The formation of condensate in ventilation, on building structures, in any other place is accompanied by a complex of problems, ranging from high humidity and ending with the development of pathogenic flora. In addition, the chemical composition of the water itself is quite aggressive and capable of exerting a destructive effect on concrete and metal elements, so it is necessary to find a way to eliminate condensation in the ventilation in a private house. For this, first of all, it is necessary to understand the reasons for its occurrence.

Why moisture appears in a private house in ventilation

If condensation drips from the chimney, there can be many reasons. It is rare that he is completely absent. Given this, moisture removal devices have been developed for filter ventilation systems and chimneys. If the water drains from the canals in streams, it makes sense to think about the serviceability of the hood. The most common reason is a non-insulated mine, but this is the only factor.

Temperature differences

The problem arises when the outside temperature is kept at a negative temperature for a long time. In this case, in the upper part, icicles accumulate at the ventilation outlet due to the freezing of water vapor, which is present in the air leaving the room. The situation is aggravated with the duration of this temperature regime, since the heated air from the building partially melts the ice and drops flow down the walls of the mine.

This situation is usually not a consequence of improper organization of the hood and may occur from time to time.

Installation with errors

Condensation on the hood in a private house may appear due to errors in the arrangement of the system. Properly stacked shafts should be located strictly rectilinearly, with minimal bends and transitions. The presence of turns slows down the air flow, gives time to cool the steam on the walls.

The second important point concerns the strict observance of the internal diameter of the duct. Inconsistency with its developed project or the presence of narrowing sites also contributes to a decrease in the speed of movement of air masses and the release of drops on the walls.

Insufficient air exchange

Most often, the reason arises in multi-apartment apartment buildings with a common filter ventilation system. The essence of the problem lies in the fact that during operation in the internal passage of the hood a spider web appears, fat deposits form, garbage accumulates, for example, in the form of particles of fallen leaves. All this leads to a decrease in the cross section of the passage and prevents the flow of air.

It will not be possible to solve the problem on their own in case of pollution of the public hood. It is necessary to call the service team to carry out cleaning measures along the entire length of the duct.

The presence of water in the basement

The basement has one feature - it always has a positive temperature, even in winter. If for some reason there is water here, it will evaporate in any case. Properly organized filtration ventilation first of all has access to the basement. Together with air, steam will rise up the shaft. Having reached the point of low temperature, moisture creates condensation in the ventilation.

Basements in the zone of high groundwater should be waterproofed, water communications in such places should be operational and not leak.

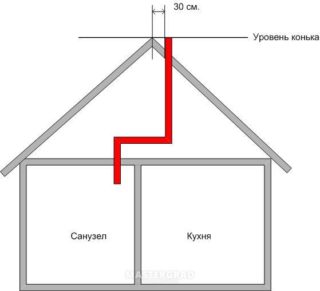

The pipe is not insulated

If the duct is designed in such a way that part of its structure passes through a section of the room where there is no heating, moisture can form in this period during the cold period when a certain volume of steam is cooled. Therefore, air ducts in areas of cold and negative temperatures are insulated. The efficiency of insulation must be sufficient, which depends primarily on the difference in temperature difference and the duct material itself. The metal structure should be warmed more thoroughly than the plastic one.

Defective building material

If there are some irregularities on the inner walls of the pipes, this does not greatly affect the formation of water droplets. Attention should be paid to the quality of the material used to warm the entire system. Non-compliance of the latter with the operating conditions can lead to a loss of thermal insulation properties, and then the walls will cool, condensation will begin to form on the exhaust pipe.

Attention should be paid to the good sealing of the joints of the structure itself. Steam or moisture seeping through leaks can enter mineral wool and reduce its performance.

Design miscalculations

Before laying the filter ventilation system in the house, it is necessary to calculate the performance of the system as a whole and its individual elements. This means primarily the bandwidth of the channels and the power of the electric hood itself. According to building codes and rules for each room of a dwelling there are requirements for air exchange:

- in living rooms, bedrooms and hallways, 3 cubic meters of air should be changed within one hour in terms of 1 square of the area;

- for the kitchen, the volume increases to 8-6 cubic meters;

- in the toilet, this figure reaches 10-8 units;

- 9–7 cubic meters per square meter are sufficient for showers and bathtubs.

Dry cellars also need to be ventilated, it is enough to provide air exchange within 6-4 cubic meters. These conditions must be observed exactly or a small margin in performance should be made, but in the latter case it is important not to overdo it, otherwise additional heat loss will result.

How to identify a problem

Typically, filter ventilation is a complex technical device with many branches. It is not always possible to disassemble it and see where drops form, for a number of reasons. In this case, it is necessary to approach the solution of the problem by an indirect method - to look for signs of a defect on the outside.

The first sign of water formation on the walls of the metal channel may be rust patches. If the shaft is closed with insulation, wet areas will still appear, making the insulation material itself moist. In this case, the damaged material is removed, a new one is put in its place.

Another potentially problematic place may be a section of the duct that rises above the roofing. In order to save, they do not always organize insulation in this place, which often leads to icing of the material.

Proper organization of insulation

The ins and outs of warming a particular filter ventilation system depend on the material, the cross section of the ventilation hole and the type of insulation. Until recently, the main insulation, which was used universally, was different types of mineral-based watts and glass wool. Today, the choice is much greater. Shell insulators - cylindrical spans of two halves with different inner diameters - are gaining popularity.With these elements, installation is carried out quite easily by putting parts on the duct and fastening together with a wire or with tape. Half-cylinders are made from various foams, as well as mineral-based cotton wool.

Full-fledged warming of supply and exhaust ventilation is reduced to such moments:

- All pipes that are in unheated conditions provide thermal insulation. In private households, such places can be attics, cold basements, garages.

- If the shaft body is adjacent to the ceiling, and the attic floor does not have a heater, the channel is also insulated.

When passing through the thickness of concrete, direct contact with metal structures also forces the air duct to be wrapped.

Work with heaters, especially all types of watts, should be carried out only in dry weather. When wet, this material loses its technical properties.

How to get rid of condensation in the vent pipe

One of the effective methods to get rid of excess moisture is to equip the system with steam traps. The mechanism of these devices is constructed in such a way that allows trapping water that flows down the walls towards the slope.

In fact, the steam trap is a tee with a cone-shaped capacity, cut into the bottom of the line in the horizontal section and at the base of the turn by 90 degrees when moving from the horizontal direction vertically upwards. This method will get rid of moisture and precipitation falling into the canal during rain.

Further, it is simply necessary to pass through the entire site with a given frequency and drain the liquid from the traps. It is possible to automatically drain moisture by equipping each steam trap with an electric valve.

What experts advise

Based on the experience of operating various ventilation systems, experts recommend:

- Insulate duct lines in unheated areas with polyurethane foam heaters. When using mineral watts, waterproof the base before and after laying the heat insulator.

- On long sections of the passage of the duct along the street, equip it with steam traps for ventilation.

- The end of the upper pipe towering above the roof should be equipped with a protective visor.

- Equipment with high humidity should be equipped with a local exhaust fan.

It is necessary to periodically audit the entire line as a whole and problem areas in particular. To do this, it is necessary to organize the channel in such a way that inspection hatches are easily accessible.