Properly organized ventilation in a frame house is an important aspect for buildings of this type. Features of the materials from the frame require a special approach to creating a ventilation system. Before installation, you need to study the rules and regulations, choose the appropriate type of system and deal with its nuances. You can also carry out step-by-step installation yourself, following the instructions.

The need for ventilation in the frame house

The walls of buildings made of frame can hold heat indoors well and thereby reduce energy costs. This effect can be achieved through layer-by-layer laying of the insulation, the use of materials with vapor barrier, parts of internal and external decoration. The economy of this type has its drawbacks, it provokes an increase in the humidity level in the room, as well as incomplete removal of the exhaust air from there.

The protective layer of the vapor barrier is able to hold the condensate remaining inside the walls, accumulating it can ruin the insulation, finish and frame, which begin to decay. The ventilation system in houses of this type is also necessary in order to prevent the accumulation of chemical vapors by which the frame bars, bindings and other elements are treated indoors. They are impregnated with special antiseptics from rodents and insects.

Ventilation in a Finnish house

When building according to Finnish technology, a heater with a thickness of up to 100 mm is laid inside a frame of wood. After that, the frame is sheathed with timber from the outside and inside. This technology is not widely used in Russia due to the lack of necessary protective materials for hydro and vapor barrier. Ventilation in the Finnish house should be clearly organized, otherwise condensation will begin to accumulate inside the walls, which will render them unusable. Without moisture protection, seals quickly grow into fungi and mold. The presence of even the simplest ventilation system helps to improve the microclimate inside the frame Finnish house.

Norms and Requirements

Installation of ventilation systems in private homes should be carried out taking into account the sanitary requirements of GOST 30494-2011. It takes into account indicators such as air temperature, including the total, its speed of movement and the proportion of humidity. Depending on the specified standards, it is necessary to use acceptable or optimal indicators in the calculations, all of them are presented in Table 1 of the GOST.

In living rooms, the temperature can vary between 18-24 degrees, the percentage of humidity should be no more than 60%, and the speed of movement of air masses is 0.2 m / s.

For the kitchen and the bathroom, these indicators are 18-26 degrees and 0.2 m / s., The norms of relative humidity in such rooms are not critical. Proper ventilation in any frame house is mounted including by the standards of the joint venture. To avoid condensation, air ducts are thermally insulated taking into account SP 61.13330. To protect the walls inside and out, use special anti-corrosion materials or compounds. Installation and adjustment work must be carried out according to the standards of SP 73.13330, this applies to ventilation systems of any type.

The main types of ventilation

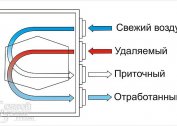

Ventilation in a frame house can be one of the most common types, depending on the purpose. Systems are divided into several subgroups, taking into account the direction of movement of the air masses, the territory of service, as well as other factors. They can be supply or exhaust, with natural or mechanical motivation, general exchange or local.

Natural

This type of ventilation is considered the most popular, in this scheme the air masses are set in motion due to the difference in pressure between the external and internal atmosphere. For this system to work, it is necessary that street pressure be lower than indoor pressure, after which air will begin to move through the ventilation ducts. Such channels are installed in the walls of multi-storey and private houses. The main advantage of standard ventilation is the low cost, since the installation of the system does not require large expenses.

It is necessary to take into account the dependence of such ventilation on atmospheric parameters. Since the movement in the channels can occur only with a negative pressure difference, if the pressure is equalized, the air exchange is automatically interrupted.

The natural ventilation system is highly responsive to changing weather and rainfall. On frosty days, the draft can be several times less than the calculated one, while in autumn, the movement of air from the outside begins to affect the interior.

Forced

In forced ventilation systems, the movement of air is carried out due to electric energy with the help of fans and units of supply or exhaust type. The main driving element of such a system is a fan, consisting of a body part, an impeller and an electric motor. An electric motor stimulates the movement of the impeller, made taking into account the capture of air flows and their movement from the intake openings to the exhaust.

Fans can be centrifugal or axial; in the first, air moves parallel to the blades, and in the second, it passes through the impeller. In addition to the fan, additional elements are used in forced systems: valves, air flow regulators, filters for cleaning, silencers, air heaters, diffusers, air dampers, grilles, clamps, heaters and other devices in combination with other installation materials.

Combined

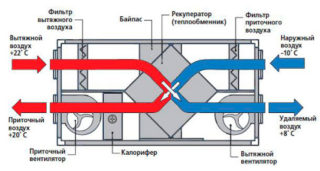

The list of the most popular combined systems includes ventilation of the supply and exhaust type with recovery. It helps to save energy resources during operation, since the inflow and exhaust are built into one device that moves both the supply and exhaust air. Two branches need to be placed in one device in order to move airflows, recuperators are installed at the intersection points, which transfer heat to the supply air from the exhaust air. In some cases, such systems can save up to 80% of heat and return it back to the room. For them rotary or plate recuperators are used.

Features and ready-made schemes

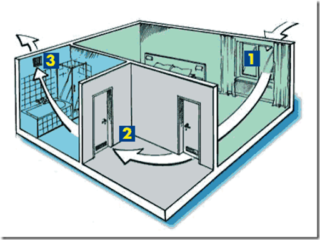

Choosing a specific type of ventilation for a frame house is necessary taking into account financial capabilities, the number of residents and the area of the room as a whole. Due to the non-standard structure, installation of ventilation ducts in a frame house is possible inside ceilings and walls. In some house projects, special openings for the necessary communications are provided in advance. These are exhaust ducts in which fans can be placed, mounting them in the kitchen or in the bathroom, where high humidity is maintained.

The list of available schemes includes primitive forced ventilation, exhaust and supply systems, organized and unorganized ventilation options.

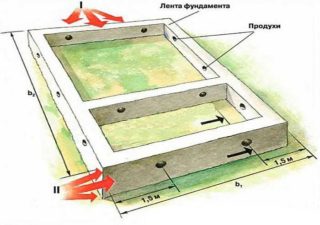

Underground ventilation

Due to the design features of frame houses, there should be free space between the ceilings of the first floor and the ground, while it is impossible to equip basements in such buildings. To prevent the accumulation of dampness under the floor and the destruction of the foundation, special openings are formed inside the basement - vents. They help to ventilate underground rooms and normalize their moisture balance. With their help, mold, fungi and other microorganisms can be eliminated. A special frame home floor ventilation shaft is also included in the overall air exchange of the entire house.

Step-by-step installation instructions

You can make ventilation in a frame house with your own hands without the use of special expensive equipment. The installation of the system is carried out in stages using several sequential steps:

- Supply air valves are equipped by drilling holes in the walls and floor with the desired diameter.

- An air duct pipe is inserted into each of them, supplemented by a grill on the outside and a duct fan on the inside.

- All joints are filled with polyurethane foam, after it hardens in the necessary places, they put an air filter and sound-absorbing equipment.

- After installing the supply valves, the channel layout is established, sealing all their fasteners and joints.

- After sewing up the channels inside the box and installing the decorative finish, the system is checked.

To make a high-quality ventilation system with an exhaust hood, it is advisable to develop its scheme and design in advance. It provides for the installation of elements on the facade, roof and attic, taking into account the characteristics of a particular structure.