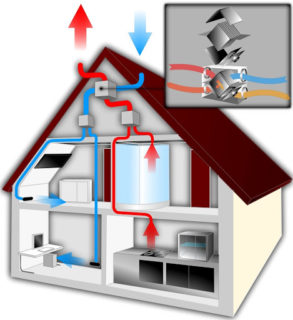

An air recuperator for the home is an integral part of the ventilation and air conditioning systems. This device helps to create a comfortable indoor microclimate, as well as significantly reduce heating costs. Before buying a recuperator, you should learn more about its purpose and principle of operation, pluses and minuses, selection rules and available varieties.

What is a recuperator

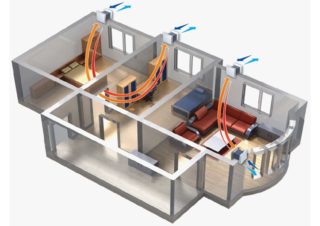

The recuperator for the home is a heat exchanger having a special design, used to ventilate the premises. Its main task is to transfer thermal energy from the exhaust air stream to the supply stream supplied into the room. Such energy means both thermal and refrigerating, therefore, the exhaust stream is capable of delivering both heat and cold to the supply air, warming it alternately or cooling it. A recuperator is needed to pump stable energy from the air leaving the room. During its operation, the air flows are not mixed, so the supply air is not polluted by exhaust.

The device can generate good energy in both winter and summer. In winter, the recuperator must heat the supply stream using exhaust air. For this purpose, the cool air stream outside and the warm stream from the room go inside the heat exchanger, where the exhaust air warms up the supply air. This heating helps to save the power of an electric or water heater in ventilation installations. The presence of a recuperator also makes it possible not to lose most of the heat during ventilation and to reduce the heating load in winter.

If the supply air stream warms up to +10 degrees due to exhaust, the heating power in this situation is calculated at 8 degrees taking into account heating. Since it corresponds to the temperature difference, the presence of a recuperator in this case would make it possible to save 82% of the system capacity for ventilation.

Varieties and features of recuperators for a private house

A standard recuperator for a private house consists of a base with nozzles, mounted fans, heat exchangers and filters. If it contains a single heat exchanger, the supply and exhaust air inside will exchange heat through thin walls. In the presence of a double heat exchanger in the first exhaust stream gives energy to the intermediate carrier, in the second - the intermediate transfers it to the supply. To choose the suitable option, you need to know by what principle each of the four types of devices works.

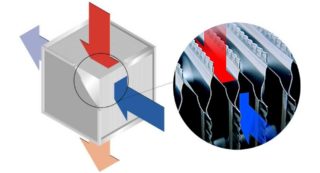

Lamellar

Plate devices are used in supply and exhaust systems of a monoblock type. These are devices based on a plate heat exchanger without moving parts, air moves along its channels during operation, flows alternate between each other. The output and input streams are fenced with plates of their aluminum, through which heating is carried out. Such devices are designed to maximize the area of contact with the flows. It is due to this that the efficiency of heat transfer and heat recovery in them is at a high level.

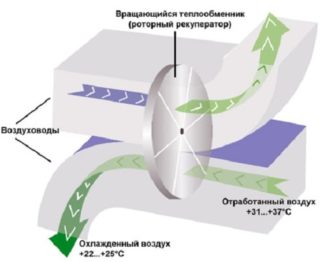

Rotary

Rotary devices are considered the most effective in comparison with analogues.Their design is a wheel or rotor, the rotational axis of which corresponds to the movement of air along the lines. Half of such a wheel is located in the exhaust flow section, and the second half is in the supply air region. The rotor itself consists of plates bonded to each other, through them air passes freely during operation. The rotary air recuperator first comes into contact with the exhaust stream heating the wheel. After its part enters the supply air area, there it heats up and transfers the received heat. Then the part of the wheel is again in the exhaust air zone, the cycle is closed.

In the process of transition of the wheel from the region of the exhaust flow to the supply air part, a small amount of air enters the rotor. This becomes a cause of mixing flows, but such a problem is practically absent in more expensive and modern devices.

Water

Conventional water air recuperator suitable for a private house, runs on water used for the purpose of heat transfer. The principle of its operation can be compared with the operation of the boiler, replaced by a heat exchanger and built into the hood. The radiator in this device is a special element designed for incoming flow from the outside. Water is heated in a heat exchanger and gives off heat in an additional element. Such recuperators are considered insufficiently energy efficient, but at the same time they are cheaper than powerful analogues and work according to a simple scheme.

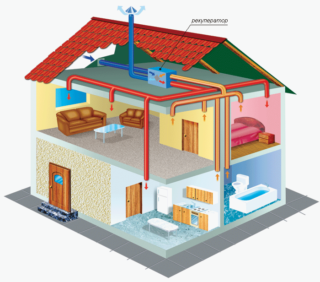

For the roof

Ventilation devices for roofs are used to filter, heat and supply air into the object. The temperature of the air flows in them is regulated by a cooling element or a channel heater. The air flow passes partially or completely through the plate of the device. Such systems are installed on the roof ceilings using the holes made in the roofs. Recuperators of this type help to recycle the processed air collected under the ceiling and push it into the atmosphere, transferring heat to the incoming stream. Air is supplied to the ceiling or directed to the main zone.

The device for the roof can also be part of the general ventilation scheme, in such situations it is indicated in the drawings. This device is easy to maintain and is available in several versions. They vary in power and are measured by the volume of air passing through them. The device is based on a frame-panel type construction made of aluminum profiles with sheet thicknesses up to 0.2 mm. The walls of its base are supplemented with mineral wool for insulation, also such recuperators are equipped with water, gas and electric sections.

Advantages and disadvantages

Before installing a recovery system, it is useful to familiarize yourself with the pros and cons of such devices in advance. Their benefits include:

- the ability to completely replace the natural ventilation process;

- the device is cleaned using filters in a closed form, this method protects the recuperator from pollution;

- the opportunity to reduce the cost of electricity, heating and additional systems by 30-50%;

- quick removal of excess moisture, odors and harmful substances thanks to a permanent working ventilation system.

Of the minuses of devices of this type, the presence of noise during operation is noted, the need to clean the channels after prolonged use, periodic power failures, after which the system will not start automatically, as well as costs at the initial stage of operation.

Recuperator selection rules

To choose a good recuperator, you need to consider several important factors. The local climate is taken into account, as this is of great importance for some types of instruments, for example plate ones. For the home, it is advisable to choose the least energy-consuming model, so when choosing pay attention to the power of the unit. Additionally, the area of the filtration material is taken into account, if it is large, the service life will significantly increase, and the cost of electricity will be reduced.

It is better to purchase devices with high-quality filters, the simplest ones can remove only large particles of dirt, more complex ones trap dust, including fine dust. It is necessary to take into account the performance of the recuperator, which should correspond to the size and needs of the room. The intensity can be affected by the amount or frequency of replacement of air flows. In terms of control, it is worth choosing devices with an automation system that provides more features.

DIY installation and manufacturing

Installation of any recuperator does not cause difficulties, if performed according to the rules. At the stage of installation and connection to the system, the device must be fixed on a solid surface and docked to one exhaust and supply duct. Next, the connection sections are treated with a hermetic composition and the recuperator is placed in a heat-shielding and noise-insulating case. If the installation of the device is provided for as part of the ventilation system project, this procedure should be entrusted to a specialist.

Duct recuperators require the installation of two air ducts in each room in order to supply and intake air flows. At the same time, the living cross-section of the gratings is calculated and the sockets are properly selected to eliminate unnecessary noise.

If necessary, the recuperator can be made with your own hands, in this case the plate type system will be the best choice. It has a good real level of efficiency, a simple and reliable design, and also does not require attachment to electricity.

Scope of the recuperator

Installation of a recuperator in any house is necessary if its owners plan to create an optimal warm system with a fan, heating and air conditioning. The choice of a specific type of device depends on the needs, most often used plate or rotary units.

Lamellar devices are easy to install and maintain, low cost and power, and they also have low efficiency. They are ineffective in heat exchange systems for large areas and are not suitable for rooms with high humidity levels. It is advisable to use them to create ventilation systems in country houses, on individual housing construction objects, in office or administrative buildings, industrial areas and warehouses.

Rotary devices have good power, have a high level of efficiency, do not depend on operating conditions. At the same time, they need quality service and regular technical inspection. Such devices are ideal for large workshops, large residential or administrative buildings and buildings, rooms with high humidity and too dry air.