Most private sector buildings have basements for storing various products and canned goods. Regardless of the purpose of the basement, arranged below ground level, it is necessary to properly make ventilation, providing fresh air to the cellar. Its presence will create the required microclimate and prevent the formation of dampness, significantly reducing the shelf life of products. In addition, it will protect structural elements from excessive moisture, which gradually destroys the base of the structure.

Types of ventilation

A separate extract for the cellar, like all known ventilation systems, is organized in two ways: natural or forced. Their arrangement differs significantly in the applied structural schemes and in the means invested in them. Natural ventilation in the cellar is done in accordance with a typical project, according to which air enters it due to the temperature difference inside and outside. When applying the second scheme, a pressure-generating element is introduced into its composition, as a rule a fan is usually used.

Features of natural ventilation

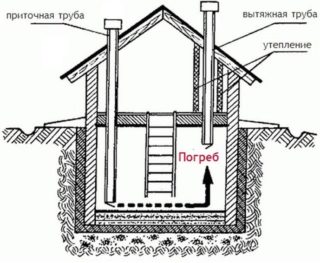

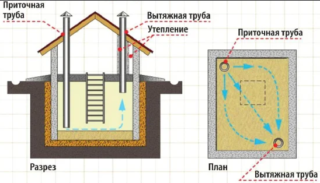

Because there is always a difference in the temperatures of the external and internal environment, a pressure gradient appears at their boundary, causing the movement of air masses. Due to this, fresh air from the street through the intake opening enters the basement and displaces the settled and musty masses through the outlet channel. The main elements of the natural hood include the supply pipe, exhaust duct, exhaust air from the basement and the so-called "vents".

The inlet is equipped with a fine mesh that protects against ingress of dirt, foreign objects and rodents into the pipes, and the outlet is closed with a protective visor. To obtain the required draft ventilation basement is equipped in compliance with the following rules:

- First of all, the problem of creating the maximum difference in height between the inlet and outlet openings is solved.

- You should also try to place them along the longitudinal diagonal of the basement (at opposite ends).

- The inlet is made at the bottom of one of the walls, and the hood is in the upper part of the wall opposite the first.

For laying pipes and ducts of the exhaust system, standardized workpieces of a suitable size are used.

The development of the natural ventilation circuit of basements in private houses in accordance with applicable standards (SNiP) is carried out at the design stage. According to the results of preliminary calculations, the throughput of pipes and ducts is calculated. In this case, the working volume of the serviced basement is necessarily taken into account.

Forced extraction systems

A forced extract in the cellar functions by moving air masses driven by an external device, the function of which is usually performed by a fan. Its main components:

- air ducts along which air masses move;

- a blower unit by which air exchange of the desired intensity is achieved;

- intake devices designed to maintain air circulation;

- mating structures combining air lines with various sizes of pipes and ducts.

Typical examples of the latter are tees used when combining or separating air flows is necessary. They include extension cords and diffusers of various configurations. The forced ventilation system is additionally equipped with the following elements:

- special filters that clean the air pumped from the outside;

- a heating unit designed to heat it;

- temperature control unit, installed depending on the design features of the basement and customer requirements.

The forced draft equipment is prepared according to a pre-compiled scheme. Even at the design stage, the system is calculated, according to the results of which the required air exchange rate is determined and its operation modes are selected.

Due to the expanded functionality, forced ventilation has a number of advantages:

- weather independent;

- the presence of automation that allows you to effectively distribute air flows and choose the optimal temperature regime;

- the possibility of operation in the basement of a large area.

The disadvantages of forced ventilation include significant cash costs associated with the purchase of ventilation and additional equipment, as well as the complexity and high cost of installing the system.

Requirements for the arrangement of the cellar

A competent arrangement of ventilation systems of the underground of apartment buildings is impossible without preliminary calculations carried out in compliance with the requirements of current standards. Only in this case, the efforts made by the builders will be able to bring the expected result.

The main element of ventilation equipment in the basements of public buildings and residential buildings are the air vents arranged at the basement level. The choice of their size and quantity is determined by calculation, with the obligatory taking into account the following factors:

- basement area of an apartment building;

- volume of sewer and plumbing systems;

- the presence of auxiliary equipment emitting harmful fumes.

The intensity of air exchange and the safety of personnel serving basement and semi-basement rooms depend on the correct calculation and installation of vents.

Cellar ventilation recommendations

Before installing any of the described ventilation systems, you will need to familiarize yourself with the recommendations:

- It will be correct if the hood in the cellar is equipped directly during its construction. In this case, when laying the walls, holes are immediately left in which ventilation pipes are subsequently installed.

- It is preferable to choose pipes with the same diameter, which ensures uniform movement of air masses.

- If necessary, to speed up the process of removing the air saturated with dampness from the basement, the exhaust pipe is chosen a little wider than the supply pipe.

It is strictly forbidden to extract an extract from an inflow, since the air in this case will be delayed within the basement. This negatively affects the condition of the products stored in the cellar and threatens the health of a person falling into the gassed space.

Do not place both ventilation pipes next to each other, this prevents good ventilation of the room. They are recommended to be laid along opposite walls and corners. Thanks to this, the fresh air stream before entering the street captures almost the entire space and draws stagnant layers with it.

A hole for the chimney is made directly under the ceiling, since the warm, gassed air rises upward and there is no stagnation.In order to obtain good draft, the exhaust ventilation pipe rises as high as possible (at least 150 cm above the ridge or ceiling ceiling of the cellar). For this part of the ventilation circuit, typical plastic pipes are used, which are used in the arrangement of sewage systems.

If the basement is located directly below the garage or under another business facility, an access hatch is used as an exhaust opening. In this case, you will have to make two doors, one of which is insulated and intended for winter, and the second has a frame structure and is equipped with a grill. The latter is necessary to protect small rodents from entering the basement.

Advantages and disadvantages

The positive aspects of arranging ventilation systems in the basement and in the area of the basement of buildings include:

- guaranteed provision of a comfortable microclimate in the house and the absence of traces of dampness on the ground floor;

- the convenience of using the storage room, in which a stable temperature is maintained, and the moisture content in the air does not exceed the norm;

- extension of the life of wooden supporting structures of residential buildings.

In a ventilated basement, if desired, a simple heating device can be installed and the possibility of accumulation of pathogenic mold spores causing diseases of varying degrees of danger is excluded.

Rules for installing air outlets

The hood in the basement is mounted in accordance with current standards and taking into account the following technical requirements:

- Air ducts are installed in such a way that there are as few sharp turns and bends as possible along the pipe laying route.

- The farther the pipes are located relative to each other, the better the conditions for air circulation throughout the entire volume of the basement.

- The exhaust pipe should be mounted in one of the corners of the basement.

The exhaust duct is recommended to be attached to the ceiling part, taking into account that when laying the final section of the highway was at a height of at least half a meter from the top point of the structure. The supply channel is located on the opposite side at a distance of 0.2-0.4 meters from the foundation base. The optimal conditions for normal natural air exchange are created by pipe lines with a workpiece diameter of 12-15 cm. Their lower part is located near the ceiling (at a height of at least 1.5 meters from the floor), which allows the heated air to fully exit. The air duct from the basement passes through all the upper rooms and is displayed on the roof, where it is installed so that its top rises 1.5 meters above the ridge.

Outdoor mounting

When air masses pass through a pipe section located on the street, condensation builds up inside, and frost can form in winter. This can be avoided if this part of the common duct is well insulated. For this purpose, a larger pipe billet is put on the main structure, and the resulting gap is filled with insulation (mineral wool, for example).

The outlet of the ventilation system must be covered with a fine protective net. It is even better to install a special ventilation deflector on the pipe head, due to which an artificial vacuum is formed around the outlet channel (this helps to increase the draft). If the supply air duct of a system with a deflector is routed through the roof, its intake opening is made at least one meter below the exhaust pipe cut.Only when these conditions are met, is it possible to obtain a significant pressure drop between the inlet and outlet openings, which helps to increase traction and improve the flow of air masses. In combination with the effect obtained through the use of a deflector, this will significantly increase the intensity of air exchange.

Often with the independent arrangement of basement ventilation under a private house, the supply duct is discharged through an opening made in the ceiling or in the bearing wall of the building. In this case, a fine mesh (grille) is necessarily worn on its pipe outside, eliminating the possibility of dust and debris getting into the internal spaces. In addition, it protects the ventilation duct from rodents.

In the interior of the basement, flaps of a special design are mounted in each branch of the duct, opening or closing, which manage to change the intensity of air flows. This ensures the creation of the necessary microclimate necessary for long-term storage of household utensils and canned products.