Industrial ventilation is a complex of climatic devices and technological devices that guarantee high-quality air exchange in large spaces. The effectiveness of such systems is assessed by their ability to quickly and efficiently replace exhaust air with clean masses. In addition, their functions include maintaining a microclimate in the premises at a comfortable level, taking into account compliance with the requirements of ecology and sanitation.

Industrial ventilation requirements

The general purpose of industrial ventilation systems (SV) is the forced pumping of significant volumes of air. Therefore, it is important that they have appropriate indicators for the developed pressure and air flow rate. When designing such complexes, their compliance is also taken into account:

- the requirements of sanitation and hygienic control, determining the speed of localization and removal of harmful secretions and creating a comfortable environment;

- noise standards of operating equipment;

- fire safety requirements;

- the provisions of current standards, specifying installation methods and ease of maintenance of systems;

- energy saving requirements and environmental standards.

The characteristics of ventilation, equipped at industrial enterprises, are negotiated at the design stage of the facility. The main guidance document is SNiP 2.04.05-91 “Heating, ventilation and air conditioning”.

Types of industrial systems

According to the existing classification, the following types of ventilation of industrial premises are distinguished:

- general exchange, including natural and mechanical varieties;

- local ventilation equipment;

- local systems.

The first in the list of equipment for ventilation of industrial premises in the presence of two varieties performs one function - it makes the air in the rooms cleaner. The main task of local ventilation is the removal of contaminated air directly from the site of its formation, which reduces the power of communal buildings. It includes:

- air curtains and jets;

- exhaust umbrellas;

- suction panels.

Air curtains are special devices that drive air with high speed around the perimeter of the entrance structures of industrial buildings (doors or gates). They are used if there are technological openings at the facility that remain open for a long time. Curtains and jets are made with heating or dispense with it. For their installation, convenient zones are selected above the aisles and above the entrance doors that do not have vestibules (at air temperatures below 15 ° C).

Exhaust hoods are designed for suction of secretions with a density not exceeding the same indicator for ambient air. This cleaning method is effective only with a certain ratio of contaminated and clean air masses. Suction panels are used to localize harmful fumes in convective jets, if you can not do this in other ways. They are mounted on the sides of the source of pollution in a vertical or inclined form. The distance between them does not exceed the width of the evaporator, and the length of the panel is made equal to its double value.

Technological parts of industrial ventilation

The choice of type of ventilation units for industrial premises depends on the category of the serviced object. In most cases, supply and exhaust circulation systems are installed at enterprises, the only drawback of which is the need to connect to the mains. Even with not very powerful fans when servicing large spaces, the cost of electricity will be significant.

On the other hand, systems of industrial supply and exhaust ventilation are more efficient and allow expanding the functionality of production complexes. If desired, they are combined into different purpose systems or are used in the recovery mode. These devices guarantee economical energy consumption, since the heat exchange in them occurs without direct contact. Thanks to them, the efficiency of the system is increased and the cost of its maintenance is reduced.

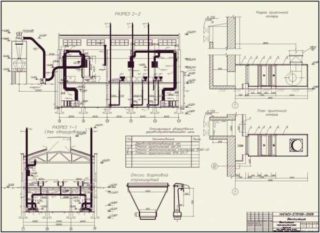

Another common type of ventilation unit is represented by complex systems for which separate rooms are allocated. The latter is explained by the significant dimensions of compatible devices (a filtration system is often included in their composition).

The largest and most expensive solution is the combination of air heating and air conditioning. The built-in air heater is responsible for heating the air in them, and the air conditioning system performs the cooling function. Special technological equipment is used to clean air from fine dry particles.

Tasks and features of an industrial ventilation system

Industrial ventilation equipment is designed to solve the following problems:

- creating a comfortable environment suitable for a long stay of a person in the room, as well as to maintain a continuous production process;

- maintaining air temperature and humidity within the limits regulated by current regulatory documents;

- creating optimal conditions for updating air and removing toxic substances outside the premises;

- targeted provision of jobs with fresh supply air.

The above tasks are fully solved, since not only the well-being and health of industrial workers, but also the effectiveness of the entire technological process depends on them.

Ventilation systems of production areas that do not meet the specified requirements will not be accepted by the commission when they are put into operation. Their features include the presence of three stages of purification of air masses. For collecting dust particles up to 10 microns in size, filtering equipment for fine air purification is installed in the supply air channels. Medium purification filters are used in the exhaust ducts to precipitate larger formations of 10-100 microns, and coarse filtration is used for contaminants with a particle size of more than 100 microns.

Project preparation steps

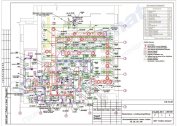

Design of industrial hood plants begins with the preparatory phase - the collection of all necessary documentation, including diagrams and sketches of the complex being developed. The success of creating a reliable and efficient ventilation system for industrial premises largely depends on the correct organization and conduct of this stage of work. The preparatory stage with a competently performed calculation of the system determines its following indicators:

- the cost of the entire installation;

- performance characteristics;

- ease of installation and operation.

The main factor taken into account when collecting information is the reliability of the developed system. Any mistake at this stage leads to the need to re-develop the project and to additional costs.

To proceed to the next stage is allowed only after all the necessary information has been collected, as well as:

- the purpose of the facility (premises) is determined in accordance with the general construction plan;

- All sizes are considered;

- A detailed scheme and a full set of executive drawings are ready.

At this stage, you will also need to take into account all the details and features of the object, the specifics of its design and the validity of the selected technological solutions.

Technical specifications

When preparing a project for industrial ventilation, developers take into account the features of the premises that make up the facility and relating to fire safety standards and requirements. Using special software, designers work on the main points related to the constructive side of the issue. The latter are drawn up in the form of technical specifications (TU), including the following items:

- the composition of the ventilation system indicating the full name of the components and their sizes;

- structural characteristics of the air heater, including duct layouts;

- aerodynamic features of the developed complex;

- acoustic characteristics indicating the need for additional insulation of air channels and other issues.

A ready-made set of documentation, including technical specifications, is used during installation of equipment at a serviced object.