The ventilation system is a complex pattern of air movement, including straight pipe sections, branches, technological elements and other functional devices. Installation of air ducts is determined by the material, the shape of the channels and depends on the location in the building. The pipe system provides fresh air and exhaust from the room.

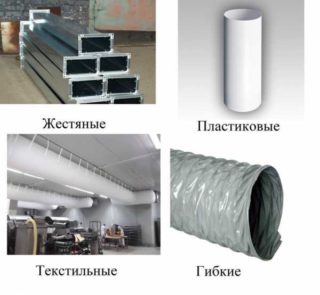

Types and types of ducts

The main network of channels, shafts and hoses cleans the microclimate from gas and other impurities, coordinates the intensity and pressure of flows, for this a natural or forced method is used. Ducts are classified according to purpose and technical parameters.

Classification by characteristics:

- cross-sectional shape: oval, round, square and rectangular;

- wall size, cross-sectional area, diameter;

- constructive model: straight-seam or spiral;

- mechanical rigidity or deformation resistance ability;

- production material: stainless steel, galvanization, plastic, metal-plastic;

- mounting method during installation: without flanges or flanged.

It is important to use diffusers to slow down the flow or confusers to accelerate. In the trunk, bends, tees, straight and transition fittings are used.

Stiffness

The fastening of hard-type ducts is more often done, so a significant part of the equipment focuses on static ducts. The channels are rectangular or round in diameter. The material is hard sheet metal or plastic. Steel channels are made on bending machines, and plastic elements are pressed through the extruders.

Are operated in conditions where durability of channels is required. Rigid lines are easy to maintain and install, they have high aerodynamic characteristics. The disadvantages include an increase in the weight of extended structures due to many turns and adapters, therefore, additional fastening of the branch is required.

Flexible ducts are a corrugated pipe, they are called spiral. Laminated foil walls are made on the basis of steel wire reinforcement. Flexible boxes easily bend in the right direction, do not require connecting elements. An internal corrugated wall reduces air velocity and increases noise levels.

Semi-rigid air ducts are made of steel or aluminum tapes, which are rolled into a pipe. Products have spiral side seams. Boxes are characterized by enhanced strength compared to flexible types and almost do not require connecting and swivel fittings in the duct scheme. The disadvantage is the same as that of flexible channels - a relief surface inside.

In shape

More often round and rectangular boxes are used, in conditions of lack of space they use an oval shape. Such a cross-section of the pipe is obtained from round on technological equipment. Rectangular channels require more labor in manufacturing, they take 20 - 25% more metal than other types.

Round pipes provide high air speed due to the low resistance of the walls, they are leakproof, low noise and less weight. Rectangular and square channels are optimally placed in space and adapt to interior elements.In industrial buildings, round air pipes are arranged, and private buildings make installation of rectangular ventilation ducts.

By material

Boxes with galvanized walls are installed in a temperate climate with low aggressiveness of the ambient air, the temperature of which cannot be higher than + 80 ° С. The zinc layer on the surface protects against corrosion, extends the service life of the main, but adds the cost of the ventilation system. Galvanization is recommended for high humidity, as fungus and mold does not develop on the material.

The stainless steel withstands the temperature of the surrounding space up to + 500 ° C, because it is characterized by heat resistance. Laying ducts is done in industrial workshops with hot production. Thin sheet stainless steel is used without a decorative coating or a polymer layer is sprayed in different colors. The anticorrosive properties of the metal are manifested due to the inclusion of phosphorus, chromium, copper and nickel in the chemical composition.

The walls of the metal-plastic duct have 3 layers:

- two outer layers of metal;

- foam plastic interlayer.

Designs are characterized by durability, does not require additional thermal insulation, but are of high cost.

Plastic boxes made of modified polyvinyl chloride do not respond to moisture, acid and alkaline fumes. They are used for ventilation in the pharmaceutical, chemical and food industries. Smooth inner walls do not inhibit flow and minimize pressure loss. Sometimes metal collectors are connected and turned with knees, elbows and PVC tees.

Ducts made of polyethylene and fiberglass are used in the intake sections of the system for connecting the air distribution branch to the fan. Viniplast types of boxes resist acid fumes, easily bend.

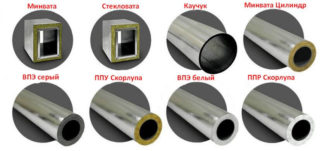

Insulation

Installation of ventilation ducts is carried out inside the building and outside. Street sections are isolated from the cold, because the temperature difference causes condensation to drop out. Moisture contains acids and alkalis, which destroy the walls of the ventilation shaft and shorten the life of the line.

Used stone wool, fiberglass loose heaters. For rectangular ducts, sheet insulation is used in the form of foam, polyurethane foam, foamed polystyrene foam. Indoors, such insulation can be neglected.

Insulation is done from the cold and from noise. In the bedroom, children's room, study, living room, the walls of the duct are duplicated by sound-absorbing layers. The problem is solved by the use of three-layer pipes, for example, metal-plastic pipes or by installing vibration-damping devices in the system.

General installation rules

The scheme is made so that the highway has a minimum number of turns and connecting sections. At the stage of technical design, the requirements for indoor air exchange are taken into account, the number of people and the volume of the room are taken into account.

Mounting ventilation is carried out in the sequence:

- Before installation, the system is divided into separate branches, the length of which does not exceed 12 - 15 meters;

- connection points are put on the parts and holes are drilled;

- line elements of a separate section must be secured with bolts, clamps, the connections are fixed with tape or insulating sealant.

The assembled blocks and units are combined into a single chain, the pipeline is fastened to a partition, wall, ceiling or is removed through the roof.

Wall mount

Clamps, supports, pendants are mounted in increments of not more than 4 meters for the installation of horizontal ducts. Such a step is relevant if the diameter of the round pipe or the largest side of the rectangular section does not exceed 40 cm. The step distance is reduced to 3 meters if the indicated channel dimensions exceed 40 cm.

A step of 6 meters is envisaged for air ducts on the flanges of round or rectangular channels with the largest side of the cross section up to 20 cm or insulated pipes of different sections. If the dimensions exceed the specified value, the step is calculated in the project. Vertical fastening of ventilation pipes to the wall is carried out through a gap of not more than 4 meters. Mounting on the roof and outside of the building is indicated in the design and is taken as calculated.

Ceiling mount

The duct is fixed to the ceiling in 50% of cases if it is not possible to mount the ventilation to the wall. For suspension, pendants, studs and brackets are used.

Mounting Options:

- Small pipes are hung with an L-shaped bracket, self-tapping screws are used. Suspensions are fixed to the ceiling or beam by dowels (in concrete), by self-tapping screws (into wood).

- Z-shaped studs are used to install rectangular channels, and the fastening of the ducts to the ceiling is carried out similarly to the previous case. Due to the extra angle on the bracket, the load on the supporting hardware is reduced, and the strength is increased.

- V - shaped pendants are fixed to the upper ceiling with anchors. This type of suspension can withstand significant loads.

If the ceiling material is not suitable for fixing the elements of the duct, make vertical supports for the highway. Normally, stretch marks cannot be attached to the flanges; all suspensions must have the same tension. Hanging air ducts are fastened with double suspensions, if the size of the supporting elements is 0.5 - 1.5 m. The brackets are shot with dowels using a construction gun.

Standard distances according to GOST

The installation standards are prescribed in the SNiP document 3.05.01 - 1985, and the design takes into account the norms for the location of air ducts from SNiP 2.04.05.1991. The central axis of the highway should run parallel to the plane of the building envelope.

Standard distances are maintained:

- from the top of the round pipe to the ceiling should be at least 10 cm, and to nearby walls - 5 cm;

- from a round channel to a hot and cold water supply system, gas pipeline, sewage system must be at least 25 cm;

- from the outer wall of the square and round pipes to the electrical wiring - at least 30 cm.

- when attaching rectangular ducts, the distance to the walls, ceiling, and other pipelines is not less than 10 cm (section width 10 - 40 cm), not less than 20 cm (width 40 - 80 cm), more than 40 cm (size 80 - 150 cm).

Compounds of various types are placed at a distance of not less than 1 meter from the place of passage through the walls, ceiling.

Features of duct installation

A well-designed ventilation line will not work effectively if you violate the technology of installing elements in a common system. The supply system includes one pipeline, and the supply and exhaust system provides two independent channels for supplying a clean flow and exhaust air.

Outdoors, the areas are protected from the action of aggressive factors, for example, sunlight, frost, rain, icing. A flexible polyester duct loses shape when installed close to a heating main.

Channels, the walls of which are made of various materials, should also not be contacted to extend the service life. The negative effect on the walls of PVC pipes is exerted by static electricity. Accumulation of discharge in combination with explosive vapors can lead to an accident.

Mounting Methods

The stud and traverse method is used for hanging rectangular channels whose width exceeds 60 cm. The traverse supports from the bottom, and the side studs are fixed from shifting to the side. This mount is suitable for insulated walkways, assurface integrity is not damaged by screws.

The method of studs and clamps is used to fix the round pipe. Fasteners are available in different sizes and have rubber seals inside to reduce vibration. A stud with a clamp is fixed to the ceiling with a metal anchor or plastic dowel (small channels). The bottom of the mount is removed, the ventilation pipe is placed, then the clamp is tightened back.

The budget method using punched tape is used for channels of different sections of light weight. Pieces of tape encircle the pipeline and are fixed to the ceiling or beam with the ends. This method does not provide a rigid fixation, and the line can be depressurized under vibration.

The stud and profile method is used for different sections. Two curly parts are placed on the sides of the ventilation duct and screwed with screws. On one side there is a hole for connecting to the stud, which is laid with a rubber seal to reduce noise and vibration.

Types of connections

It is recommended to reduce the number of interfaces, but it is difficult to completely avoid such sites. Assembly is carried out by a flange or bandage method.

In the first case, flanges with holes are provided on the connecting surfaces of the shaped elements and the ends of the channels. The connection is made with screws, bolts and nuts, rivets with a pitch of 20 cm. Some types of ventilation ducts are connected by welding. When assembling, rubber gaskets are used for sealing. Flange manufacturing is an expensive process and has been rarely used in recent years.

Flangeless or bandage coupling costs less and less labor is required to complete it. A belt is used that overlays the joint and is a strip of metal or plastic. The connection is characterized by low tightness, and with a difference in temperature, condensation appears here.

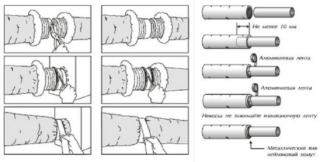

Flexible duct

Corrugated sleeves without insulation have a length of 10 m, and with a heater are available in size of 7, 6 meters. The diameter of such products ranges from 7 to 20 centimeters.

Installation Features:

- before installation, flexible hoses stretch to the full length;

- on the packaging of the element there is an indication of the direction of air, this designation must be taken into account during installation;

- the normative distance to adjacent pipelines and elements is maintained;

- bending radius should not exceed the size of the double diameter of the pipe;

- clamps made of plastic, adhesive tape with foil, clips and pendants are used for fastening;

- special sleeves are used to pass through a wall or ceiling.

When connecting two sections, the pipe is put on to a depth of not less than 5 cm. The joints are treated with sealing compounds. In insulated channels, the insulation edge is turned off before the connection, and after the procedure, it is put in place and fixed.

Hard duct

The metal sections of the channels are connected on the floor, and in the installation position are installed in the complex using lifting equipment.

Rules for installing hard lines:

- air ducts are fixed to the ceiling at design elevations or a beam system of vertical elements is placed to support it;

- it is taken into account that space is required for the installation of scaffolding, scaffolding and lifting devices;

- all connections are made using gaskets, tightening and supporting clamps and sealing compounds are used;

- fasteners are mounted on a previously applied marking line.

Attention is paid to the articulation of the last section of the duct with the outlet pipe to the outside of the building. Steel pipelines in industrial halls are laid between supporting ceiling trusses.This method is more time-consuming, but allows you to save the working height of the room.

Insulated duct

Difficulty arises when connecting sections, tees and bends. Shaped elements do not always have an insulation layer, therefore, after the procedure is completed, additional materials are placed on the surface of the flanges or fittings.

During connection and installation, it is necessary to try to damage the layer as little as possible, use lateral clamping strips to avoid the use of self-tapping screws. Thermal insulation is fastened with adhesive tape, clamps and aluminum tape.

Duct Installation Safety

Reliable scaffolds (at home), certified forests (on an industrial scale) are used to work at height. Safety belts must be used. Safety glasses and gloves are worn when working with cotton insulation that releases fibrous impurities into the atmosphere.

Insulation cutting is carried out with a well-sharpened tool, preferably at a time, so that the material does not become soaked. If harmful substances get into the eyes, they are washed with a large volume of water and immediately consult a doctor. Specialists wear non-slip shoes for work on the scaffolds and protective helmets on their heads.

Selection and calculation of ducts

The calculation of the cross-section and pressure in the duct is carried out by technical experts, it is difficult to do it yourself. The line is selected taking into account the required rate of air exchange per hour. The project takes into account the harmfulness of production, the number of people in the house or office. There are rooms from which air is removed in isolation and does not mix with flows from other rooms. These are chemical laboratories, hospitals, harmful production facilities.

Small-sized pipelines are taken for private buildings, attention is paid to high-quality cleaning of streams, moistening. The method of air movement is chosen - natural or forced. The material of the boxes and the shape is determined by the technical characteristics, customer preferences and the interior of the room.