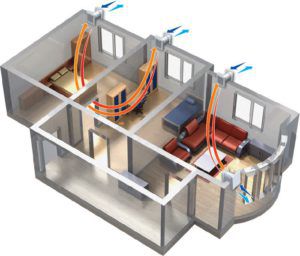

A well-thought-out ventilation system is one of the prerequisites for a comfortable stay in any room. By means of the ventilation system, the optimal microclimate of the room is provided, suitable for both temporary residence and for permanent residence of any number of people. Special requirements in the process of restoring ventilation are presented to kitchen rooms and rooms with high humidity (bath, shower, sauna and others). Within the premises of this type, a mass of not just undesirable particles is formed, but substances and formations that are harmful enough to human health. For example, molds and excessive accumulation of moisture in the bathroom, soot, soot, settled fat, often formed on the surface of the kitchen. Properly planned ventilation, erected within the premises through the use of plastic ventilation ducts, can get rid of the consequences of such unpleasant phenomena.

Plastic ventilation system in the kitchen

Installation of ventilation ducts copes with all undesirable manifestations and consequences in the process of cooking and the functioning of household appliances. Kitchen ventilation, built in the form of air ducts, is a certain structured structure. Modern channels made of plastic materials are able to provide not only functions to eliminate exhaust air and clean intake, but also perfectly complement the overall interior of any kitchen, regardless of its style.

From this point of view, preference is given to metal air ducts in production-type rooms, and it is preferable to install a duct ventilation system made of plastic in residential premises (houses, apartments).

Base material for the production of channels

The basis for the production of ducts for ventilation systems is plastic. Plastic is a specific synthetic material based on high-tech polymers (high molecular weight compounds).

Modern ducts made of plastic, suitable for use in domestic and small industrial premises, are made of the following materials:

- polyethylene;

- fiberglass;

- metal plastic;

- polyurethane;

- polypropylene;

- PVC

- silicone.

Channel categories for ventilation systems

Absolutely all duct ducts are divided into two categories of manufactured products:

- the basis of the design is high-strength metal;

- air duct design is made on the basis of plastic elements.

Speaking about plastic products, it should be noted that structures made of polyvinyl chloride or simply PVC are most in demand. Products made of PVC differ:

- light or middle class finished products;

- have increased resistance to UV radiation;

- absolutely harmless to human health;

- do not harm the environment;

- differ in the increased tightness;

- easy and convenient to mount;

- unpretentious care during operation.

An effective ventilation system, in particular a cooker hood, can be built using two types of structures: a round and rectangular duct system made of plastic.

Features of a rectangular duct for drawing

In a residential modern kitchen, it is simply necessary to organize a system of reliable ventilation and air exchange. Today, without a powerful hood within the kitchen, it is impossible to imagine a cozy and safe environment. For example, if single-engine exhaust hoods are taken as the basis for kitchen ventilation, then rectangular channels should be mounted, which are characterized by a cross section of 110 X 53 mm.

If the cooker hood has an increased capacity (about 1,000 m3 per hour), then the construction of plastic rectangular channels with a cross section of 220 X 90 mm will be an ideal solution for installation.

Advantages of plastic duct ducts of rectangular type:

- ensuring effective air circulation, continuous air exchange in the room;

- the presence of simple plug systems, with the obligatory fitting of the connections;

- products in this category do not contain cadmium;

- characterized by increased parameters of impact resistance and wear resistance during operation.

- Differ in low indicators of fusibility and ignition;

- The latest air ducts are equipped with a system of adapters, adapters and other related elements;

- The service life of such structures is guaranteed to be about 50 years.

Round ducts made of plastic

A distinctive feature of such ducts are improved aerodynamics. Compared to a rectangular channel ventilation system:

- get tired of the issue of aesthetics and compactness of placement within a landscaped room;

- the round ducts of the duct take up a bit more space and slightly outperform their rectangular counterparts.

The plastic ducts of round ventilation systems are characterized by the least resistance compared to the same rectangular structures. That is why the round channel duct system is recognized as the most effective. But round channels are inferior in external aesthetics. They give priority to rectangular channels, the location of which is permissible not only along walls and any other surfaces, but also over kitchen furniture, in upper cabinets, under ceiling ceilings.

Round ducted PVC ducts are an ideal tool for organizing a ventilation system within small and medium-sized rooms, including industrial, residential, office and commercial.

In general, all the qualitative characteristics inherent in rectangular channel elements also exist in the description of round ventilation ducts.

Features of connections of air duct elements

The process of aerodynamics in both a rectangular and a circular duct channel exceeds the values obtained during the operation of the duct ventilation system of metal structures. Convenience and reliability when using differs literally at times. This fact is explained by the technology used in the production. An important role is played by basic materials based on polymers. Speaking of plastic ventilation ducts, their increased hygiene throughout the entire service life should be noted. This factor is decisive when choosing constructions of this category for installation within domestic kitchens. This is explained by the following: at one of the production stages, the processing of polymers with special compositions is carried out, which provides a further exception for the deposition and accumulation of dust and other contaminants. Therefore, such a system does not need frequent cleaning and disinfecting measures.

Applications for duct ducts made of plastic

Round and rectangular ducted duct elements are in high demand in providing rooms with ventilation systems, regardless of the functional features and purpose of the equipped areas. Such objects may be:

- restaurants, cafes, bars, hotel complexes;

- private houses of various sizes and storeys, country cottages, city apartments within apartment buildings;

- large-scale shopping and business centers, entertainment facilities, cinemas, malls;

- production shops, industrial halls.

Plastic ducts are practically not susceptible to corrosion damage, which compares them favorably with metal products. Given that plastic ducts are much cheaper than ducted metal ducts, their advantages and practicality become obvious to any potential buyer, regardless of the particularities of the planned work.