Equipping the house with ventilation is one of the most important conditions for ensuring a microclimate that is comfortable for living. Such a system allows fresh air to enter the room, while taking the used air out.

In the summer, when the air conditioner is installed in the house, the very heated air supplied from the ventilation duct reduces the efficiency of such equipment. In winter, heat is also vented through ventilation ducts with air. All this at any time of the year leads to an increase in material costs - for electricity and heating the house.

In order not to waste material resources, successfully solving such problems, an air recuperator for a house or apartment began to be used.

What is a recuperator

A recuperator is a special type of equipment that ensures the removal of used air from the house, filling it with fresh air at the same time. A heat exchanger is installed inside such a device, using heat from the room, which the recuperator gives off to fresh air currents, heating them in this way.

The principle of operation of this type of equipment is quite simple: it is a conventional heat exchanger, inside which, without mixing, two air flows pass from the supply air street and from the exhaust room. As a result of different temperatures of these flows, thermal energy is redistributed between them. In this case, the temperature of warm air decreases, and cold air increases. In addition, the cooling process also removes excess moisture that settles on the heat exchanger.

At its core, the recovery process is one way to reduce heat loss through ventilation ducts. That is, this is one of the technologies of energy conservation.

The presence of a recuperator in the house helps to save up to 70% of the heat leaving the street. Nowadays, such equipment is distinguished by its design and power.

Basically, a recuperator is used to reduce material costs for heating a house. So, thanks to the presence of such a device inside the room from the street, fresh air does not come in cold, but already heated.

The economic benefits of installing such equipment are more tangible first of all for owners of private houses who themselves heat their own housing. In apartment buildings, where a central heating system is installed, such savings do not justify themselves. In such dwellings, it is more important to provide the house with fresh air from the ventilation system. The installation of a recuperator also successfully solves such problems.

Recuperator classification

There are several classifications of recuperators, according to which they differ from each other. Among these classifications:

Depending on the movement of the used coolant inside the device:

- counterflow type;

- direct-flow type.

Depending on the design features:

- ribbed;

- coaxial or tubular;

- lamellar.

From the destination - for heating:

- air;

- water or other liquids;

- different types of gases.

Rotary Type Recuperator

The most widespread in modern homes are two types of such equipment - rotary and lamellar. Let's consider them in more detail.

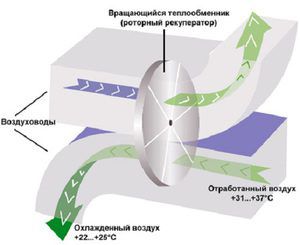

The rotary air recuperator is a metal cylinder in which there are a large number of layers of corrugated steel. They are located longitudinally.

With the passage of air, the drum of the device begins to rotate, passing in turn warm and cold air. In this case, the plates are cooled and heated, and heat is transferred from the heated air to the cold.

A recuperator of this kind is notable for its considerable work efficiency, however it is rather cumbersome. To install it requires a spacious ventilation duct.

Lamellar recuperators

The plate air recuperator has the form of a cartridge, where the channels through which the incoming and outgoing air moves are separated by sheets of galvanized steel. Due to this separation, the air flows are not mixed, heat exchange is carried out as a result of simultaneous cooling and heating of the plates on both sides.

Due to their compact size and low cost, plate heat exchangers are widely used in private homes. However, when using such equipment, there is a possibility of freezing of the heat exchanger in the case when the temperature in the street is too low. This is due to condensation forming on the outside of the ventilation duct.

The efficiency of devices of this type is characterized by its efficiency, which reaches 60%. Another important advantage is the simple design of the heat exchanger: it does not have any moving or rubbing parts, it does not require electricity.

Along with the advantages, there are some disadvantages:

- freezing of the outer part in severe frosts;

- the design should be the intersection of pipes along which air flows.

Despite this, it is this type of energy-saving equipment that is most often used for the home.

Together with the factory equipment, homemade devices are also very common, which are not very difficult to make yourself.

Preparation for production and materials

By making a plate air recuperator with your own hands, the most important thing is to make a heat exchanger in a quality manner. In this case, it will be possible to save up to 60% of the heat.

To do this, you will need the following tools:

- pliers and a hammer;

- angle grinder;

- hacksaw for cutting metal;

- corner, tape measure and drill.

Before starting work, it is extremely important to correctly create a drawing of a future recuperator, where the dimensions of the main components of the device must be precisely determined. And after that it will be possible to start preparing all the necessary materials and getting started.

Making a recuperator yourself, you will need such materials:

- roofing sheet metal with a galvanized surface or other flat material;

- textolite;

- plastic flanges, the diameter of which corresponds to the diameter of the duct pipes;

- a wooden beam with which the metal base will be fixed in the duct of the ventilation system;

- insulation, silicone and sealant.

Work sequence

When all the tools and materials are ready, you can start making a recuperator with your own hands.

First of all, a small box is made of sheet metal, its walls are insulated from the outside with polystyrene or other similar material. Instead of metal, you can also use a box made of MDF. To install pipes for air flow in the walls of the box, you need to make holes of the corresponding diameter.

From tin or some other thin metal, small rectangular plates are cut, which must be installed in parallel with each other. Their dimensions should be slightly smaller than the internal dimensions of the box. In this case, a technical plug can be used as a filler and bearing elements.

In order to prevent warm and cold from flowing together during the passage of air currents, metal plates are installed so that cavities for air supply and exhaust with displacement are obtained. As a result of this, the exhaust air will pass from the bottom up, and the supplied air from left to right.

When such a design is ready, it is placed inside the box, all the cracks and excess holes are hermetically sealed with silicone. As a result of this, a self-made recuperator will be ready, it is installed in a ventilation shaft. It remains only to connect the intake and supply ducts to the device pipes, after which the ventilation system device with a recuperator will be ready.

Thus, in your home you can use both factory and home-made air recuperators. Since the cost of ready-made models is quite high, many craftsmen prefer to make such devices with their own hands, since with the appropriate skills to do this is quite realistic.