The air duct is part of the ventilation system of the house and each apartment in particular. Its main function is the inflow or outflow of air masses. There is a large selection of air ducts of various types, which have their own characteristics. The classification is carried out according to various criteria, including the cross-sectional shape, material, method of connection and other parameters. To choose the right system for the home, you should familiarize yourself with the characteristics of each.

Duct classification

Air ducts mean special ventilation ducts that direct air flows in a given direction. They have the ability to adjust the pressure and intensity of the air flow. The channels themselves are a complex system with a large number of branches and elements: hoods, fans, filters, air conditioning.

The criteria by which air ducts can be divided are related to their design, purpose and features of the work.

Sectional shape

According to the cross-sectional shape, the following types of ducts can be distinguished:

- Rectangular and square. This is a traditional view that is most often used in apartment buildings. They are more practical, but at the corners twists can be created. Rectangular systems also include flat ducts. They are almost invisible to the eye, but are able to pass a small amount of air mass.

- Round. They have a smooth profile, so no turbulence is formed. Lungs. The work is silent. Used mainly in large industrial buildings. The diameter depends on the volume of air passing. They are characterized by low weight and reduced material costs.

The cross-sectional area is also different for each ventilation. The dimensions of the ducts are selected individually for various rooms.

The method of connecting parts to each other

Pipes require connection to each other. On this basis distinguish:

- Welded. Contact is made by welding. This is the most reliable and sealed, but the most time-consuming way to connect parts due to the complexity of the process and the need to use a welding machine.

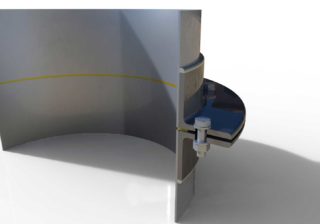

- Flanged. Parts are connected using flanges. This is a method with good tightness and reliability. Requires a wizard for special skills when connecting. The most common contact method.

- Coupling. Connection is made using special pipes.

- Bell-shaped. They differ in assembly speed and ease of installation. The tightness is low.

- Bandage. Used to connect round ducts.

Also, the types of connection include diffusers (expand the air flow) and confusers (narrow the flow), tees, adapters, elbows and duct bends.

The connection result is monitored by commissioning. The system is checked for leaks and lack of purging.

Pipe material

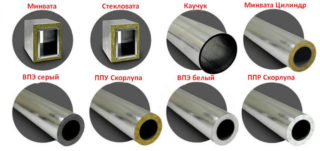

According to the material, air ducts are made of stainless steel, galvanized steel, aluminum, PVC, metal plastic, vinyl plastic, fiberglass.

Steel models are durable, durable and corrosion resistant. They do not require additional maintenance, reduce noise and pressure loss. The use of stainless steel allows you to increase the operating temperature to 500 ° C. Sheet thickness is usually up to 1.2 mm. The main field of application is factories with heavy industry and with increased radiation background.

Galvanized models are suitable for use in temperate climates without aggressive environments.The maximum temperature is limited to 80 ° C. Thanks to the zinc coating, the pipes are protected against corrosion, which extends their service life. Mold and mildew do not form on the walls. They are used in rooms with high humidity (basements, attics, baths, bathrooms, kitchens).

Plastic ducts are also popular due to their low cost, lightness, strength, ease of transportation and lack of rust. Resistant to various chemical compositions and compounds. The main scope is chemical production, pharmaceutical and food enterprises.

Aluminum pipes are flexible and high strength. They hold low and medium pressure in any systems and chimneys. They have good temperature resistance.

Metal-plastic pipes are made of two layers of metals, between which foamed plastic is laid. This is a design with improved strength characteristics with a low weight and aesthetic appearance. No additional thermal insulation is required. The disadvantages include high cost.

Polyethylene is used in ventilation systems. Fiberglass has found its application for the joint of fans and air diffusers. In aggressive environments, vinyl plastic is used, which has the highest corrosion resistance, low weight and the ability to bend to any angle.

Appointment and design features

By purpose, the pipelines are distinguished:

- flexible corrugated;

- semi-rigid;

- thermally insulated;

- fire retardant.

This classification is also related to the scope of the pipe. Fireproof duct system is used only in explosive enterprises. Rigid and flexible ducts are used in homes. At the same time, the main part of the system is made rigid, and a corrugated pipe can be output to connect different devices.

By design, the ducts are straight-seam, spiral-wound, spiral-welded. Straight-seam is also called industrial. They are made of steel sheet with a thickness of 0.55-1.2 mm. There is a seam on the rectangular ducts at the bend, which gives additional strength and rigidity. Spiral-welded models are made from special steel tapes that have a corrosion-resistant coating. Thickness 0.8-2 mm. There are no length restrictions. Joints are overlapped, so the seam is durable and reliable. For spiral-locking systems, steel tapes with an anti-corrosion coating of 0.5-1 mm thickness are selected. The length of the tape can be any. The average width is 130 mm.

Other parameters

Pressure and air velocity criteria are also important when choosing a system. Devices below 900 Pa relate to low pressure installations, from 900 to 2000 Pa - medium, and over 2000 Pa - high. Low-speed ducts have air speeds of up to 15 m / s, and high-speed ones from 15 m / s. In small rooms low-speed systems with low pressure are installed. The remaining types of ventilation ducts are used in high-rise buildings and industrial premises.

Scope of application

The main component of any ventilation system is the duct. Round and rectangular channels are used for transporting air and gas mixtures. Devices have found their application in the following areas:

- industrial enterprises;

- food and pharmaceutical industry;

- medicine;

- catering establishments;

- household purpose;

- laundries, boiler rooms;

- administrative and office premises.

Air ducts are selected for each type of room depending on conditions: temperature, humidity, the presence of chemicals, fire hazard, explosive hazard.

Installation Features

According to the joint venture, the installation of air ducts should be carried out taking into account the following features:

- Flexible products fit only after they are fully stretched.

- Sleeves need to be fixed so that they do not sag. Otherwise, turbulence and stagnation of the air masses will be created.

- It is forbidden to mount flexible and semi-flexible products if the vertical section covers more than two floors.

- In places of contact with soil, in concrete structures, on basement floors, only rigid pipes can be installed.

- Through the walls of the pipe are laid only with the use of special metal sleeves and adapters.

If there are no skills and tools, the installation of the ventilation system must be entrusted to specialists.