The installation of double-glazed windows was not provided for in the construction of houses with wooden windows. Fresh air entered the room through the cracks. Modern metal-plastic window constructions do not allow air to pass through, so air exchange is disturbed, ventilation after installation of new windows is often absent. To solve this issue, a supply valve was invented. It is necessary for the influx of fresh air. At the same time, the ventilator prevents significant heat loss and noise from entering the room.

Feasibility of using a supply valve

The air in the room, according to sanitary standards, must be constantly replaced: dirty - removed through the hood, and fresh - come through specially made openings. Then the residents will not experience breathing problems, humidity, and often get sick. In houses with traditional window frames, the installation of supply air holes was not required, because the air passed through the cracks. In sealed metal-plastic constructions, a sealant is installed that protects from noise, retains heat, but at the same time interferes with the normal functioning of the ventilation system.

Fresh air masses come in with simple ventilation, however, this method has several disadvantages:

- when the window is closed, ventilation is not carried out;

- if it’s cold outside, when airing out of the apartment heat leaves;

- the supply air volume cannot be controlled in any way - the flow is uneven, drafts arise.

Manufacturers are aware of the drawback and make fittings that solve this problem - inlet valves.

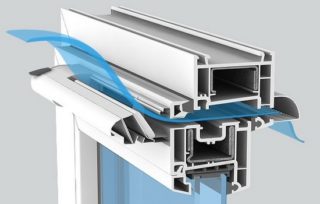

Device and principle of operation

The ventilator works due to differential pressure, natural draft. Therefore, exhaust ventilation must be operational, otherwise installing a supply valve on a plastic window will not bring significant benefits.

The valve consists of the following elements:

- air intake - located from the street, protected from insects and rain by structural elements;

- channel - a tube installed in the hole of the window frame manufactured during installation; air enters through this channel;

- exhaust block - an element from the side of the room, equipped with a filter, nozzle and control valve.

Under the influence of natural traction, fresh air mass enters through the hole in the frame. The cold stream collides with the ascending air mass from the heating system located under the window, under the influence of heat rises to the ceiling and mixes.

The supply valve only works optimally at temperatures below + 5 ° C.

Varieties of supply valves

Ventilators differ among themselves by production material, quality, throughput characteristics, features of functioning and installation.

According to the material of manufacture, valves are distinguished from metal, wood, plastic.

By the method of inflow emit:

- Folded ventilators - their installation in the frame is carried out by cutting holes. The double-glazed window at installation is not dismantled. The insulating properties of the window structure are preserved, installation does not cause special difficulties. However, the folding devices have low productivity - not more than 5 m3 / h. They are recommended to be installed in small areas or two ventilators per window at once.Some models are automated.

- Slotted air inlets - consist of one or two blocks. The length of the slit is from 17 to 40 cm, the width is from 12 to 16 mm, which ensures a sufficient inflow volume of about 20 m3 / h. To install two-block models, you will need to milling the window frame. A simple slotted inlet valve is installed in place of the seal part. The inlet cover protects against insects, dust, rainwater from entering the house. Indoors, an adjustment system is provided.

- Overhead ventilators have maximum performance compared to other window inlet valves. They can even be installed in blind window frames. However, the installation is done before installing the double-glazed window, or it will have to be changed. In addition, overhead models are not suitable for residential premises, because they significantly reduce thermal and sound insulation.

- Slotted valve

- Overhead valve

The air exchange rate is adjusted mechanically or automatically.

Installation on plastic windows

The seamed ventilator is installed in the upper part of the window, it is best to choose a warm season for this. For frame milling, electrical equipment and other tools will be required:

- jigsaw;

- electric drill with drills with a diameter of 5 and 10 mm;

- template from plywood or hardboard;

- fine-grained file;

- silicone sealant.

At the preparatory stage, the sash is removed, installed in an inclined or vertical position, the fittings and reciprocal strips are removed, which will interfere with milling.

Installation step by step:

- Make markings by putting a template on a vertical ledge.

- A drill with a diameter of 10 mm is drilled into a series of several holes at a certain distance from each other.

- Jigsaw connect the holes.

- Repeat the procedure on the surfacing of the frame.

- The opened window chambers are filled with sealant.

- The mounting strip is treated with a sealant on the back side and applied to the sash. Fix it with screws.

- The indoor unit is latched onto the bar.

- The external visor is fixed with screws. Compounds are treated with sealant.

- Mount the window fittings and sash back.

Drilling and cutting must be done carefully so as not to damage the window.

A valve that does not require milling is even easier to install. Need tools:

- centimeter;

- construction knife;

- a screwdriver or its electrical equivalent is a screwdriver.

The complete set of the supply valve of this model includes:

- set of sealing tapes;

- stubs;

- self-tapping screws;

- directly valve itself.

If the sash is wide enough, the valve is placed in the middle. If narrow, they are shifted left or right so that window fittings do not interfere.

Mounting the valve for fresh air ventilation on the window is as follows:

- Mark out the installation location. Notches are made at the extreme points and the sealing tape is removed.

- Fixing dowels are installed in the freed groove: two at the edges, one in the center.

- Remove the protective strip from the adhesive tape and glue the valve.

- Fix the device to the window profile with screws, screwing them into the dowels.

- The ribbon on the frame is changed to a narrower one from the set.

After installation, adjustments are made by changing the position of the slider left or right. The right position increases the flow of air, the left - reduces.

After installing the ventilator, the ventilation in the apartment should be adjusted. If this does not happen, there are more serious problems.

Adjustment and operation

The inlet performance depends not only on the channel cross-section and the pressure difference. Optimum performance is 20-35 m3 / h with a static pressure of 10 Pa.In the technical documentation attached to the ventilator, the performance is indicated taking into account the standard pressure difference. Sound insulation performance should correspond to similar parameters of a metal-plastic window. 30-35 dB is the preferred range. In this case, sound insulation after installing the valve will not be affected. The best in the conditions of the domestic climate are those with a thermal break.

Supply air volume adjustment is not available on all models of ventilation valves. Where possible, tuning can be automatic or manual. In the simplest devices, the ventilation intensity is not regulated in any way.

An automatic valve operates according to one of two principles:

- The air supply is stabilized due to the difference in street and internal pressure. The predetermined inflow range is preset and this volume is automatically maintained.

- A polyamide sensor is used. With its help, the valve cross section is regulated: it increases with excess moisture and decreases when the indicators are normal.

Automatic devices are more expensive than mechanical ones; airing lock is available only in some models.

With a manual setting method, airing is carried out at the request of the owner and with the intensity that he chooses. The disadvantages are that mechanical devices require constant monitoring and there is a risk of overcooling the room and the occurrence of drafts. Usually the extreme left position of the regulator indicates a fully open ventilation hole, the extreme right position that the hole is closed.

Features of operation of supply valves:

- Do not completely close the valve in frost. If necessary, it is necessary to partially seal the external gap in order to reduce the intensity of air intake.

- Twice a year, the external visor is cleaned with a vacuum cleaner, and the body is wiped with a damp cloth.

- Do not use harsh chemicals to clean.

- Air filters should be changed periodically.

- During repair work, the valve is protected from dust.

For residential premises, it is better to choose devices that allow you to control the intensity of air exchange and completely block it.

Overview of the best manufacturers

Supply valve models are available in different countries and are available in technical and color variations.

Aereco - manufacturer of ventilation valves for plastic windows from France. The assortment includes products with enhanced sound insulation (EHA2 series). There are valves in the line with a V8 sensor, which automatically regulates the air flow taking into account the level of humidity. The color of the valve can be matched to the shade of the window. Ventilators are available in gray and white, in teak and beech. Particularly popular models:

- ЕНА2 - plastic devices with a capacity up to 35 m3 / h. Three varieties are presented with different throughputs. Sound insulation at 37 dB.

- EMM - feature a movable outdoor unit.

- EMF - with mechanical adjustment.

Air box - A domestic manufacturer producing mechanical type valves from plastic. There is no humidity level sensor in them, but its absence is compensated by the ease of installation, attractive cost. The outdoor unit is also missing. The inlet is fixed on the casement inside.

The lineup is represented by the series:

- Standart. Milling is not required. Productivity is small - 4.8 m3 / h. Sound insulation level - 32 dB.

- Comfort. It is installed with and without milling. When installing the first method, the productivity increases to 42 m3 / h against 31 m3 / h. Can be installed on any sash.

- Comfort S. Productivity - from 40 to 42 m3 / h. Installation is carried out with milling.The main difference is the two-way flow direction, which increases the efficiency of ventilation.

Rehau - one of the most famous manufacturers, proven with the best hand. It produces several series of products, each of which is designed for premises for various purposes:

- Aerovent + - for city apartments. Valves are characterized by simple installation, a sufficient amount of air exchange.

- AR75 - a line for country houses and spacious apartments. The valves are designed to ventilate several rooms, provided that the glass is replaced, they are installed in the finished window. Thanks to the multi-stage adjustment system, the maximum inflow volume is up to 113 m3 / h.

- Invisivent - for large public areas. The supply air volume reaches 300 m3 / h, while the valves are distinguished by improved sound insulation and easy maintenance.

Reenson - Belgian manufacturer of slotted aluminum ventilators. Aerovent model stands out, which has a capacity of 21 m3 / h (for a difference of external and internal pressure of 10 Pa). Noise isolation is at least 42 dB. A safety net and a filter are provided.

Qualitative and diverse products are produced by firms: Helios, Siegenia, Mabitek. They deserve the trust of customers.

Supply valves are a technologically advanced and convenient ventilation replacement. They are installed where there are children, because they protect against drafts and cold air creeping along the floor. Ventilation valves work as ventilators, and not as air conditioning systems, so they do not replace specialized equipment.