A special corrugation for hoods is used when installing additional equipment for the ventilation system in the kitchen or in the bathroom and is an integral element of the overall design. The corrugated pipe is divided into several varieties depending on the appearance, material and manufacturing method. Before buying such an element, it is worth exploring in detail its scope, pros and cons, the available installation and installation options.

Features of the structure of the corrugation for hoods

The corrugation for ventilation is a corrugated pipe that is mounted between equipment that provides circulation and air exhaust to the ventilation system of the building or to the external environment. It is a flexible element due to the design and production technology. The pipe is often used to install ducts in hard-to-reach places; most of these elements do not need additional decoration and shelter due to the universal design.

The list of basic technical characteristics of the corrugation intended for drawing includes length and diameter. The length of the element is determined by the manufacturer, the pipe can have a standard size and sold in bays. According to the cross-sectional shape, the corrugation is rectangular or round. The diameter of the ducts varies between 10-30 cm; for their manufacture, aluminum, plastic, polyethylene, textile, aluminum or stainless steel are most often used.

Corrugated Tube Classification

The corrugation vent is actively used at the device of communications. The element is popular due to its high strength, a large selection of sizes and materials, as well as a long life. There are various types of pipes on the market, ranging from plastic color models of small diameter to large culvert corrugations made of stainless steel. To choose the right model, you need to understand the types of pipes and know how they differ from each other.

In appearance

In appearance and shape, the pipes can be round or rectangular. Models of the second type are mainly used at production facilities. The round options are designed for home ventilation systems, most often experts install spiral-wound type corrugations in houses made of plastic, aluminum, galvanized or stainless steel.

According to the material of manufacture

Elements made of aluminum are used for indoor and outdoor installation, the list of their main advantages includes light weight and medium frame rigidity. Such corrugations can be used at different temperature conditions for a long period. They also have disadvantages, this is an increased noise level and vibration during operation.

Plastic pipes are popular because of the low cost and ease of installation, they have a minimum level of resistance to air flow and are presented in a large number of options. At the same time they are subject to fire and destruction, and also emit harmful fumes during combustion.

Elements made of stainless and galvanized steel are durable, non-combustible and odorless, but are more expensive.

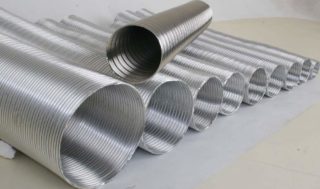

According to the manufacturing method

According to the manufacturing method, the corrugated pipe intended for ventilation can be frame or spiral-wound.The element of the first type is a metal frame covered with a film or foil. Such ducts are quite flexible and able to return to their original shape even after stretching. Corrugations of the second type are made of metal tapes. In finished form, they can stretch two or three times, but they are not able to return to their original state. To give the desired shape, such pipes have to make efforts, while traces of deformation will no longer be eliminated.

Scope of application

Each corrugated pipe for drawing has its own field of application depending on its type. Plastic elements are used for laying electric cables, most often they are corrugations with a diameter of 1.6-4 cm. Steel pipes are ideal for arranging heating systems due to the absence of installation problems. For ventilation systems, corrugated flexible pipes with a diameter of 10-15 cm are used. Textile ducts are more suitable for installation of communications in industrial premises, since they do not interfere with the rapid transfer of air inside the space.

Corrugated pipes made of polyethylene or plastic are best used to connect plumbing or supply water to washing or dishwashers.

Advantages and disadvantages

A corrugated pipe designed for drawing has many advantages that make such an element indispensable in the process of installation. Before the appearance of exhaust corrugations during the installation of rigid structures, it was necessary to order air ducts according to individual designs for specific rooms. The list of the main advantages of corrugated pipes includes:

- long terms of operation;

- reasonable prices and the absence of installation problems;

- large selection of sizes;

- strength and ability to withstand high temperatures;

- optimal aerodynamic performance;

- light weight.

The list of disadvantages is usually made by problems associated with cleaning the corrugation and its surface. The strength of the elements depends on the material of manufacture, so aluminum pipes are considered too soft, so their shape may be disturbed during careless maintenance and installation.

Key selection criteria

Corrugation metal or plastic for hoods should ideally fit a specific room. When choosing, you need to pay attention to the technical characteristics of the tube, the material from which it is made, as well as its compliance with the parameters of the room and gas column or other equipment.

In addition to these criteria, quality, reliability and cost are equally important. Experts recommend taking into account the diameters of the corrugation itself and the hood, the length of the duct, which should be the smallest of all possible, given the fact that the creases of the tube cannot exceed an angle of 90 degrees.

Installation and assembly

The installation of the duct is usually divided into two stages, including the preparation and conduct of the installation itself. At the preparation stage, the make and size of the tube are selected, as well as all the necessary tools, including an electric drill, screwdriver, hacksaw, pencil and tape measure. The installation sequence consists of several standard steps:

- Make markings before placing the hood and laying the duct.

- In the place where the ventilation duct passes into the kitchen, a wall is drilled to accommodate an adapter or grille.

- An adapter is installed and fixed on this section, on which the air duct will subsequently be attached.

- Next, you need to attach the corrugation to the adapter with a clamp.

- The second end of the duct is put on the outlet from the hood and fixed on it with a clamp.

- Corrugation joints must be sealed with metal tape.

When the length of the tube is longer than necessary for connection, before installing the corrugation to a square or standard hood, it is adjusted using scissors or a hacksaw for metal. Installing the tube on the hood does not cause difficulties if you follow the step by step instructions. Everyone can cope with such an operation without the help of installers and other specialists. Corrugation for the duct must be secured as accurately as possible and in accordance with the rules. You can do the hood yourself after studying the general rules for installation and operation.

A corrugation of 150 mm for the hood or a similar tube of a different size does not cause difficulties during operation. Keep in mind that it is not so easy to clean. If this is not done, over time, a dense coating layer of fumes, dust and grease may form inside the pipe.

Masking corrugations for hoods

In addition to following all the installation rules, you need to take care of the aesthetic appearance of the tube, which can be carefully masked taking into account the characteristics of the interior. Most often this is done with the help of a decorative hood for the hood, if it comes with the kit. If this is not enough, it is better to choose a more optimal option. If there is a built-in type hood, the tube is hidden in wall cabinets or under a false ceiling. In rooms decorated in hi-tech style, a metal pipe can be left in a prominent place, since in this case it will complement the decor well.

Sometimes the duct becomes a logical part of the overall composition and fits perfectly into the interior. In multi-apartment buildings, corrugations can be led out to a ventilation channel in a common home. They are also masked with the help of specially made drywall constructions or closed with a box in whole or in part.

The camouflaged corrugation and the exhaust pipe should work without interruption, therefore, in the process of decoration, it is important not to violate the general rules of installation and operation. After the end of the service life, the old corrugation is changed, so the decor should be such that dismantling can be carried out without completely disassembling the ventilation structure.