The purpose of home improvement with ventilation systems is to ensure constant air exchange in all rooms. The use of ducts made of special stainless steel is predetermined by their versatility and reliability. Due to the technical characteristics of these devices, it is possible to use them in all areas of industrial production, chemically aggressive environments, at sufficiently high temperature loads, as well as domestic conditions.

At its core, these devices are a kind of system consisting of metal pipes that serve for such purposes as:

At its core, these devices are a kind of system consisting of metal pipes that serve for such purposes as:

- conclusion of the fulfilled polluted or smoked air;

- the intake of fresh clean air into the room;

- cooling, heating or its purification.

Such ventilation devices are recognized as the most durable, efficient. Pipes for ventilation in these systems are used from stainless steel. This gives them resistance to corrosion, the influence of chemical aggressive materials. Such products have a higher temperature resistance.

They are usually made with a round or rectangular cross section. If these pipes are additionally treated with mineral wool, then their fire resistance can be ensured for the purpose of use in all areas with elevated exposure temperatures. Stainless steel devices remain unharmed even in wet or acid-base environments.

Stainless Steel Duct Specifications

The characteristics of air exchange devices are usually laid when designing a ventilation system, taking into account the ventilated area, its purpose. Moreover, the cross section of the pipeline, as well as the length of its channel are the calculated values.

Devices for ventilation of premises must comply with such characteristics as:

- complete tightness;

- silent operation (allowable noise no more than 25-35 dB);

- speed, air direction;

- resistance to corrosion;

- compactness, light weight;

- Fire safety.

Stainless steel is considered a complex alloy with high anticorrosion resistance to aggressive environments and various weather conditions. Its main alloying element is chrome, which significantly increases its corrosion resistance.

Such stainless steel pipes for ventilation devices are installed inside houses or industrial premises. They distribute incoming fresh air, remove contaminated. The performance of these products depends on such parameters as:

Such stainless steel pipes for ventilation devices are installed inside houses or industrial premises. They distribute incoming fresh air, remove contaminated. The performance of these products depends on such parameters as:

- cross-sectional area;

- rigidity;

- sectional shape.

The main indicator of the technical characteristics of this equipment is its resistance to corrosion, due to the quality of the metal used. The substances included in its composition are indicated by generally accepted standard codes. The most common stainless steel composition has the American Iron and Steel Institute standard, abbreviated AISI. Moreover, for the production of ventilation products of various types of sections (round, rectangular), various grades of stainless steel alloys are used, depending on the conditions and the complexity of their operation.

Attention. It is very important that the device itself, as well as its fittings, have the same steel grade. The thickness of the metal of these products should have 0.5-2mm, and the bevel is 1mm thicker. The walls of the pipes are usually thick-walled so that not only dust, dirty smoky air, but even the smallest particles of garbage can freely move along them.

Scope of application

Ducts are the main component of any ventilation systems. Their round and rectangular channels are designed to transport air or gas mixtures.

Ducts are the main component of any ventilation systems. Their round and rectangular channels are designed to transport air or gas mixtures.

Moreover, round devices are more widely used in all industrial, residential facilities. They are distinguished by excellent tightness, good speed of air flow.

Rectangular products are often used to equip ventilation of industrial, industrial premises with limited space.

The areas where stainless steel ducts are used are very diverse. It:

- chemical, pulp industrial enterprises;

- food, pharmaceutical industry;

- medicine, catering;

- boiler rooms, laundries;

- household premises.

Classification

Ventilation pipes for exhaust devices differ among themselves:

- by sectional shape;

- chemical composition;

- according to the method of their manufacture.

By sectional shape

By their type, stainless steel products come in round, rectangular cross-sectional shapes.

By their type, stainless steel products come in round, rectangular cross-sectional shapes.

Round ducts made of stainless steel are more rigid, and therefore more durable. In the manufacture of them usually takes 25% less metal than rectangular products. This has a positive effect on their lower cost.

Rectangular devices are more practical, have several advantages:

- they can be used on very large areas;

- convenient to carry out installation even under difficult conditions.

Important. Designs with a circular cross-section are well used for ventilation of rooms with a chemically aggressive environment, and products with a rectangular cross-section are more suitable for cleaning the smoky air of boiler rooms, heating stations, and rooms with high temperature conditions.

According to the chemical composition of the material

Varieties of ventilation products depend on the quality and chemical composition of the stainless steel from which they are made. Distinguish:

- nickel chromium;

- chromium, with the best anti-corrosion properties;

- chromium-manganese, nickel.

The most common markings of such steel:

- AISI 430, with low carbon content, is a type of ferritic steel, characterized by low cost, excellent resistance to corrosion, strength, resistance to elevated temperatures.

- AISI 304 contains a moderate amount of carbon, which gives products significant heat resistance, hardness, the ability to use under conditions of high humidity, acid-base atmosphere, easily lends itself to welding.

- AISI 316 contains molybdenum which is especially resistant to corrosion.

- AISI 321 incorporates a high content of nickel and chromium (up to 33%). It is resistant to any kind of corrosion, has increased ductility, strength, and perfectly lends itself to the pressure treatment process.

Ducts are also used in high humidity, environments with acid-base contents, where heat resistance and corrosion resistance are required.

By production method

By the manufacturing method, such devices are distinguished:

By the manufacturing method, such devices are distinguished:

- Spiral welded stainless steel products are produced using special steel tapes, coiled. The resulting spiral is stretched in opposite directions, then its elements are brewed together. Products of this type of steel lend themselves perfectly to the creation, if necessary, of welded joints.

- Long-seam products are made by means of steel sheets formed into solid pipes with a straight seam on special bending machines. All seams then roll well.

- Spiral-locking devices, when a steel strip is twisted with a spiral, at the ends of which a lock is formed in a special way, which is closed with a strong seam on a special machine.

- Corrugated ventilation systems are made of special foil having a thickness of 0.12-1 mm.The strips of such foil are fastened with a locking method, and the seams are fixed with a special spring.

Advantages and disadvantages of stainless steel ducts

First of all, we note the advantages of stainless steel used for these products, namely:

- the possibility of its use in chlorides, alkaline solutions;

- resistance to various temperature differences;

- increased resistance to corrosion;

- ease of processing during welding, cutting, molding;

- strength, deformation immunity;

- attractiveness, aesthetics of the surface.

Duct advantages:

- stiffness, heat resistance;

- heat resistance (withstanding temperatures up to 900 ° C);

- wear resistance;

- high heat capacity, can be used for fireplaces, stoves, boiler rooms;

- moisture resistance, non-susceptibility to mold, mildew.

In addition, stainless steel pipes for ventilation have a polished surface on which soot, dust and greasy sediments do not linger. Stainless steel alloys can be easily welded, bent, and applied even in hard to reach places.

In addition to these advantages, air ducts have some disadvantages:

- they are unstable to mechanical intense action;

- with poor installation, such ventilation devices can make noise, subtle sounds.

Installation Rules

Mounting ventilation equipment is a rather time-consuming process. It is important to consider not only the tasks of air exchange, but also the maintenance of the necessary humidity inside the premises, control of the purity of the incoming air.

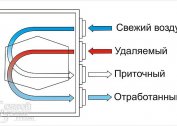

Important. In exhaust ventilation systems used, a single exhaust hood is used to exhaust smoky or contaminated air. And in the case of the use of supply and exhaust systems, two hoods are used (one for the intake of clean air, the other for the output of contaminated).

There are uniform rules for installing ducts:

There are uniform rules for installing ducts:

- it is necessary to ground the mounted device, so that during its operation to avoid the accumulation of static electricity;

- at the design and installation stage of such systems, it is necessary to take into account the property of aerodynamics, since the air in the ventilation pipes from the stainless steel moves in a spiral;

- flexible and semi-flexible products must be mounted under full tension;

- on the basement and basement floors, in areas of contact with the ground, and also in structures that pass through ceiling or floor ceilings, use the installation of rigid devices;

- if during installation the air duct was damaged, it must be replaced;

- if ventilation is required to be mounted at an angle, then given that with sharp turns of the pipes the aerodynamic properties of them decrease, it is necessary to make the radius of such a turn not less than two diameters of the mounted duct.

The rules for proper installation often depend on the brand of stainless steel used, the method of installation.

Mounting Methods

Installation of ventilation systems is carried out using:

- flanges, with rivets, bolts;

- socket, with the joining of pipe ends, tightly fixed on the outside;

- tires providing good tightness due to the tightening special locking element using rubber or foam gaskets;

- electric welding, providing the best impermeability of joints with a special heat gun.

Tip. To prevent deformation of the product, its elements must be fixed with long brackets, and the ventilation pipes must be fixed with special clamps that are tightened with an open-end wrench.

To reduce the noise level during operation of ventilation devices, they are equipped with silencers.

Conclusion

As you can see, the use of stainless steel ducts is quite widespread in many areas of our lives.None of the enterprises of industry, consumer services, catering or trade can do without the installation of ventilation systems, ducts for supplying clean air to the premises and removing used, contaminated or smoky air.

They are equipped with:

- offices, clubs;

- restaurants, cafes, bars;

- apartments, cottages;

- industrial premises.

In this case, it is desirable to take into account a number of aspects:

- circular ducts are usually straight-seam;

- they use round stainless steel devices more often to remove air from boiler rooms, to clean from smoke, chemical fumes, gas;

- rectangular type products are often used as gas ducts, as well as for smoke removal in chemical plants.