It is difficult to manage well-functioning and reliably functioning ventilation both in production and in everyday life. It allows you to regularly update the air in the premises of factory floors and in apartment buildings, significantly increasing the comfort of staying in them. There are two ways to organize effective air exchange: natural and forced ventilation. Of particular interest is the second of these options.

What is forced ventilation?

By ventilation in general is meant an intentionally created system of air renewal, implemented by replacing the waste mass with new, supply. In contrast to the natural process caused by the difference in temperature (pressure) inside and outside the building, a forced ventilation system needs a special propulsion. An electric fan is usually used as the latter.

An additional element leads to the fact that the work on the arrangement of forced ventilation in the apartment is also complicated. In this case, a careful calculation of all elements of the system, tied to the characteristics of the serviced object, is necessary. In preparation for the independent design of the ventilation complex, the following points are taken into account:

- the choice of ducts suitable for placement within a house or apartment;

- drawing up a wiring diagram for their wiring;

- purchase of a fan of the required power.

Only after solving all these issues can you proceed directly to the installation work.

Features and device

The device of the forced exchange system is quite complex, since it, in addition to air ducts and a fan, includes the following mandatory elements:

- air intake grilles mounted on the outside and protecting the air ducts from the ingress of mice, insects and small debris;

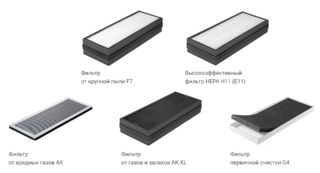

- purification filter system;

- air valves;

- heaters and sound absorbers;

- automation that controls the operation of all elements of the system.

Filters clean incoming air masses from contaminants (dust, fluff and microparticles), and air valves are needed to adjust the strength of the flow coming from the outside. In cold weather, they isolate the system from strong gusts of wind. Sound absorbers ensure silent operation of forced exhaust ventilation, and air heaters regulate the supply air temperature in winter.

Advantages and disadvantages

The benefits of forced ventilation include:

- independence from weather conditions and guaranteed inflow of fresh and exhaust air;

- the ability to change operating modes by fine-tuning them;

- providing the system with air purified from impurities, dust and microorganisms;

- admissibility of heating of incoming air masses in winter.

It is also important to note the possibility of using the recovery effect in forced systems, which reduces the cost of heating and heating the premises. These advantages do not exclude the presence of disadvantages of this ventilation method. Forced hood has the following disadvantages:

- high costs for arranging the system;

- the complexity of design, installation and subsequent maintenance;

- the need for regular technical inspection of the system and routine maintenance (including the replacement of worn elements);

- increased noise in rooms during the operation of ventilation.

In addition, the dependence on power supply is considered a drawback of these systems.

The main types of forced ventilation

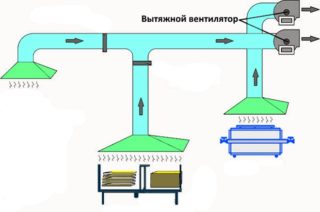

By the method of organizing air circulation, forced ventilation is conditionally divided into the following three types:

- supply;

- exhaust;

- supply and exhaust.

In the first case, the fan is installed in the air intake channel (such a scheme is used in the bathroom, for example), and in the second - in the exhaust pipe. The third option is considered as a combination of the first two, when the ventilation device is installed in both channels at once. Each of the varieties is able to solve a certain range of problems associated with the characteristics of the operation of various rooms.

Forced ventilation is most often equipped in the bathroom, combined with the toilet, or in the kitchen. To do this, a powerful fan is mounted in the ventilation shaft, which goes into the toilet, and a typical hood is made in the kitchen room, which ensures the removal of exhaust air.

Regardless of the selected ventilation ducts scheme, it is recommended that you consult with specialists before starting work.

Features of installation of forced ventilation

Self-installation of ventilation is associated with many errors that it is desirable to exclude in advance. Even at the stage of project preparation, you should decide which rooms will be involved and mark the routes for laying ducts. When doing independent work, it is important to consider the following installation features:

- Bolt fasteners on brackets are tightened against the stop.

- The use of rubber gaskets (vibration isolation elements) is mandatory on fasteners. They are selected taking into account the mass of the boxes and guarantee a reduction in the level of vibration (the latter are not transmitted to working units).

- Fans are mounted on a pre-prepared base at the final stage of work. To fix them, rigid supports are used, on which they are mounted with anchor bolts.

- The filter elements are mounted without sagging.

- Motors are installed as close to the fans as possible (close to them).

Regulatory requirements prescribe the use of special grilles that close the supply and outlet windows of the holes. Cell sizes should not exceed 7 cm. It is also important to ensure that the number of turns and bends of the ducts is minimal. Otherwise, increase fan power.

Installation Care

Do-it-yourself ventilation will serve the owners for many years if its prevention is timely carried out. Care of ventilation equipment depends on its composition and location. In expensive cooker hoods, for example, filters will need to be changed periodically, and servicing budget models comes down to washing them under warm water.

To avoid fan breakdowns, they should be cleaned from dust deposits and small particles of debris at least once a month. Bolted joints are periodically checked for strength and tightened if necessary. Competent and timely maintenance of ventilation equipment is a reliable guarantee of long service life.