The quality of drinking water directly affects human health and life expectancy. Therefore, proper water treatment is so important both in private estates and in industrial enterprises. One of the effective types of equipment in the fight against impurities is an aeration column for cleaning water from iron. This method allows you to eliminate particles of Fe2 as much as possible and significantly improve the color and smell of the liquid.

What is aeration of water and the scope of the method

Aeration is called a special process, which implies the saturation of water with oxygen, its peculiar ventilation and softening. Due to the oxidative processes that occur during this process, the iron molecules take on the form of suspensions (a trivalent insoluble compound visible to the human eye), which can be removed. With the help of oxygen, hydrogen sulfide and carbon dioxide are also eliminated from the water.

Aeration is performed either by spraying the liquid, or by passing oxygen bubbles through it.

This cleaning method is used:

- in biological VOCs that process wastewater to support the functioning of beneficial bacteria;

- at water treatment plants, in municipal VOCs, rotary aerators are more often used;

- for proper treatment of water from the well, if it is saturated with iron or hydrogen sulfide;

- pharmaceutical, food industry;

- Agriculture;

- fish farms, artificial pools - they use a floating turbo aerator in the form of a small catamaran;

- home aquariums - for these purposes it is better to use a ceramic aerator, which neutralizes the carbon dioxide accumulated in the tank.

After soluble impurities take the form of suspensions, they are removed using special filters. If this is not done, particles of garbage will disable the operation of the pumping equipment, pollute the bottom of the storage tank.

Methods and principle of action

Three methods of mechanical treatment of water using aeration are distinguished:

Three methods of mechanical treatment of water using aeration are distinguished:

- Non-pressure. The cheapest way to saturate a liquid with oxygen. It means simple settling of the collected water in the tank. Over a period of time, its entire volume will be saturated with oxygen and iron will precipitate in a rusty precipitate. This method, in addition to simplicity, does not give anything positive. The owner of the site is forced to use only the upper part of the treated medium. The bottom must either be drained or passed through additional filters. In addition, with such aeration of water, it is necessary to regularly wash the walls of the tank from accumulated blooms, mucus.

Pressure. A method using special installations that inject air into water. Here, two more additional methods of automatic liquid processing are distinguished - compression and electrochemical. In the first case, a special column of several liters is used. It comes with a compressor for aeration of water in the treatment system. It pumps air bubbles into the column. The liquid treated in this way is transported further by means of a pump to installations with deferrizers to neutralize suspended particles. The compression method for treating liquids is noisy. In addition, it is more difficult to preserve such a set station for the winter. The electrochemical method is characterized by compact installations, high efficiency, the ability to quickly freeze the installation in the cold season (with a simple cottage). In addition, for the electrochemical method of aeration, a low percentage of waste discharges into the sewage system is also inherent.In operation, such a station is the most silent. Its service life is many times longer. Water purification from impurities occurs due to active atomic oxygen, which is released on titanium electrodes. But it is worth being careful, since hardness salts accumulate on them. Therefore, the electrodes need to be changed often.

Pressure. A method using special installations that inject air into water. Here, two more additional methods of automatic liquid processing are distinguished - compression and electrochemical. In the first case, a special column of several liters is used. It comes with a compressor for aeration of water in the treatment system. It pumps air bubbles into the column. The liquid treated in this way is transported further by means of a pump to installations with deferrizers to neutralize suspended particles. The compression method for treating liquids is noisy. In addition, it is more difficult to preserve such a set station for the winter. The electrochemical method is characterized by compact installations, high efficiency, the ability to quickly freeze the installation in the cold season (with a simple cottage). In addition, for the electrochemical method of aeration, a low percentage of waste discharges into the sewage system is also inherent.In operation, such a station is the most silent. Its service life is many times longer. Water purification from impurities occurs due to active atomic oxygen, which is released on titanium electrodes. But it is worth being careful, since hardness salts accumulate on them. Therefore, the electrodes need to be changed often.- Ejection. The venturi assembly acts as an ejector. When fluid is transported through it, air is simultaneously sucked into the impeller. Due to this, water is treated with oxygen. Despite the fact that ejection plants operate without electricity consumption, they are in low demand. The reason for this is the lack of effectiveness of the mechanism. Strong pollution does not give in to it.

The method of aeration of liquids for a private house is selected depending on the financial capabilities of the family, type of residence (permanent / temporary). After saturation of water with oxygen, its high-quality filtration is important.

Installation of water aeration systems

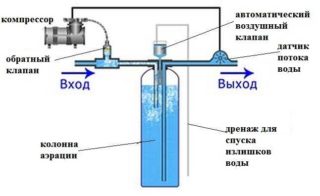

A mechanical (compressor) water aeration system with a deferrizer has several working units:

A mechanical (compressor) water aeration system with a deferrizer has several working units:

- Aeration column for collecting water. It has the appearance of a high cylinder made of fiberglass reinforced.

- Counter (flow meter).

- Compressor.

- Air safety valve. It works to remove gases and excess oxygen from the storage cylinder.

The compressor pumps oxygen into the flask, where the gas mixes rapidly with the liquid. Its molecules displace all divalent impurities and gases from the water. Then the processed medium moves to special filters. Here, all suspensions are removed, and a clean liquid is already supplied to the water supply.

The non-pressure aeration system is designed as follows:

- The large tank is equipped with a special valve. It controls the flow of fluid into the tank. It is advisable that the tank is half full. This allows the air to mix more intensely with the molecules of the moist environment.

- The discharge fan is responsible for supplying air to the tank, the exhaust fan removes oxidized gases from the tank.

Also, for non-pressure installations, special sensors are provided that monitor the on / off of equipment: fans, inlet and outlet pipes, discharge of waste fluid. Additionally, such stations can be equipped with a jet crushing function.

An aeration blower is often used in septic tanks to enhance bacterial activity.

Electrochemical equipment has the following working nodes:

- electrolyzer with cathode and anode;

- continuous current source;

- nozzles for supplying and discharging liquid;

- an electromagnetic processing unit connected to a continuous current source.

When water enters the reservoir, the unit connected to the power supply provides a change in the field voltage synchronous with the level of its rigidity. Thus, the iron removal of water and control of energy consumption occur.

Advantages and disadvantages of the method

For aeration as a way to purify water in aquariums, ponds or taken from a well / well, the following advantages are characteristic:

- Oxygen safety. The gas used to process the medium is non-toxic, free, and has a quick oxidative effect. Oxygen does not form compounds hazardous to humans.

- When using pressure aeration, it is possible to seriously reduce the dimensions of the plants. In turn, this allows you to save space on the site / in the house, which can not be said when using pressure-free installations.

- No need to use additional expensive reagents for high-quality water treatment.

- Full automation of the process. This frees the master from labor costs, the need to control the operation of treatment systems.

- A clear installation diagram of the equipment, the principle of its maintenance.

Installation of a pressure or non-pressure system can be carried out even by a master without experience.