The node of the passage of ventilation through the roof is the most important structural element, manufactured in compliance with the requirements of building standards. A competent approach to its arrangement guarantees the integrity of the roofing (its tightness). To understand the installation features of this element, you will need to familiarize yourself with the types of output nodes and their markings.

Passage Node Requirements

According to the requirements of the standards, the passage through the roof for ventilation is done in such a way as not to reduce the level of tightness of the existing coating and to prevent moisture from entering the building. It should also not interfere with the natural runoff of sediments and should have reliable thermal insulation protection. In the upper part, the chimney pipe is closed with a special visor (deflector), which protects it from moisture entering the inside.

With a forced air exchange system, an exhaust fan is installed next to the unit, which needs to be isolated from precipitation and moisture. In addition, reliable grounding of the electrical unit will be required. When installing a typical passage unit (UP), additional elements are used that protect the structure from precipitation and contribute to the removal of moisture. The most rational is the location “along the slope”, in which there is no interference with the runoff of water, or along the ridge. The latter method allows you to do without additional elements that reduce resistance. A typical error during the installation of the ventilation unit is to introduce a sealing element (front apron part) under the cover sheets. Water flows into the resulting gap, which then penetrates the roofing cake and seeps into the attic.

Varieties of UP

In the free sale there are nodes of passage through the roof for air ducts, made in square or round section. They have a special mounting washer; they are equipped with stiffeners to strengthen the structure. Such modules are intended for installation in support cups made of reinforced concrete, fixed on the floor slab during the construction of the house. The latter has a horizontal platform, the design of which allows you to mount UP on the slopes of almost any steepness.

By design features, several types of passing nodes are distinguished:

- with condensate ring and without it;

- without valve;

- with manually operated valve;

- with electric actuated valve.

Valves are needed to block access to cold air when the system is off.

Ventilation units are available that have additional insulation. According to the shape of the channel, UEs are round, as well as square or flat (rectangular).

Marking and fasteners

Various passage elements are marked according to the system below:

- Designation UP1 with a digital index from 01 to 10 refers to products without a valve and a condenser ring (they differ in their diameter).

- The UP2 letter indices with numbers from 01 to 10 mark devices with a manually controlled valve and without a ring.

- The designation UP2 with numbers from 11 to 21 is assigned to valve mechanisms with a capacitor ring.

- The name UP3 is assigned to elements equipped with a special platform for the valve.

Type designation “UPZ-21”, for example, is deciphered as follows: valve assembly, designed for manual control and having a ring for condensate drain ..

Features of self-assembly

The set of modules for penetrating through the roof for ventilation includes hardware and embedded parts that allow them to be fixed to wooden elements, reinforced concrete glasses. The function of thermal insulation protection is performed by mineral wool covered with a layer of fiberglass. When installing modules with a protective valve, the pipe designed specifically for it is taken into account. The valve mechanism is attached to the lower edge of the tubular element. Its upper flange serves to ensure a fixed position of ducts or pipes. For fasteners, the supplied clamps and brackets are used.

Before choosing a passage node, the slope of the pitched roof, as well as the distance from it to the ridge of the roof, are taken into account. It is also important to determine the option for the presence of a valve and a ring. All of these options vary depending on operating conditions. There is no need to install a mechanical valve, for example, when the system is already working normally and does not require constant adjustment.

UP are made of the following materials:

- polymers of various classes;

- stainless steel 0.5-0.8 mm thick;

- black steel 1.5-2 mm.

A specific sample is selected depending on the type of roofing material used and the characteristics of the outlet pipe. Despite the fact that the imported units are distinguished by high quality workmanship, they do not always suit local conditions. Preference is therefore often given to domestic parts.

Work

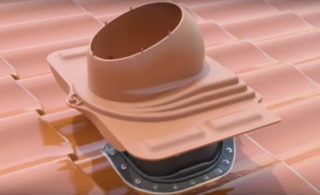

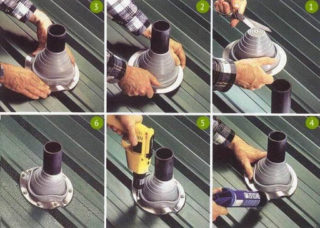

When arranging a unitary installation, attention is drawn to two methods of their installation, differing in the type of roof - hard and soft. In the first case, the structural units are mounted on the roof of tiles, slate or corrugated board. For their installation, a square seat is prepared, the cracks around which are filled with a heat-insulating compound. Flanging is performed on top of it to protect the thermal insulation from moisture accidentally entering the pipe hole. Four apron elements are mounted around the sleeve, covering the areas where the pipe adjoins the roof on all sides.

When installing the structural element, the lower part along the ramp is first attached, then the side ones. After their fixation, the upper sector of the apron is placed, the horizontal parts of which are wound directly under the roofing. The sides and the lower part are located on top of the roof. Often, another element (tie) is used - an elongated gutter provided in the roof construction kit. But most often it is possible to do without it; to clarify its need, it is better to consult with specialists.

The apron is sold as a finished part, but if desired, it is easy to make it on your own. For this, a galvanized sheet with a thickness of 0.5 mm is suitable. Thicker workpieces are not used, since it will be difficult to give them the desired shape.

Designs designed for soft roofing differ in the general order of installation of the components of the ventilation passage. Slopes on roofs with such a coating, as a rule, are carried out with a slope of 12º or more, which forces us to select the required sample with special care. The arrangement of UP in a pitched roof with a soft coating is calculated in advance, which allows you to choose the best installation option.