The stove in a wooden house can be built independently or put the finished unit. It can be metal or made of brick, equipped with a fireplace or hob. Proper installation of the furnace design implies compliance with fire safety requirements.

Variety of stoves

Home stoves are made of brick and metal. Due to the design features, each option has certain advantages and limitations to implementation.

Brick

Due to the long cooling time, such a furnace maintains heat indoors for a long time. It is able to serve a large-sized housing, resistant to fire. Thinking over the design, it is possible to provide for the possibility of cooking food and even a stove bench. When planning the installation of such a furnace in a wooden house, you need to remember that the design requires the arrangement of a solid deep foundation. If there is no experience, it is better to entrust the construction to a specialist, but you can do it yourself.

Metal

Heating constructions are iron and cast iron. The walls have a two-layer structure; the air layer between the sheets of metal protects the home from heat shock. Such stoves are attractive due to the possibility of acquiring a finished system with a chimney and a temperature control unit.

Devices are quick heating and heat transfer. Because of this, you have to heat often, if it is not a unit with the option of slow combustion. You can choose a fireplace stove or a structure equipped with cooking appliances (oven, hob). The main disadvantage of these products is the increased risk of fire. Because of it, additional safety requirements are introduced during installation.

When choosing, you need to build on what type of fuel you plan to use. For a wood stove, the chamber is made of refractory bricks, for a coal stove, it is made of red with chamotte lining. If peat briquettes are selected, a pair of metal grates must be mounted on the furnace chamber.

Chimney selection and installation

Ceramic chimneys are distinguished by the best performance. They are durable, give good traction, condensed moisture does not settle on the walls. Also reduced fire hazard sleeves made of brick.

Ceramic chimneys are distinguished by the best performance. They are durable, give good traction, condensed moisture does not settle on the walls. Also reduced fire hazard sleeves made of brick.

If a galvanized pipe is chosen as the basis, it is necessary to take care of the isolation of joints with wood and roof with non-combustible materials.

In chimneys from a “sandwich” after 10 years of use, separation of the layers from each other may begin. But they do not require additional insulation.

Regardless of the material chosen, you need to equip the chimney with a hatch to clean it from soot accumulations.

The location of the stove in the house

The place in which the furnace will be installed in the house depends on the features of its functioning. The location of the chimney and the approach to the stove for its maintenance are calculated (cleaning the chamber, removing ash and soot).

The distance from the hot surface to the wall should be at least 1.1 m. This is necessary to minimize the likelihood of a fire.

An iron stove can be installed in the partition between rooms to serve the rooms nearby.

The need for foundation and types

If the stove weighs less than 80 kg, it should be put on a strong base of non-combustible material.A lightweight cast-iron unit can be placed on a concrete base. With a mass of more than 300 kg, especially if it is planned to finish with facing material, it is necessary to organize a serious foundation.

On poles and stilts

Using screws made of steel, it is possible to organize a foundation that can withstand a massive cast iron stove lined with bricks. After screwing into the soil, the piles are bonded from above, and then concrete is poured.

The disadvantage of this option is a rather high cost. Screws are rotting, they serve about half a century.

An inexpensive option, easy to implement and suitable for most furnaces (except for the heaviest options) is columnar. Recesses are drilled in the ground, into which pillars of wood or concrete are clogged.

Concrete

Concrete foundations have good ability to withstand heavy structures and ease of installation. The only drawback is the duration of the work. Sanitary regulations forbidden to organize a common foundation for the stove and the building itself. In violation of this rule, the base of the building can be squeezed out of the soil in the winter, sometimes to a considerable height. This provokes a violation of the integrity of the lining and the heating unit itself.

It is often practiced to organize the base of the tape type, when along the perimeter of the future location of the stove they dig a trench with a depth below the freezing level. A mesh for reinforcement is placed in it and concrete mortar is poured. Another option is to create a monolithic slab with a thickness of about 0.2 m. The arrangement begins, scattering sand and gravel mixture over the required area, pouring a little water on top and ramming it. Spread a layer of waterproofing on top and put tags for the screed. When it is flooded, they cover it with a film. For 14 consecutive days, the surface is watered to prevent cracking. It is possible to mount the furnace on a concrete base one month after the end of work.

Fire safety regulations during installation

Before installing the stove in your home, you need to protect the walls and floor from possible capture by fire. Particular care is needed when mounting metal assemblies. For protection, mastics and impregnating compounds with a flame retardant are used, as well as sheets of non-combustible insulating materials installed on the walls, ceiling and floor in places of contact with the stove. Chemical compositions are used to process load-bearing elements, beams and all areas adjacent to the unit. Impregnations are good because they do not stain materials, but mastics have better protective properties.

If the treatment is carried out by the homeowners themselves, they need to first obtain a certificate from the Ministry of Emergencies, confirming that the installation of the stove meets the fire safety requirements.

The ceiling is protected from ignition by plasterboard treated with putty for painting. Basalt cardboard coating is installed on the walls, and steel shielding on top. Other options - coating with a thick layer of plaster (more than 3 cm) and brick lining.

Do-it-yourself stove installation in a wooden house

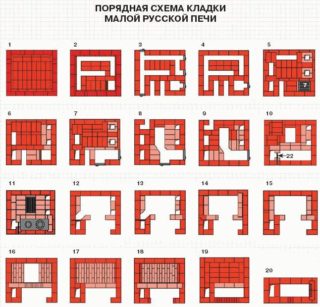

When the foundation is ready to place the furnace on it, you can begin installation work. Finished heating equipment is installed according to the instructions of the manufacturer. If you decide to do the construction yourself, before you start all the work, you need to think through its design and prepare a layout indicating all significant dimensions (including the furnace and the blower). A step-by-step guide to installing a brick Russian stove with your own hands looks like this:

When the foundation is ready to place the furnace on it, you can begin installation work. Finished heating equipment is installed according to the instructions of the manufacturer. If you decide to do the construction yourself, before you start all the work, you need to think through its design and prepare a layout indicating all significant dimensions (including the furnace and the blower). A step-by-step guide to installing a brick Russian stove with your own hands looks like this:

- A two- or three-layer waterproofing lining is prepared from roofing felt or roofing material. The distance to the gas ducts should be more than 0.45 m.

- The location of the beams is calculated so as to ensure the remoteness of the passing chimney pipe from the matrix elements between the rafters.

- The bricks are laid obliquely, starting from a pair of racks opposite each other. This method provides a uniform distribution of the clay mixture and will prevent the weakening of the joints caused by its sliding. When laying, the configuration is constantly checked with the prepared layout. The plumb line will help to evaluate the evenness. The combustion chamber is laid out from the grate.

The completed design is left alone for at least a day. Then it can be plastered or tiled.

Installation of the stove in a wooden dwelling requires attention to the rules of fire safety. Of great importance are the selection of construction materials and the installation of protective screens on the walls.