Automation of ventilation systems is used to optimize the operation of this type of equipment in a house or industrial premises, to provide smoke protection, and to prevent fires. To improve your goals, you need to choose the right installation.

Determination of functional indicators of ventilation systems

If automation of ventilation systems is planned in the room, when choosing a installation, you need to focus on achieving values that are appropriate for this type of room. The regulations provide for periodic checks of the quality of ventilation. If it was found that the values of the indicators are less than they should be in theory, the installation is supposed to be improved (for example, to automate) or to be repaired.

Traditionally, parameters characterizing the quality of ventilation include:

- the amount of inflow or outflow of air mass per hour;

- the ratio of the area of the sash through which ventilation is carried out and the floor of the room;

- air change rate per hour.

These criteria are used in hospital and other medical facilities, laboratories, catering establishments and other places where it is important to take special care of sanitation.

In industrial buildings, measurements of the content of carbon dioxide in the air and the study of its composition through gas and aerosol analysis are more often used.

Technical means

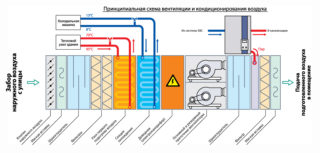

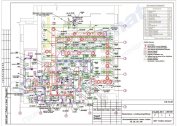

Devices through which automation of ventilation of general exchange and other types is implemented, as well as air conditioning, are very diverse. The scheme may include different types of sensors (temperature of incoming and outgoing flows, pressure, humidity, carbon dioxide content), control units, actuators, devices that control electric drives. The performance indicators of these devices, the monitoring of which is important for the effective functioning of the installation, are displayed on the control panels and control panels.

It is possible to automatically control data when moving away from the specified frames or manage them in the submenus. From the sensors, the signals are sent to the control cabinet, where they are subjected to analytical processing with the selection of a suitable algorithm for the air conditioning system.

Advantages and disadvantages

Automation of supply and exhaust ventilation allows you to optimize the operation of the installation, monitor compliance with the target indicators. At the same time, the participation of a person in process control is minimized, which allows production workers or institutions to devote more time to other tasks. At the same time, when planning the connection of ventilation automation, it is important to correctly calculate, estimate and select devices compatible with each other that will ensure the proper level of air supply with a minimum of wasteful costs. The disadvantages include the possibility of breaking complex electronics.

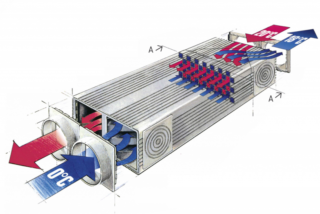

Automated operation of the ventilation system allows you to save resources due to several factors. This includes precise adjustment of the modes of technology, the subordination of the work schedule. In addition, in the winter, the functioning of the heat exchanger is maintained (which prevents its freezing) in parallel with minimizing heat consumption.This allows you to optimize the work in the cold season.

The main sections of the automation of ventilation systems

In the operation and automation of ventilation systems, proper selection of installation components is of great importance. It is determined by the purpose of the design configuration.

Automation system for modular ventilation systems

Modular units are assembled from separate components: noise mufflers, air ducts, air heaters, etc. They are simple and reliable. The ventilation control unit must maintain a predetermined indoor temperature, protect the air heater from freezing, control the fan torsion speed. It consists of the following components:

- Sensors measuring various indicators: temperature, humidity, etc. They are selected depending on the conditions of use of the installation and how accurate the measurements should be.

- Regulating devices that control actuators based on sensor data.

- Control devices.

- Equipment for data entry.

- Executive mechanisms.

The electronic control unit and part of the executive components are often combined inside the automation panel.

Automation system for fire ventilation systems

This includes various fire protection installations that equip rooms and buildings with a high risk of fire. They include signaling devices, equipment for automatic fire extinguishing, smoke protection, and assistance in evacuation. Firefighting equipment of buildings also includes special internal water supply and elevator compartments for relevant specialists. Equipment of this kind should inform people inside the building about a fire, limit the spread of burning, help in the implementation of evacuation measures. The installation can be blocked for the receipt of additional doses of a fire extinguisher, creating obstacles to the fire.

Automation system for central air conditioning

Equipment controlled by such systems is intended for climate control in various rooms of industrial or commercial use. This includes various types of refrigeration and air conditioning equipment. Automatic control units are usually built into the equipment itself or supplied by the manufacturer together with it. Design and manufacture of automation for a specific installation according to the technical requirements prepared by the customer are widespread.

Automatic ventilation control helps maintain target parameters within specified limits, minimizing staff intervention. The main components of the systems are different types of sensors and electronic control units located in the automation panels.