Improper organization of the chimney for a gas water heater leads to increased fire hazard, harm to life and health of people. A properly selected and installed chimney will protect the residents of the room from the danger of fumes and fire. You should consider the structure of the chimney in detail, understand the selection criteria, the subtleties of installation.

Chimney system

In a multi-storey building, a sealed channel connects the combustion chamber of the furnace and the ventilation pipe. In a private house, a mine or pipe goes directly to the street. In the same way, the hood for the geyser is installed when installing autonomous heating by a gas boiler.

Chimney components:

- receiving branch pipe connected to the combustion chamber;

- line for the removal of gases of a certain length and configuration;

- swivel fittings of the outlet channel;

- condensate collection tank (glass);

- passage elements;

- fungus ventilation.

Highways are made with and without insulation, depending on the needs and characteristics of the building. Warm combustion products naturally rise up and are removed from the room. The specific gravity of hot carbon monoxide is higher than air density. The thrust is greater, the higher the exit point of the outlet pipe. If possible, the hood is raised as high as possible with a minimum number of turns of the exhaust channel.

Varieties of chimneys

Chimneys are divided by location and by production materials. At the place of position - internal and external.

Mounted indoors - indoor. Its walls are not exposed to the negative influence of external factors - rain, negative temperatures, ultraviolet light, and temperature changes. This design is more durable. The increased heat transfer is used for additional heating of rooms.

The minus of the inner pipes is:

- danger of leakage of harmful gases during depressurization;

- the possibility of fire with improper thermal insulation;

- the need for additional thermal insulation when passing through floors;

- the chimney pipe occupies a certain place in the room and its presence sharply limits the usable area.

The construction of the internal chimney is associated with additional costs for coupling structures, thermal protection.

External chimneys are discharged through the wall of the house and go outdoors. They have many advantages:

- simplicity of construction and the possibility of integration without affecting the decoration of the house;

- price;

- ease of repair and preventative maintenance;

- safety against leakage of harmful gases.

Along with the advantages, there are a number of disadvantages:

- need to be insulated to reduce the formation of condensate inside the pipe;

- negative environmental impact;

- cannot be used for additional room heating.

The material of manufacture of the internal chimney shafts and external is different.

Steel chimney

The ventilation duct made of steel pipe is the most practical. The round section gives the maximum flow rate. Ideally, the pipe should be made of stainless material. The stainless steel is resistant to acids and condensate. It is not necessary to brick it. The ferrous metal pipe is lined with refractory bricks, reducing the impact of harmful factors.

Stainless steel is sometimes enameled on the outside. The pipe looks much more aesthetically pleasing. The steel structure is easily placed outside the house. The foundation for the support is not needed.

Need fire cutting when passing through walls and partitions. It is necessary to strictly comply with SNIP requirements for the location of the chimney structures. A condensate collection pocket is located below the structure. Allowed the presence of one horizontal section of not more than 1 pm Elements are connected to each other with clamps or shaped joints. According to SNIP, the depth of the pipe nozzle should be not less than the radius.

Double Sandwich

The design of the sandwich pipe is 2 pipes of different diameters with heat-resistant insulation inside. Equally suitable for indoor and outdoor use. By execution, they are divided into 2 types:

- both stainless steel pipes;

- the inner pipe is stainless; the outer one is galvanized.

The types of stainless steel used vary. The most resistant to external influences brands: AISI 430 and AISI 304. Only for external shells. For internal and external pipes: AISI 316i, AISI 321, AISI 310S. A bona fide manufacturer always indicates the grade of steel. The final price of the pipe can vary greatly.

Brick, asbestos-cement, ceramic mines

The ideal sectional duct is a circle. The gas velocity in this section is maximum. However, laying bricks around the round is unprofitable and inconvenient. Moreover, the high temperature of the gases requires laying the channel out of refractory bricks, which is not cheap. But this does not save him from fouling with soot inside. The process of laying out the chimney for the column is extremely time-consuming. It is necessary to combine heat-resistant materials and binders correctly. Laying out is easier with experience, but even knowledge of the masonry technology will allow you to control the quality of the contractor. To ensure sufficient traction, ventilation must be raised above the ridge of the roof, depending on the location of the pipe. The closer to the edge of the house, the larger the takeaway. The maximum angle of decline between the tip of the pipe and the ridge is 10 degrees. But even with good traction, the brick is destroyed by exposure to acids, soot, and condensate.

The flue from ceramic pipes is a complex structure. Outside, the pipe is lined with lightweight foamy concrete, and the space around the ceramic is filled with insulating material. The length of ceramic elements is 0.2-0.6 m. On one side there is a bell into which the previous element is inserted. Compounds are sealed with acid resistant material. The thermal insulation must be heat-resistant, the remaining grooves in the blocks to be covered contribute to the ventilation of the insulation and soften the temperature expansion of the ceramic pipe. The constructive blocks for wrapping can be any depending on the number and size of pipes. Manufactures make ready-made pipe-block sets with all necessary fittings. The warranty period of these elements reaches 30 years.

Ceramic chimneys are carried out inside the premises. The outdoor arrangement requires reinforcement with bricks or concrete blocks.

Advantages of ceramics:

- the inner layer of the pipe is made of smooth heat-resistant glaze that prevents the deposition of soot;

- the gas velocity in ceramics is maximum;

- the waterproofness of the walls contributes to the condensate draining into a special pocket, so the pipes do not absorb moisture and do not collapse;

- soot is easily removed from the smooth walls of such pipes;

- ceramics are heat resistant, even if soot ignites, nothing terrible will happen;

- the ceramic pipe does not act with acids, does not absorb moisture, is resistant to other chemical elements;

- assembly of such a chimney does not require a special tool.

Along with the pros, there are also disadvantages:

- significant cost;

- heavy construction weight;

- obligatory foundation;

- mounting accuracy.

Corrugated aluminum foil or stainless steel leads

Aluminum or stainless sections are installed when cornering the gas outlet. Flexible corrugation is used to remove exhaust gases from the furnace of the column into the chimney of the apartment. Use on rotary sections, when leveling pipes in areas with low temperature. The best option would be thick stainless steel. Thin aluminum foil easily breaks and burns out quickly.

Proofs of the corrugation:

- ease of installation;

- simple bypass of some designs;

- bending at different angles;

- low cost.

Significant Cons:

- short service life;

- rapid pollution by combustion products.

Aluminum corrugation consists of wire and foil. 70 cm section is able to stretch up to 3 m, which is very convenient. Corrugated corrugation consists of metal with a thickness of 0.2-1 mm. The diameter is 110-130 mm.

Recommendations for the placement of a chimney for a gas column

The basis of the ban on the installation of the chimney can be an insufficient floor space. Lack of supply and exhaust are also an obstacle.

- Do not place speakers or chimneys in a residential or bathroom. The area of the bathroom is usually not more than 8 square meters. m

- Do not install in kitchens over hobs.

- Norms allowed the installation of equipment in the loggia and on the balcony.

- When operating in the kitchen, the ventilation grill should be located below.

- Flexible eyeliner to the column cannot exceed 2.5 m.

It is not recommended to hang the column on the wall adjacent to the living room. With a flexible gas supply distance of more than 2.5 m, the steel supply pipes are extended. Then a flexible sleeve is connected.

Chimney selection requirements

The choice of the chimney is based on the characteristics of the gas column. You need to know the smoke removal scheme, installation conditions, the diameter of the exhaust pipe, it is desirable to draw up a diagram indicating the dimensions and characteristics. These data will help in choosing the elements of the chimney, will allow you to get competent expert advice.

According to the SNIP, corrugated and other pipes for the output of burnt gases from the gas column must satisfy the conditions:

- minimum surface roughness - SP 60.13330.2012;

- B-class tightness;

- resistance to corrosion;

- have up to 3 turns;

- work in the temperature range 200-350 ° C;

- have no sagging;

- Do not go through housing.

The corrugation is located at a distance of 5 cm from the non-combustible wall or 25 cm from the combustible. The gap is clogged with non-combustible insulating material.

It is allowed to use roofing or galvanized steel from 1 mm in materials, flexible corrugated tubes, universal materials supplied with the product.

The roughness of the inner wall is allowed no more than 1 mm. The outdoor is not standardized. The exhaust material must be resistant to corrosion, acid compounds.

Despite the requirements of SNiPs, it is corrugated compounds that are popular because of their convenience. They can be hidden, hidden in cabinets, covering all this with removable panels.

The ideal material is stainless steel. Durability, smoothness, esthetics - these parameters are the most successful.

Installation of a chimney for a geyser

Installation of the column in the kitchen begins with measurements and preparation of the necessary materials. The corrugated transition is easiest to install. Its beginning is put on the flue pipe of the column and is fixed with a clamp.The free end is connected to the decorative ring of the chimney duct or the beginning of the chimney pipe. The most important thing is the correspondence of the corrugation diameters to the gas outlet and the flue duct.

Chimneys made of other materials are composed of straight and corner elements. They are standard and specially adapted or made to specifications.

The assembly of elements should be as tight as possible. If necessary, the nodes are sealed with a heat-resistant composition that is not afraid of acid. The entry of one pipe into another should be at least one radius. Joints are strengthened by clamps in free access areas.

The exhaust pipe should not have a deflection, contact with the structures of the house, wiring, other communications. When the product passes through the roof and wall, cutting and heat-resistant insulation are necessary.

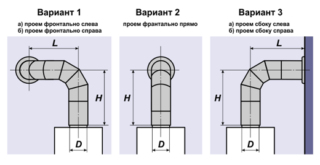

It is permissible to place no more than 3 bends, so there are few types of installation. These requirements apply to columns with an open combustion chamber. The absence of a vertical smoke exhaust channel and the use of a hole in the wall are allowed. In this case, the gas is emitted by a forced exhaust fan. Closed-chamber gas heaters have manufacturer's recommendations.

Unauthorized installation of the speaker in the apartment is not recommended. Commissioning with gas supply is allowed only in the presence of a resource supplying organization. Workers check the system before launch, document the launch conditions and its results.

Connection restrictions

Strict compliance with the rules is important when connecting the chimney yourself. If the installation of equipment is carried out in an individual home, preparatory work should be carried out at the construction stage.

- Each device must have an individual exhaust gas outlet channel. As an exception, it is allowed to combine two devices at a distance of 75 cm.

- The design of the chimney channels must comply with the requirements of building codes.

- Sealing the channels should be complete. Masonry does not give a 100% guarantee.

- The thrust inside the channel should be even. This is achieved by a round cross section and the absence of roughness inside.

- The material of the chimney is made of materials resistant to condensate and acids. In this case, uninterrupted operation and the absence of leakage of combustion products are guaranteed.

- The diameters of the inlet and outlet must match.

- At the bottom of the chimney, a place is provided for cleaning, inspecting and collecting condensate.

- According to SNIPs, gas vents are located near fireproof partitions.

- During the installation of steel ducts, it is assumed that adapters are used to draw the duct.

- The verticality of the pipe outside the room is allowed with a deviation of not more than 30 degrees or 1 m.

It is necessary to place the chimney on a flat roof with a height of at least 2 m. When withdrawing to a gable roof - at least 0.5 m above the ridge.