Amid the ever-increasing cost of utilities, an increasing number of citizens are paying attention to alternative energy. Disruptions in the supply of services, which happen more and more often due to deterioration of communication lines, contribute to this. Hydrogen heating is one of the analogues of traditional gas, electricity and solid fuel. This is one of the most promising areas, allowing you to not depend on utilities. The market is gradually saturated with factory-made devices, but if you have the skills to handle household tools, you can design and assemble a hydrogen generator for heating yourself.

The principle of operation of the hydrogen boiler

The hydrogen heating boiler works on the principle of heating the liquid in the heat exchanger with the fire burning fuel in the chamber. The source of energy is pure H2. Gas has a high heat transfer, which is 3 times higher than that of propane. The only difficulty in obtaining it is the high activity of the element, due to which it binds to other substances. Separation is required, which requires electricity.

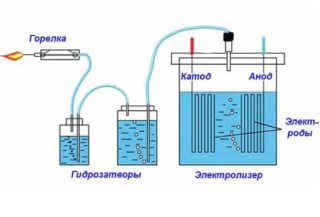

The general scheme of the hydrogen heating system is as follows:

- Gas production. Distilled water is used as raw material. It is poured into the tank, where the electrodes are placed. Under the influence of current, water molecules decompose into oxygen and hydrogen.

Isolation of H2. The mixture is passed through a chemical separator that releases hydrogen and sends it to the burner, where it is ignited and burned. A valve in the pipeline prevents gas from flowing in the opposite direction. The combustion level is regulated by opening or blocking special channels through which hydrogen is supplied.

Isolation of H2. The mixture is passed through a chemical separator that releases hydrogen and sends it to the burner, where it is ignited and burned. A valve in the pipeline prevents gas from flowing in the opposite direction. The combustion level is regulated by opening or blocking special channels through which hydrogen is supplied.- A catalyst is supplied to the burner, which reduces the temperature of the flame from 2000 degrees to a safe 600 degrees, which allows the use of low-cost metals for the manufacture of the chamber. Formed during the combustion of steam through a coil enters the tank with water, where it condenses and replenishes the consumed liquid.

- Oxygen released during electrolysis is discharged into a separate chamber, where it is mixed with air and enters the room through a valve.

Provided that there is an electric generator in case of light failure, the system can be considered autonomous, since the water reserves in nature are unlimited.

Advantages and disadvantages

Like any heating equipment, a hydrogen boiler has its pros and cons.

Advantages of devices:

- lack of toxic emissions during fuel combustion;

- almost free fuel - clean water has a symbolic value;

- high efficiency, reaching 0.96;

- saving of minerals through the use of renewable energy sources;

- low cost - hydrogen heating at home consumes a small amount of electricity, which can be obtained from solar panels, a battery or a generator, in the absence of an industrial network.

Has home heating with hydrogen and its drawbacks:

- high cost of equipment;

- the need for regular maintenance and replacement of consumables (electrodes, communications);

- dependence on continuous replenishment of the catalyst;

- deficiency of hydrogen cylinders for direct connection devices;

- a small selection of boilers in the distribution network;

- the difficulty in finding qualified specialists for installation and maintenance of equipment.

Technologies in this industry are developing rapidly. Hydrogen heating is becoming more advanced, more economical and safer. It is possible to heat the house with pure hydrogen, since it is much more economical than propane.

Hydrogen plant equipment set

A hydrogen generator for heating a private house is simple and thoughtful device.

The equipment consists of such parts and mechanisms:

- Boiler. It is made of heat resisting steel. Serves to place parts and protect them from external influences.

- Electrolyzer. It is a sealed plastic reservoir, with electrodes. Serves to decompose water into hydrogen and oxygen molecules.

- Burner valve. Arranged in such a way that only H2 in its pure form passes through it. Evolved steam and oxygen enter another, more rigid valve.

- Burner. The product is in the combustion chamber, it is ignited automatically or in manual mode. Serves to give the gas stream an optimal configuration.

- Pipeline. The piping from the pipes supplying the coolant to the radiators and the storage tank. Today, reinforced plastic pipes with a diameter of 25 mm and 32 mm are used.

Modern equipment is equipped with a control unit to configure its operation parameters.

Criteria for choosing a hydrogen boiler

When choosing a device for heating a house with hydrogen, you should be guided by the following criteria:

- power;

- dimensions;

- weight;

- volume of water consumed;

- number of circuits;

- consumed electricity;

- fuel (from cylinders or water by electrolysis).

It is recommended to purchase products equipped with safety blocks that minimize the risk of breakage and explosion.

Operation tips

Given that hydrogen is extremely explosive, handling a boiler requires increased safety measures.

When operating heating equipment, the following recommendations must be observed:

- Do not use open fire near the boiler;

- install the boiler away from heating appliances;

- set the power correctly to prevent overheating of the device;

- promptly clean the water tank and change the electrodes.

It is advisable to equip the equipment with flame sensors, water temperature and a standard cooling device. This will make the boiler completely safe.

DIY hydrogen boiler design

The beginning of work is drawing up a drawing, on the basis of which the calculation of materials and the need for tools is carried out.

DIY hydrogen boiler is made in the following sequence:

- Creating a housing with stops for installing heater parts.

- The manufacture of an electrolyzer. Installation and connection to the wires of the electrodes.

- Mounting the burner. It is better to use a factory-made part.

- Fastening the catalyst tank.

- Laying communications, installing valves for separating a mixture of gases.

It is better to carry out a test run of the boiler before it is connected to the piping, in order to leave the opportunity to eliminate the shortcomings.

Manufacturers

Today, the products of such manufacturers are most popular among consumers:

- H2ydroGEM;

- MegaTank100;

- STAR-2000;

- H2-2;

- Free Energy

The cost of production varies between 20-100 thousand rubles, depending on capacity and other characteristics. The goods should be purchased only at specialized outlets after checking the quality certificate.