Often, the ventilation system works inefficiently and part of the air penetrates from the ventilation duct back into the apartment. Especially noticeable is the effect of back draft ventilation happens in kitchens or in bathrooms of apartments. Check valves will help fight off odors.

The principle of operation of the ventilation check valve

Check valves in ventilation call a group of protective devices to prevent rotation of the air flow in exhaust ventilation systems or simply reverse draft ventilation in apartments. The valve passes air in the right direction, slowing down the reverse movement. Check valves for exhaust ventilation work automatically and this is the main plus of their use. In ventilation systems of residential and public buildings, non-return valves are used to prevent air from entering the common ventilation duct into separate rooms.

Check valves for exhaust ventilation work in systems with natural and mechanical traction. The valve prevents the penetration of insects and dust into domestic ventilation.

If you do not equip the system with a check valve, drafts may occur.

Types of Vent Check Valves

The main structural part of any non-return valve for natural ventilation is the shutter. It is he who does not pass air in an undesirable direction.

There are two types of round and rectangular check valves for ventilation:

- with a shutter in the shape of a spool;

- with a shutter in the form of a disk or slam.

The former are used for working with liquid media. The second ones are specially designed for ventilation. They happen with a horizontal axis of rotation or vertical, as well as single-leaf and bivalve.

Check valves for ventilation are made rectangular and round, with different cross-sectional diameters.

The main parameter when choosing a check valve is its throughput.

Natural-type check valves for ventilation are easy to manufacture and very reliable.

They are made of plastic or metal, the material is selected depending on the characteristics of the system. In vertical pipelines, the air flow moves vertically, so the valve is mounted horizontally, which ensures the correct operation of the shutter.

The most commonly used round and rectangular check valves with a throughput of 4 to 6 m / s. They work silently and efficiently. They are installed both independently and complete with an exhaust device.

All non-return valves for rectangular or round ventilation are also divided into:

- Warmed up. Such check valves for electric ventilation have the advantage of: condensation is not collected in the system, and the design will not be covered with ice in severe frosts;

- Without heating. Good for indoor use only.

The presence of an electric actuator at the check valve for ventilation requires the participation of an electrician in its connection.

Although the device is cheap, a non-return valve for ventilation can be assembled with your own hands, but more on that later.

Vent Check Valve Design

The check valve device is very simple: the disk-clap is attached to the axis, allowing it to swing freely. To close the valve while the fan stops, a plumb line is attached. Ventilation valves can be rectangular, round or square.

Industrial models differ from non-return valves for household ventilation in diameter and material, they belong to the explosion-proof category, although the device is the same.

The diameter of a round or rectangular check valve for industrial ventilation can be from 125 to 1000 mm, they are installed in explosive industries.

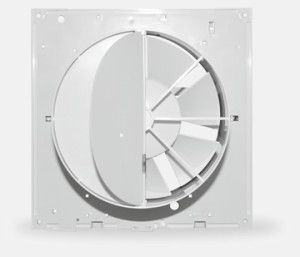

A butterfly valve model with two blades is widely used.

Butterfly devices are made more often from metal, the axis for mounting the blades is installed in the middle of the section. As soon as the fan stops, the blades cover the section and the ventilation back draft in the apartment stops. The diameters of double-leaf valves vary between 100 - 315 mm.

Improved modification of the "butterfly" is equipped with seals that reduce noise during operation of the blades.

Very often used for ventilation in the kitchen, a non-return valve in the form of blinds or petals (inertial grate). There are several blades in the structure, they are located on the horizontal axes.

How to choose a check valve

When purchasing a check valve for kitchen ventilation or to the bathroom, you need to take into account the speed of air movement, because the shutter must respond even to the slightest flow. Poor traction in the system is the main problem in organizing a natural ventilation system. Therefore, most owners combine a valve with an exhaust fan. To cover the structure from the side of the room, a beautiful ventilation grill is installed.

But for the natural ventilation system to work flawlessly, it is important to choose the correct check valve. Otherwise, the back draft in the ventilation of the apartment building will continue to poison the existence of residents.

Pay attention to:

- sectional shape;

- section diameter;

- valve material;

- valve device;

- purpose of the valve;

- manufacturing company (affects more on the price than on the quality of the simplest mechanism).

You can purchase a ready-made kit of a fan and a check valve. Here it is necessary to pay attention to the power of the fan. Suitable for the kitchen with a coefficient of 10, and for the bathroom and toilet will be enough 7.

When purchasing a check valve for household ventilation of a private house, it is important to consider climatic conditions. For example, a “butterfly” is faster covered with ice than a uniaxial design. In private houses, unlike apartment buildings, residents are not annoyed by the back draft in the apartment, but by blowing the wind into the ventilation and penetration of rodents into it.

Do-it-yourself check valve

Next, we describe how to make a check valve with your own hands. It not only effectively helps to avoid back draft in the ventilation of an apartment building, but also saves you money.

The installation of a do-it-yourself ventilation check valve is especially relevant for residents of the last floors of houses, where the problem of inhaling “alien” odors through the air ducts of the general exchange system is common.

We offer an improved model of the electric non-return ventilation valve with fan.

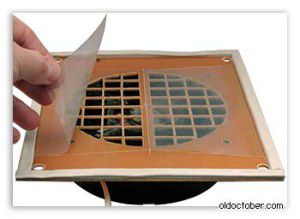

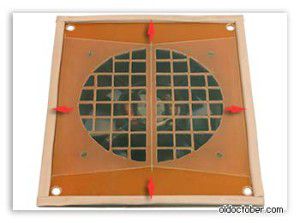

For the base of the check valve of the kitchen ventilation, thick plastic or textolite is suitable. You need a plate the size of which covers the outlet of the exhaust duct and a thickness of not more than 4 mm. Markings are made on the plate: a grill the size of a fan hole, as well as holes for wall mounting (at the corners) and for mounting a fan.

The larger the lattice cells, the denser the leaf material should be!

To prevent air from “walking” between the base and the fan, a rubber gasket is used.

To prevent not only the back draft in the ventilation of an apartment building, but also the penetration of insects, a small plastic net or even capron from tights is attached to the base grill.The latter is easily replaced. And so that residents are not bothered by vibration from the fan motor, shock absorbers made of rubber are used during installation.

Sashes are made of thick polyethylene (at least 0.1 mm). The film should be perfectly smooth, the smallest undulation will violate the tightness of ventilation, and the reverse draft in the apartment of an apartment building will resume. The sash can be mounted on tape with a fabric base. Detailed instructions for the manufacture of flaps for a plastic check valve ventilation in the video:

We recommend cutting the sashes in place, from an already glued piece of film. Moreover, if she is slightly wrinkled during operation, it must be changed. Two wings are cut among themselves only at the very end of the process. You need to cut with a sharp construction blade.

To prevent a gap between the homemade plastic check valve for ventilation and the wall, use self-adhesive foam tape.

During operation, it is necessary to periodically clean or change the plastic mesh clogged with dust.

With the right manufacture, such a home-made plastic check valve for ventilation will last for more than one year. And the residents of the apartment will get rid of the back draft characteristic for ventilation of apartment buildings for a long time.