With insufficient natural air circulation in the premises - residential, technical, household - install fans. Devices provide air exchange at the level necessary for the operation of the equipment or the creation of comfortable living conditions. The devices operate in a different mode, since during the day the requirements for air exchange change. You can increase or decrease the fan speed using the speed controller.

Rotation speed

A fan in general is a rotor with blades fixed in a certain way. During rotation, the blades collide with the air and discard it in some direction. By design, they distinguish:

- Axial - the direction of the pumped and sucked in breath coincide. The fan is designed to cool anything: coolers in computers, household appliances, mine fans, smoke exhaust devices.

- Radial - centrifugal. Air is sucked in from one side of the fan, is blown out on the other side - at right angles. Radial fans are used in industry.

- Tangential - has a complex structure of the "squirrel wheel" type. Air is sucked along the periphery and is pumped at right angles. This design is in air conditioners, air curtains, refrigerators.

- Flapless - in fact, an air blower. Almost never occurs in everyday life.

Any fan, due to the specifics of the design, operates at full power. This leads to quick wear of the device and breakdowns. The most powerful air flow is not required all the time. To reduce the fan speed, you need to connect a special device.

Element to reduce fan speed

The speed controller adjusts the rotation speed. It can decrease by 2 mechanisms:

- change in current frequency - the lower it is, the smaller the number of revolutions the cooler makes;

- change in voltage supplied to the winding.

In the vast majority of cases, type 2 devices are used. Frequency-changing devices usually cost much more than a fan.

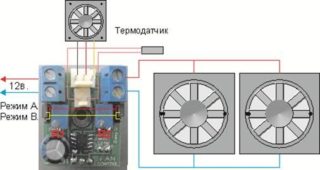

Controllers can be mechanical and automatic. The first are manually adjusted with the wheel. You can reduce it both smoothly and stepwise - it depends on the type of device, most often it is triac models. In complex systems, automatic controllers are installed. Here, a signal to reduce the speed is the indicators of sensors: temperature, humidity, gas, photosensors. Their main task is to reduce energy consumption when the system operates in optimal mode and does not need enhanced cooling.

Extraction fan speed reduction

In forced air conditioning systems usually put duct fans. At maximum power, the devices work only in harsh conditions - an industrial workshop. In company offices, commercial premises, and even in laboratories, the extraction power varies depending on the time of day and the nature of the activity.

To reduce the speed of the channel fan, you need to install a step controller. The regulator reduces the voltage supplied to the winding. In this case, the rotational speed of the blades decreases.The transformer step controller is optimal when the cooler rotation speed is more convenient to manually adjust, for example, to reduce noise at some time.

If the cooler speed is dependent on temperature or humidity level, an electronic module with automatic control is installed.

Automatic controllers are often equipped with alarm indicators, alarm lamps and even the possibility of galvanic isolation from the network.

Controller Purpose

Cooler rotation regulators perform several tasks:

- Energy saving - at maximum power the fan consumes the maximum amount of electricity. It is not profitable. The ability to reduce the number of revolutions when there is no need for this allows you to reduce electricity bills.

- Increased equipment life - the fan includes moving parts. With intensive work, they quickly wear out and fail. By reducing the speed, you can increase the life of the hood, air conditioner, refrigerator.

- Noise reduction - a fan at maximum power produces relatively little noise. But if there are several devices, the noise level exceeds tolerable 50 dB. If you lower the speed, the noise is also reduced.

- Support for continuous mode - without a controller, the fan can only be in 2 states: full power operation and shutdown. When working in a ventilation system, the device periodically turns on and off. This mode leads to overheating of the device and excessive consumption of electricity. The controller provides an inverse principle of operation: reducing and increasing the number of revolutions without power surges.

The controller can be installed on exhaust systems in the kitchen or office ventilation, as well as on household appliances and equipment: refrigerators, computers.

Main varieties

To reduce or increase the fan speed, you need to choose a device of the necessary design. There are several types of controllers. The most famous classification is based on the principle of management. However, they all relate to devices that change the magnitude of the voltage across the winding.

Thyristor or Triac

Designed to work with single-phase devices that have protection against overheating. The principle of phase control is realized here. 2 thyristors connected in counter-parallel form a triac. When the voltage passes through zero, the thyristor “cuts off” the part at the beginning or at the end of the voltage wave, depending on the control circuit. As a result, the rms voltage changes.

Thyristor controllers are efficient, compact, and generate little noise. However, they can only be connected to electric motors designed with this in mind.

With a network frequency of 50 Hz, triac controllers act worse: jerks and noise are heard during operation.

Frequency

Change the frequency of the voltage supplied to the fan. With their help, voltage is obtained from 0 to 480 V. Frequency controllers are the main way of adjustment in inverter devices: air conditioners, converters. However, the regulator can only work with three-phase electric motors, which limits its use.

Transformer

Models are designed to provide the most powerful fans. Single and three-phase devices are produced. Most often these are step regulators. They increase and decrease the voltage at a certain interval, which is indicated in the marking. However, there are options that provide smooth adjustment.

Transformer regulators are bulky, inexpensive. The device can be mounted on walls, inside walls, directly inside the unit. The controller can serve several fans and is highly reliable.

Device Connection Rules

A controller can be mounted and adjusted by a specialist to reduce fan speed. In simple cases, they cope with this task on their own.

The installation methods of the controllers depend on the type of device: wall-mounted, wall-mounted version, model for installation inside the case, reobas for adjusting the rotation of coolers in the system unit, etc. The controller connection diagram is available in the instrument manual. After studying the manual, you can figure out how to connect the device and maintain it.

- Wall and wall options are fixed to the wall with screws or dowels. Fasteners are usually included.

- The regulator is connected to the power cable according to the scheme given by the manufacturer. The task boils down to trimming the wires of zero, phase and earth and the serial connection of the wires to the input and output terminals.

- Before starting the installation, you need to make sure that the cross section of the connecting supply cable corresponds to the maximum current of the connected controller.

- If the fan is equipped with its own switch. The latter must be dismantled and replaced with a controller.

To reduce the speed of the computer cooler, use an additional resistance device or its improved version - reobas. Preliminary work here is more complicated. It is necessary to correctly assess what is the permissible temperature for each item of equipment: the motherboard, the processor of the graphics card. Otherwise, a decrease in the cooler speed leads to overheating and breakdown of the processor or board.

The principle of connecting the reobas: the wires from the fan are cut off and connected to the controller according to the scheme specified by the manufacturer. Reobas is more convenient because it controls several fans at once, while additional resistance reduces the speed of only 1 device.

DIY assembly

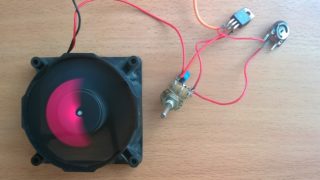

The controller is a resistance connected in a specific circuit. You can do it yourself with the simplest option to control a household fan. It will take 3 parts for this: variable and constant resistors and a transistor.

- The base of the variable resistor is soldered to the base of the transistor. A collector is connected to the extreme terminal of the resistor.

- A solder of 1 kOhm resistance is attached to the other edge of the resistor by soldering. The second terminal of the constant resistor is soldered to the emitter of the transistor.

- An input voltage cable is attached to the transistor's collector, and the “positive” output is fixed to the emitter of the transistor.

- To check the operation of the element, the wire from the emitter is connected to the "plus" wire of the fan. A wire of output voltage from a home-made reboas is connected to a power supply. The "negative" fan wire is attached directly, not including the regulator in the circuit.

- Turn on the power supply. Reduce and increase the speed of rotation of the cooler by turning the wheel of a variable resistor.

Homemade is completely safe for the fan, since the "negative" wire is connected directly. Even if the controller closes, the cooler will not suffer.