Problems with poor draft in the chimney become less if a turbo deflector is used for ventilation. The device normalizes air exchange. The cost pays off in the first year of work due to energy savings. Constant rotation of the rotation head eliminates the occurrence of reverse thrust. The turbo deflector is used in ventilation installations and systems for the removal of combustion products.

Definition of a turbo deflector

The deflector is an aerodynamic structure that is mounted above the chimney. The device uses the Bernoulli principle. The effect is that the static pressure in the channel decreases with an increase in the speed of air movement and a change in the transverse area of the pipe. Ventilation turbo reflectors increase traction and increase the efficiency of the outlet channel.

Use common designs:

- classical in shape - rectangular, square, round;

- tsags - nozzles have a screen in the form of a cylinder, where a deflector of a conical shape is located;

- Grigorovich - a common version is placed on the nozzle in the form of a truncated cone, such a model is often made with your own hands;

- rotational - has a spherical overlay, contains a turbine and blades in the structure;

- n-shaped, double - is made in the form of two perpendicular tubes connected by a hollow jumper where the exhaust pipe is connected.

Static models are installed in the common channels of multi-storey buildings and individual ventilation systems; they are used to coordinate smoke extraction in heating circuits and ventilate garbage chutes.

Design and principle of operation

The device uses the wind to dilute the atmosphere in the ventilation shaft and accelerates the removal of the polluted stream. The principle of operation of the turbo deflector is that a change in the force and direction of the cyclone does not affect the efficiency of operation, because the impeller always turns in one direction and evacuates the shaft space.

The design includes 2 parts:

- The top is represented by a rotating head, the movement of which is given by the wind due to pressure on the blades. The head is mounted with bearings, with a characteristic of zero resistance. The blades rotate on roller bearings, the movement will be uniform with a small and strong wind.

- The bottom is made in the form of a base, fixed to the tip of the chimney pipe. In the case there are openings for hardware. The kit includes roof passages at an angle of 15 - 35 ° by order of the buyer.

The intensity of the air flow eliminates tipping over the draft, and the cap above the pipe protects against debris and rain.

Pros and cons of turbo deflectors for ventilation

Devices help increase air exchange, prevent the appearance of condensation in the space between the elements of the roof.

The exhaust fan turbofan has the following advantages:

- does not require connection to electricity;

- It has a long service life, depending on the material it works from 10 to 15 years;

- the channels where the rotary deflector stands are less often cleaned due to the exclusion of accidental hit of objects;

- compact and lightweight devices do not exert pressure on the pipe;

- installation does not require special skills;

- the equipment almost does not freeze in frost due to constant mobility.

There are some disadvantages to using a turbo deflector. Due to the strong draft in the channel, the burners of the gas boiler are sometimes blown out. The turbine stops in completely calm weather, with increased relative humidity to the limit or severe frosts.

Equipment cannot be used as the main forced device in systems that serve rooms with increased cleaning requirements (laboratories, some industries).

Types of turbo deflectors

Many types of deflectors have been developed to select a rotary head model that works effectively in specific conditions. All devices differ in technical characteristics, despite the fact that commercially available options almost do not differ in appearance.

Models of rotational turbines differ:

- on the material of spare parts;

- by the size of the connecting ring.

Moving parts require periodic maintenance. The cost of turbo deflectors is quite high, so many owners can make and install the design with their own hands.

According to the material of manufacture

The choice of material depends on the preferences and budget of the buyer. Some parts of the turbocharged device are made of plastic. Organic material based on natural or synthetic polymers do not respond to moisture, acid precipitation.

The main materials are:

- thin sheets of chrome or galvanized steel with a matte finish are presented in budget options;

- stainless steel has a double cost compared to the previous material, powder painted in standard colors of roofing;

- structural metal with a polymer coating does not differ in color from the facade or roof of the building.

Steel is a combination of carbon and iron, the first element gives the alloy hardness and strength, but reduces viscosity and ductility. Hot dip galvanizing is used to prevent surface corrosion and is a reliable method of protection.

Chrome plating saturates the surface of steels with chromium molecules in an electric current or in an electrolyte bath. Processing increases the resistance of metal to destruction and improves the appearance of products. Stainless steel is used without coating or with a decorative layer, actively resists corrosion due to the addition of chromium, phosphorus, nickel, copper in the production.

By the diameter of the connecting ring

The size of the seat is indicated in the labeling and passport of the product. The diameter increment is 5 mm; sizes from 100 to 200 mm are available. Over 200 mm, sizes 250, 300, 315, 355, 400, 500, 600, 680 and 800 are made. Turbine diameters for drawing 1000 mm and others are made to order.

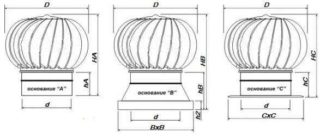

The deflector is installed on the output section of the ventilation pipe, which may have a different cross-sectional shape. Devices are available with a round, square base. There are turbo-deflectors with a box-shaped base of the transitional type. They are installed on ventilation ducts made of bricks or blocks.

The turbine maintains operational efficiency if the cross-sectional area of the seat ring differs with the same pipe parameter by no more than 15%.

Application area

The rotary nozzle on the head of the ventilation shaft is intended for rooms that require accelerated air exchange. The device has proven itself as part of the smoke exhaust system for heating buildings.

Turbo deflector is used:

- In houses of a multi-storey sector and private buildings.The device increases traction in the ventilation ducts of the last floors, eliminates the risk of reverse traction. In their own homes, the deflector is installed to ventilate cellars, pantries, food storages, and is used for chimneys.

- On farms in livestock and agricultural buildings. They equip the mine risers of poultry houses, stables, hayloft, grain storage.

- In environmentally friendly industries and in processing workshops.

- In public halls and crowded places, for example, sports complexes, shopping areas, theaters, etc.

The unit is used to ventilate the attic floors and ventilate the roof space. For this, a device is used with a diameter of the lower part 315 - 355 mm, which captures a plot of 50 - 80 m2. The size of the ventilated area of the attic depends on the slope of the roof and increases with the steepness of the slope. A fireplace hood will work more efficiently when using a rotary deflector.

Installation and Maintenance

Turbines to enhance traction are placed on a straight and pitched roof, mounted on the exit of the chimney or pipe. On the pitched roof, the highest point is selected, and the calculation of the height of the ventilation outlet is carried out taking into account the size of the deflector. Installation is not difficult, so you can install a turbo deflector for ventilation with your crayfish. Maintenance includes lubricating the roller bearings and checking the blade mobility.

Turbines to enhance traction are placed on a straight and pitched roof, mounted on the exit of the chimney or pipe. On the pitched roof, the highest point is selected, and the calculation of the height of the ventilation outlet is carried out taking into account the size of the deflector. Installation is not difficult, so you can install a turbo deflector for ventilation with your crayfish. Maintenance includes lubricating the roller bearings and checking the blade mobility.

Reasons for stopping the impeller:

- lack of wind currents;

- seized bearings due to mechanical obstruction or lack of lubrication;

- freezing mechanism.

Frequent maintenance is not required, once a year it is enough to check the condition of the device and climb the roof in case of a stop. In the process of lubrication, the cap is removed, the snap ring is disconnected using a puller. So the bearing is replaced.

DIY turbo deflector

There are 2 options for a homemade turbo deflector, which is easily constructed with your own hands. In the first case, the body is made of a metal container in the shape of a cylinder. The blades are cut out of the walls, they need to be bent outward. A housing is mounted on the rotary axis without the use of bearings. The base is made of a piece of metal pipe of suitable diameter. The unit is attached to the ventilation outlet with a clamp. The design is inferior in appearance to factory models, so it is placed on outbuildings.

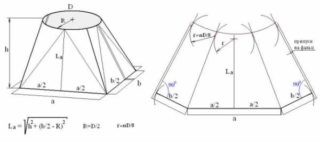

The second option is done using a drawing of a turbo deflector, which is transferred to cardboard, the details are cut with scissors. Parts are transferred to metal using ready-made patterns. Before bonding with each other, fitting and fitting is done. For connection, self-tapping screws, bolts with nuts and metal strips are used. The diameter of the ring is measured at the installation site, the shaft and sleeve are made of one metal.

Blueprints

First, the need is calculated, then drawings are made, which can be downloaded on the Internet. Drawing matters if the number of sheet steel is limited. So the details will be compact and no extra area will be wasted. Cut parts are mock-up to verify dimensional accuracy.

Calculate the need for a device by the formula N = V / Pwhere:

- N - number of deflectors;

- V - ventilated volume;

- P - device performance (is in the technical passport).

The ventilated volume is calculated by multiplying the volume of the room by the required air exchange.

Turbo Deflector Selection

If weak thrust is detected, it is better to choose turbocharged types, as static installations will not cope with the task. It is better to buy a mechanism with a closed bearing system. In budget models, open hinges are often used, which are faster covered with ice.

Selection options:

- the diameter of the outlet of the chimney or ventilation shaft;

- by sectional area of the duct.

If the deflector is installed on the roof without ventilation outlets, the number is calculated according to performance taking into account the volume of the under-roof space. In areas with regular strong winds, an H-shaped deflector works well.

Turbovent enterprise makes aluminum turbines, the thickness of the metal is 0.5 - 1 mm. For the base, galvanized steel sheets of 0.7 - 0.9 mm are used. For painting, the RAL catalog is used. Manufacturer Turbomax produces natural traction amplifiers from 0.5 mm AISI 321 steel. The product withstands temperatures up to + 250 ° C, therefore it is placed in chimneys from furnaces.