Arrangement of a water supply and sewage system in private and country houses is a laborious process that requires a lot of physical and financial costs. It is not enough just to develop a source of clean water. It is necessary to establish the process of its delivery to the surface. Only special submersible pumps can handle this. The most common types of centrifugal water stations, they work by rotating a special wheel.

Purpose and principle of operation

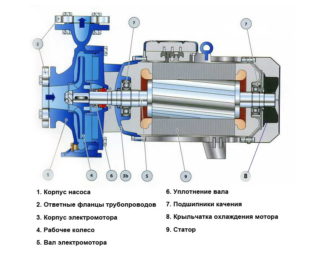

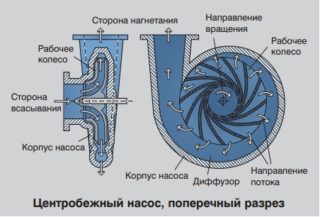

Deep centrifugal pumps for water from the well perform the task by applying centrifugal rotation forces that use the impeller, consisting of two alternately connected disks. The latter form the main contour of the rotating wheel, and thanks to their interaction, water in the chamber is pumped.

Deep centrifugal pumps for water from the well perform the task by applying centrifugal rotation forces that use the impeller, consisting of two alternately connected disks. The latter form the main contour of the rotating wheel, and thanks to their interaction, water in the chamber is pumped.

The principle of operation of the equipment is extremely simple. With the active rotation of two disks, a rarefied pressure zone is created, which draws fluid through the inlet pipes.

Primitive operation technology allows pumping large volumes of water, providing the necessary pressure in water taps. The advantage of simplicity of design still lies in the minimal probability of breakdowns. Downhole centrifugal type units have high power, therefore they are able to lift the fluid from great depths, while in operation they are almost silent.

The equipment has one drawback - susceptibility to impurities. The quality of the water flow must be high, otherwise, solid impurities when entering the hydraulic pump will disable it. Before installing this kind of pump at home, conduct water analysis in the well. You will have to install vibrational analogues if solid impurities are more than 100g / m3.

Pump manufacturers

On the Russian market, there are more than two dozen manufacturers of pumping equipment. The most popular borehole electric pumps include:

- Aquarius (Russia);

- Water cannon and Jumbo (Russia);

- Whirlwind (Russian brand, however, assembly takes place in China);

- Wilo (Germany);

- ZDS (Italy).

In terms of cost and build quality, pumps for wells with drinking water Vodomet or Aquarius are acceptable. Even at the development stage, the Russian manufacturer adapted the equipment to Russian conditions. European recognized brands have long established themselves as a guarantee of quality and high performance, but the price is not suitable for everyone.

Types of discharge units

Structurally, centrifugal pumps are:

- semi-submersible;

- superficial;

- submersible.

Surface equipment works according to the principle of suction effect. They are installed on the ground near the source, water is pumped out using a hose. The process of application and maintenance of this type of equipment is greatly simplified. However, in technical characteristics they are inferior to submersible models. A medium-sized surface pump is capable of providing a head of 30 m and pumping liquid at a depth of not more than 12 meters. As practice shows, in most cases this is not enough.

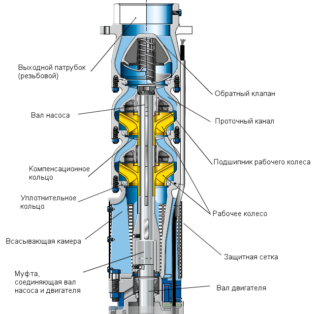

Submersible pumps are in the form of an elongated cylinder. They are mounted directly in the water source; during operation, the unit must be in a humid environment. This kind of centrifugal pump for wells is in great demand due to its high power and reliability. If the water depth is 20 meters or more, the installation of a submersible pump is almost always considered.

Semi-submersible equipment is not very popular. The unit is based on a float stabilizer, due to which it is possible to install the pump in a semi-submersible state (the working and suction parts are immersed in water, and the engine is located above the surface of the water).

Semi-submersible pump models are larger and weaker in power than submersible units. They are used only in extreme cases, because they are difficult to install and operate, are characterized by a large diameter.

By the number of stages, centrifugal pumps are divided into multistage and single-stage. The latter consist of only one impeller. But it can have impressive dimensions. Single-stage units are rarely used and, as a rule, only in surface pumps.

Multistage equipment on each axis contains several impellers. Submersible submersible pumps can pump water at the same time with 7 wheels. And this is not the limit. Engineering calculations and observations show that the device works better and wears out less if many wheels are involved at the same time.

According to the type of immersion depth, operating position, water centrifugal stations are divided into deep and standard. This classification applies to submersible models, since surface pumps, by definition, can produce fluid from a maximum of 12 meters. Standard models are capable of operating at depths of up to 50 meters. Depth units can lift water from 100-150 meters.

Criterias of choice

When purchasing pumping equipment, it is necessary to correctly calculate the necessary performance and power. It is worth refraining from buying an overly powerful unit, since most of the time it will work idle. Excessive power consumption and constant on / off disable the equipment.

For the optimal choice of a well pump, you need to know:

- The height of the lift, that is, the depth of immersion of the equipment, as well as the distance between the ground and the highest water outlet.

- The required amount of water that the well will have to give out.

- The presence or absence of an additional pumping station for pumping water and a hydraulic accumulator.

- Diameter of casing.

- The length of the water supply is not only in the house, but also on the street.

Prices for submersible centrifugal pumps for wells in the Russian market start at 7-9 thousand rubles and this is far from the limit.

Installation and connection, operation features

When the well is ready, you need to proceed with the installation of pumping equipment. The installation algorithm is as follows:

When the well is ready, you need to proceed with the installation of pumping equipment. The installation algorithm is as follows:

- A pressure hose is connected to the pumping station, which is also connected to the power cable by means of clamps.

- To immerse the equipment to the required height, a metal cable or nylon cord is attached to it. The lower part of the pump housing is equipped with an eye.

- The unit is lowered into the well and the upper part of the cord is attached to the beam mounted on the surface.

- The power cable is connected to the control unit of the station and a test run is performed.

In order for the equipment to serve for a long time without loss of productivity and power, it is necessary to observe the operating features that are announced in the instructions for use. These include the temperature and composition of the pumped medium, the degree of contamination of the liquid, as well as the stability of the power supply.

Advantages and disadvantages

Centrifugal equipment has many advantages compared to other types of pumps. The main ones: small size and weight, high performance and power, durability and reliability, the ability to work with liquids, which include solid particles.

If we talk about the shortcomings, it is necessary to highlight the difficulties in maintenance and repair, especially when it comes to semi-submersible or submersible pumps.Due to operation in a humid environment, the housing must remain airtight.

When buying pumping equipment, you need to familiarize yourself with all the accompanying documentation and a warranty card. It is recommended to purchase from official representatives of pumping equipment manufacturers or in specialized stores.