Aluminum radiators are an excellent solution for heating rooms connected to autonomous heating systems. The battery has a long service life, excellent heat dissipation, affordability. Lightweight and durable alloy provides resistance to corrosion and high pressure. To increase resistance to external negative factors, the surface is coated with protective polymers.

Application area

Aluminum batteries are mainly used in private housing construction with autonomous heating, as in this case it is possible to provide the necessary water quality, adjust pressure indicators and control the flow of coolant. Installation locations may include:

- Living spaces;

- outbuildings;

- industrial enterprises;

- garages, hangars, warehouses.

Aluminum radiators are mounted in buildings with their own, decentralized heating system.

Specifications

The main technical characteristics of aluminum batteries include:

- the weight of one section does not exceed 1.5 kg;

- indicators of working pressure are from 6 to 24 atmospheres;

- water filling of each section up to 0.46 liters;

- heat transfer up to 205 W;

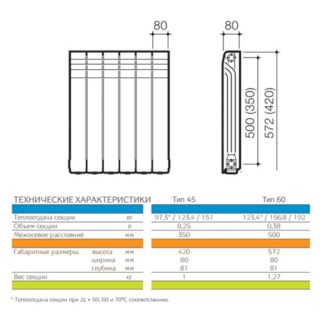

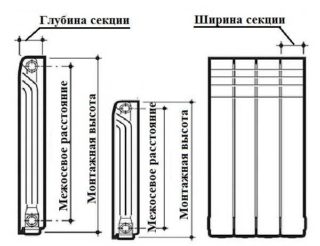

- widespread section width - 80 mm;

- the maximum temperature of the coolant is 110 ° C (the maximum limit of some Rifar specimens is 135 ° C);

- service life up to 20 years.

The number of sections in factory-assembled structures varies from 4 to 12. All segments are attached to each other by a nipple connection. Serial production produces models with center distance:

- 200 mm;

- 300 mm;

- 350 mm;

- 500 mm (the most popular representative);

- 600 mm;

- 800 mm.

Structures with a center distance of 900 to 2,000 mm are included in the Global product range.

Advantages and disadvantages

The aluminum heating radiator has several advantages:

- a light weight;

- attractive external characteristics that harmoniously fit into any interior, design solution;

- optimal heat transfer, which allows you to reduce the size of the battery and save space;

- maintainability, material in case of cracks easily solders;

- ease of installation, care;

- budgeting.

There are also some disadvantages:

- restrictions on the quality of the coolant;

- low resistance to aggressive environments;

- lack of protection against water hammer;

- propensity for gas formation.

Aluminum batteries are not used for buildings with a centralized heating system, multi-unit, multi-storey buildings. When installing such models, special devices must be provided for regular air bleeding.

Varieties of aluminum radiators

Cast

Models of this type are produced by casting using an aluminum-silicon alloy. The liquid composition under high pressure is poured into a special form in which it cools, after which it undergoes the necessary processing and preparatory pre-sale procedures:

- removal of excess parts, sagging;

- soldering the neck;

- leak test;

- applying a corrosion-resistant coating on the outside and inside;

- drying-painting-drying;

- additional leak test;

- assembly to a certain size;

- packaging.

The presence of at least 12% silicon in the melt helps to increase the strength of the material. The section consists of the following fundamental elements:

- fins plates needed to increase the heat transfer area;

- a passage channel with a vertical arrangement with the smallest diameter in comparison with a similar horizontal part;

- outer coating;

- feedthrough channels with threads on top and bottom.

The connection of the sections occurs through steel nipples.

Extrusion

The second method for the production of aluminum-silicon alloy batteries is called extrusion and consists of the following steps:

- using stamping, sheet blanks are transformed into individual parts of the specimen;

- the edges of the structure are processed and ground;

- the resulting elements are placed in a mold and are connected to each other by high pressure;

- seams are additionally soldered;

- leak test is carried out;

- painting;

- assembly of the model from the required number of sections;

- packaging.

Products obtained by extrusion are slightly inferior in technical and operational characteristics to cast radiators.

Anodized

Anodized type radiators are produced from alloy, where the main 98% is aluminum, which has passed a high level of purification. In this case, all internal and external structural parts undergo anodic / electrochemical oxidation, covering the surface with a special film. The process improves the corrosion resistance of the battery and increases its resistance to destructive chemical influences.

Steps for creating an anodized section:

- washing with an alkaline solution to remove various contaminants from the surface;

- etching / chemical milling;

- neutralization - removal of heavy metals;

- anodizing by immersing the product in a container with electrolyte;

- adsorption staining (if necessary);

- clogging of pores.

Anodized sections are connected using dry outer couplings, so the inside of the joints remains smooth and does not taper. These factors make it possible to eliminate stagnant processes and ensure the movement of a coolant with a small hydraulic resistance.

Radiators created using this technology are characterized by high heat transfer rates and the ability to withstand the maximum pressure level of up to 70 atmospheres.

If we consider all types of aluminum batteries, only anodized specimens have the necessary qualities for use in a centralized heating system. Such designs have one drawback - high cost.

Coolant features

Heating aluminum batteries require that the coolant be of high quality. Most often, water is poured into the system, but it can lead to some negative consequences over time:

- the formation of scale, sludge;

- occurrence of corrosion.

All this leads to the need for regular flushing, which is not always possible during the heating season.

If possible, experts recommend using non-freezing and non-chemically reacting liquids as a heat carrier.

Antifreeze

This composition includes special additives, additives that minimize the appearance of mineral deposits and the development of corrosion. Despite the many advantages, antifreeze has the following disadvantages:

- reduced thermal capacity;

- a circulation pump is required to start the system;

- increased fluid expansion during heating;

- high level of fluidity, which requires special attention to the integrity of the joints and threaded joints.

When using ethylene glycol compounds, it is not possible to connect hot water supply.

DIY coolant

Antifreeze can be prepared independently, for this you will need 40% ethyl alcohol and distilled water. The resulting consistency is sometimes much better than the factory, this is due to lower viscosity. The advantages of a self-made coolant include:

- maintaining the integrity of rubber seals;

- resistance to scaling;

- lack of alcohol fumes;

- easy removal of solid sediment by normal washing with running water.

The boiling point of the liquid is similar to water, which allows heating to 90 ° to avoid excessive steam formation. Ethanol has the property of reducing the expansion of water that occurs during heating, which reduces the risk of pipe / radiator rupture during defrosting.

To obtain an optimal 33% solution, 2.9 liters are required. distilled water and 1 liter. ethyl alcohol. Such a coolant does not freeze to -23 ° C.

Factory and self-made antifreezes are strictly prohibited in the following cases:

- open heating system;

- temperature below -20 ° C;

- in the area of connections, a linen tow was used, planted on a paint that is easily corroded by alcohol, which causes depressurization;

- galvanized elements are present in the system: pipes, fittings, pipes.

Since aluminum radiators are demanding on the coolant, it is important to take this issue as seriously as possible.

Rules for choosing a battery of aluminum

When purchasing a radiator, it is important to consider the following factors:

- pressure - for an aluminum battery, the limit is 4 atm, which is the best indicator for low-rise construction;

- external characteristics;

- manufacturer;

- cost - it is not worth saving critically when choosing parts of the heating system;

- number of sections - with their number, the volume of heat transfer increases;

- power - should be more than 20 times that of the boiler.

Before buying, it is recommended to familiarize yourself with the information available, consult with specialists, read reviews. The purchase of an aluminum radiator is a responsible procedure, which cannot be treated after the sleeves, since the operability of the entire heating system depends on this.