to call specialists with the necessary equipment. After the examination, you can decide whether to operate this well further or cheaper to drill a new one.

Methods of cleaning wells for water in the country and the choice of method

In the arsenal of specialized firms there are several ways with which you can clean the well from silt and sand, deepen it, change the filter - these are mechanical devices and the chemical method. You can apply it yourself:

- bastard;

- dual pump fluid pumping scheme;

- vibration pump;

- airlift - the formation of a foamy-air mixture.

Which of these methods to choose depends on the cause of the breakdown and deterioration of water quality, as well as on the condition of the shaft of the mine. The chemical method should be applied under the supervision of specialists and only after the volume of liquid has been determined.

Mechanical cleaning method

To mechanical methods include:

- ruffs and scrapers that remove salt deposits and clean the walls of the pipe;

- electrohydroshock;

- ultrasound exposure;

- microexplosion.

Traffic jams from mineral deposits can be removed mechanically, then pump out all the liquid with residual substances to the surface. After the well is filled again, it will be possible to operate it. Scrapers are selected according to the diameter of the pipe and lowered by rotating movements. Special machines are used to clean deep wells. It should be possible to extend the pipe with additional sections as it dives.

A low-power explosion is used if an aquifer rises or a layer of clay builds up on it. Hydro pulse cleaning is a similar method, but in this case, special equipment is used, which is lowered to the bottom. A water hammer flushes sediments and widens aquifers.

Chemical exposure

You can dissolve deposits by the acid method. To do this, measure the amount of water in the source and calculate the required amount of reagent. Then it is poured into the mine and after a while all the liquid is pumped out.

This method cannot be used without special knowledge, since an excess of chemicals can poison all the groundwater in the area. Citric, acetic, and ascorbic acids are used, as well as xanthan gum, sodium benzoate. In difficult cases, stronger acids are used.

The method is used with an excess of lime, iron. After purification, water is taken for analysis to exclude the presence of chemicals in the liquid.

Bailer

This is a pipe with a diameter less than the casing, with sharp notches at the end. Using it, you can remove sand, clay, sludge from the bottom of the well and facilitate the access of fluid through the filter.

The method is primitive and slow, but safe. The pipe is lowered down and scrolled, at which time a precipitate accumulates in it. The valve at the end prevents the spilling of dirt back into the well. At one time, you can raise from 0.5 to 2 kg of sediment, depending on the diameter of the shaft.

The method is suitable for shallow sand wells. With it, you can annually clean country sources for prevention, but before lowering the pipe, you must raise the submersible pump.

Dual pump method

Water flushing of wells is possible by a double pump method. To do this, a fire hose or pipe connected to the pump is lowered into the shaft. He will pump fluid into the well under pressure. A submersible pump, on the contrary, will pump it out. The essence of the method is to thoroughly shake up all the dirt and pump it to the surface.

In order not to flood the landscaped area, you can call the scavenger machine and immerse the dirty liquid in the canister. The circular method is also used: dirty water from the well enters the barrel, from which, after filtration, is pumped back into the well by an external pump. This is a more economical cleaning.

External equipment must have sufficient power to provoke the movement of liquid below.

Airlift method

It consists in supplying air from below to the shaft. As a result, a foamy mixture is formed, the air will begin to rise to the surface and pull all the dirt - sand, silt, clay.At this time, the pumping equipment must operate at full capacity to prevent debris from settling down again. If the flow rate of the well is small, an external pump is additionally installed and fluid is pumped into the well.

Vibration Cleaning

For cleaning by vibration method, you can use the pump "Kid". It is lowered on a cable to the very bottom, where the mud layer is located. During operation, the device creates a strong disturbance of the liquid and pumps it along with dirt to the surface. So that the device does not burn out, it is periodically removed and clean water pumped, then allowed to cool and again begin to work.

There are special pumps for dirty water - drainage or fecal. You can use them, in addition to the fecal there is a cutting mechanism, and they are more hardy when working with dense drains.

Blockage prevention

First of all, it is necessary to secure the head of the well so that dust and debris do not fall from the outside. It is not advisable to use vibration pumps constantly - they shake the liquid strongly, then the particles settle on the filter and clog it. Vibration units are more suitable for working in a well.

First of all, it is necessary to secure the head of the well so that dust and debris do not fall from the outside. It is not advisable to use vibration pumps constantly - they shake the liquid strongly, then the particles settle on the filter and clog it. Vibration units are more suitable for working in a well.

Wells that are seasonally operated should be cleaned at least once every 3 years. With a certain soil composition, 3 months can be enough for the filter to become overgrown with salt deposits and petrified.

The filter in the wells on the sand is installed with a minimum cell size, sometimes the filter zone is wrapped with geotextile. The material has worked well in wells with regular pumping.

So that organic matter does not get inside and rotting does not start, it is advisable to close the top of the shaft with a dense cloth, and then set the head.

The only variety of wells that are least in need of repair and cleaning is artesian springs, but the price of drilling and equipping them is quite high.

Well cleaning prices are determined by the volume of work and the cost of consumables, such as chemicals. Self-flushing the well will cost free if the work is done carefully without damaging the casing.