The room for the gas boiler must be supplied with fresh air in accordance with state standards and SNiP. The requirements for ventilation in a private house are met by consumers so that the accumulation of by-products does not cause a fire and explosion. Inhalation of the substance harms the human body, so the supply and exhaust ventilation ducts must be provided at the design stage of the heating system.

The need for ventilation in a private house

Wall-mounted units of various capacities are used, having a compact and productive firebox of open or closed type. Less severe conditions are presented for equipment placement than for floor types, therefore they are placed in a boiler room, kitchen, bathroom or utility rooms.

Owners sometimes doubt the need for a hood in the boiler room, considering it sufficient to open the transom. It is inconvenient to keep the window open constantly in winter, and periodic ventilation does not completely solve the problem of air exchange. Forced air supply is organized, in addition to the natural flow. In the absence of normal ventilation, the productivity of the wall-mounted boiler decreases, and a normal air flow ensures the combustion of fuel without residues, therefore, the efficiency indicator increases.

The system performs the functions of:

- supplies oxygen in the volume that is needed for gas combustion;

- the hood removes smoke and carbon monoxide;

- removes accidental gas emissions causing poisoning of pets and humans.

The lack of fresh air reduces heat loss, provides incomplete combustion. Inadequate intake leads to the deposition of soot on the walls of the chimney, which reduces the clearance and reduces traction. The system protects against negative consequences if it is designed in accordance with the requirements of sanitary and technical standards.

Types of systems

The air exchange parameters depend on the capacity of the boiler, its operating features. The efficiency of the ventilation duct is affected by the area of the room and the frequency of use of heating equipment. The functionality of the hood is determined by the number of door and window openings and the climate of the area.

Ventilation systems vary:

- by the principle of obtaining traction there are natural and forced;

- at the rate of air supply - supply, exhaust, combined;

- the structure is canal or without channels.

Air is supplied from the street, from the next room through the aisles in the wall or through openings and structural gaps at the bottom of the door leaf. For every 1 kilowatt of boiler power, at least 8 cm2 of air from the street should be provided, and at least 30 cm2 should be supplied from the next room, based on a similar indicator.

Natural and mechanical

Unobstructed movement is provided by the difference in air pressure indoors and outdoors. The natural exchange of air masses occurs through cracks in windows, doors and when opening paintings and sashes. Air exchange refers to the organized type, if mounted or internal channels are arranged for movement, the flow of which is regulated.

The natural scheme works with a small capacity of the equipment and subject to the requirements for the hood for a gas boiler in a private house. The system is not very productive, suitable for houses with an area of 50 - 70 m2. Properly calculated ventilation updates the entire volume of air in the boiler room, while the outlet and inlet openings are located on opposite walls. As a flow inlet, a door can be considered, in front of which a boiler is placed. Windows with this placement can be on any wall.

If it is impossible to ensure a natural intake of air, resort to a mechanical circuit. In this case, the pressure difference is created by electrical appliances. Efficient delivery is combined with dust removal, increased humidity and temperature.

Used equipment:

- fans

- silencers;

- electric motors;

- traps of impurities.

Forced systems move flows in the required volume; their efficiency does not depend on climate. Equipment changes air parameters, which cannot be done with a natural scheme. If the room is completely sealed from drafts, when the hood with the column, convector and boiler is at the same time, the draft may tip over and carbon monoxide will be drawn into the room.

Exhaust, supply and combined

The air handling unit is mounted in the fresh air ventilation duct. Electric fans provide a constant flow for combustion, which is important for boilers with an open chamber, which use the surrounding atmosphere. A filter is placed in this channel to clean the outside air. A monoblock circuit with a common housing works efficiently where the required elements are arranged.

Exhaust ventilation uses the power of a blade device, which is placed in the removal channel. In this case, air is drawn in through an organized supply passage. The exhaust system reduces the carbon dioxide content in the atmosphere of the boiler room not only with a hinged boiler, but also with a floor-mounted, or in a boiler room with a solid fuel unit.

Combined smoke removal and oxygen delivery systems are optimal solutions. Compressors and condensers are used, fans are installed in the supply and exhaust pipes. Two flows interact in the system, which differ in their purpose and chemical composition. The combined model for air exchange can use any number of rooms in the building.

The first stage involves the intake of air from the outside and the exhaust of the exhaust smoke, while the incoming and exhaust stream is cleaned. Factory-made supply valves are equipped with a grid, grille, and hatch. The exit hatch is not placed next to the heating unit, as cold air in winter can reduce the efficiency of the boiler.

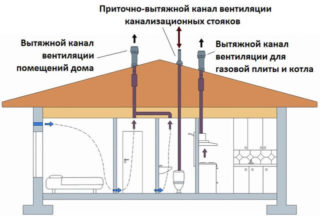

In the kitchen, the exhaust pipe is discharged into the ventilation shaft in a standard way and passes through the attic to the roof. Combined systems include a coaxial chimney, in which smoke is removed in one pipe and oxygen is supplied.

Channel or non-channel

The channelless view effectively functions in boiler rooms of a small area. Such a system is installed when placing a wall-mounted gas boiler in an apartment, garage, warehouse. The monoblock is placed on the roof, above the installation area of the unit, placed in the wall, displayed in a window or under a door.

Air is supplied:

- outside;

- from the subfloor;

- from under the ceiling space.

The channel-free system requires a little electricity (if combined with ventilation), differs in simple installation and is inexpensive. Ventilation without channels can be natural, mechanical, exhaust and supply.

Channel ventilation of the boiler room is difficult, but it works more productively.Models are selected by power depending on the parameters of the boiler and application conditions. Ducts are round, square, rectangular, different sizes and diameters. Communications are located hidden in the walls, behind the protruding structures, or hanging boxes and pipes are used at a height.

Principle of operation

The equipment is an exhaust or supply ventilation unit for processing air flows and supplying it to the boiler room. The unit is a component of a heating system and is often connected to a central pipe. Air flows directly from the street or through the air duct. A complex system consists of metal boxes or pipes between which functional devices are mounted. External elements are protected from atmospheric action.

Working elements of the system:

- A fan with a two-phase electric motor delivers air to the boiler room or to the common air duct.

- Filters purify the air, using coarse species or an electrostatic precipitation method. Coarse elements are placed in front of thin filters, protect them from breakage and are easily replaced.

- Heating or cooling equipment changes the temperature of the incoming stream. Heat pumps, electric heaters or evaporators are used.

Balancing devices, shock absorption and sound insulation in the system eliminate vibration and reduce sound during operation. Oscillations are isolated and damped by obstacles, and the fan is placed on supports from springs.

Ventilation requirements in a private house with a wall-mounted gas boiler

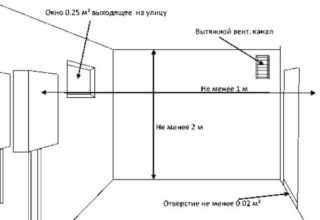

The rules for selecting and installing a ventilation system are contained in SNiP 2.04.05 - 1991. Attention is paid to air exchange, which should occur at least 3 times per hour. For a natural influx, a window must be made in the window opening, and there must be a gap of about 2 cm under the door or holes are drilled at the bottom of the canvas.

Requirements for ventilation in a gas boiler:

- smoke is removed and fresh air is supplied through isolated channels so that oxygen does not come into contact with the combustion products;

- the area of the window for supplying outdoor air should not be less than 1/30 of the floor area of the boiler room;

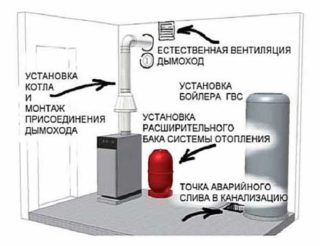

- a wall-mounted boiler is mounted next to the outlet of the smoke channel and ventilation shaft;

- if a coaxial pipe system is installed, an outlet is made and a technical one is used to repair and clean the chimney.

In a private house, ventilation in the boiler room should always be with open hatches so that air exchange is constant. Gas workers, before starting heating, check the laying of the sewer, water supply, heating and the compliance of these systems with the norm. The gas outlet must be insulated, the ceiling height should not be lower than 2.2 m.

Ventilation system device

For a heating unit with a closed furnace, a coaxial chimney is optimal, which contains two isolated channels in one pipe. The inner pipe serves to remove combustion products, and oxygen flows through the outer chamber.

When ventilating, observe the rules:

- no more than two types of gas equipment are connected to the chimney;

- the ventilation shaft is tightly insulated;

- the supply and exhaust system is made of materials that do not burn;

- the cleaning channel is made 25 cm below the main one;

- from a horizontal smoke exhaust pipe to the ceiling should be at least 20 cm;

- the exhaust outlet is isolated from the cold by heat-resistant materials.

For a wall-mounted boiler with an open firebox, separate air supply and smoke pipes are arranged, with openings provided opposite each other. The system is equipped with a non-return valve to prevent tipping of the rod.

Ventilation installation

Ventshacht openings are closed with metal or plastic grilles, decorative elements are fastened with dowels. The blade or axial fan is mounted in the hole using self-tapping screws. Before facing the tiles on the walls, wiring of the supply wires is done so as not to lay them on the finish. If the fan will work periodically, a switch is set to start it, a special time timer can be used.

To pass the pipe in the wall, a hole is made with a slight slope (condensation draining) to the outside of the wall. The brick is drilled with a drill, and the concrete is broken with a punch or a chipper. The duct is inserted and insulated with heat-resistant material (mineral wool or foam for installation work). On the outside is placed a ventilation grill.

Organization of outflow and air inflow

The diameter of the pipe is determined by the power of the boiler. With a 30 kW boiler, a size of no more than 20 cm is provided. Too high or low location of the holes leads to a slowdown in air exchange. If the chimney exit is located below the roof ridge, a cold stream will flow through the outlet, and the combustion products will not be removed.

The chimney can be equipped with:

- horizontally;

- with rise and bend;

- vertically to the ceiling with a bend;

- vertically directly through the roof.

The yellow flame of the burner and a large volume of soot indicates an insufficient oxygen level, so you need to use a fan for the supply system.