The appearance of radiators or batteries does not always satisfy aesthetic requirements. Simple surface painting does not solve the global design problem. To give harmony to the interior, grilles for radiators and radiators are installed: decorative, wooden, plastic. But their function is not limited to improving the appearance.

Purpose of radiator grilles

The decorative panel on the radiator (battery) for heating is designed to hide its surface. Their installation should not affect the operational characteristics of system elements. At the same time, decorative grilles on heating radiators perform a protective function. The temperature of their surface is much lower than that of heating appliances.

To perform these tasks, the design must ensure normal air circulation around the heater. Also a prerequisite is a simple dismantling for the operational repair or maintenance work. Therefore, before making decorative grilles on heating radiators with your own hands, you need to familiarize yourself with the features of factory designs:

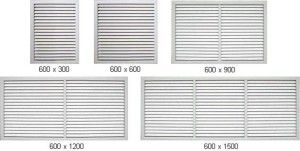

- The dimensions of the panel should exceed the size of the battery by 10-15 mm, depending on the shape of the latter;

- After installation, the distance between the surface of the radiator and the protective screen is at least 20-25 mm. This is necessary to create convection flows;

- Metal or wooden grilles for heating radiators have a mesh surface for frontal and lateral air flow to the battery.

One of the key points is the minimal contact area of the hinged structure with the heating element. This is necessary to minimize heat loss and mild heating of the surface of the grating.

Regardless of the model you choose, whether it is metal grilles on heating radiators, wooden or plastic - during the heating process they should not emit harmful elements or unpleasant odors.

Types of lattice designs

What options affect the panel selection? The dimensions of the battery and its position in the wall opening are decisive. Most often, it is installed in a special niche, the upper part of which is a windowsill. If it is necessary to close this whole area, the dimensions of the grill for heating radiators are selected based on the dimensions of the mounting recess in the wall.

In this case, do-it-yourself front grille is installed. This is one of the simplest designs, as it can be attached to both the battery and the wall.

The ability to select the type of mounting units greatly facilitates the independent manufacture of panels.

In addition, they make such lattices on radiators with their own hands:

- Hinged, without side panels. They are installed directly on the upper plane of the battery;

- Mounted, with top cover. They can close the design of the heating element not only from the front, but also from above. Actual if the battery protrudes slightly due to the wall plane;

- Box. The installation of these decorative grilles on radiators completely hides the design.

In addition to the aesthetic component, the complete closure of radiators is recommended in the children's room. Mandatory installation of metal grilles on heating radiators in public buildings - children's hospitals, schools, gyms.

The upper part of the decorative lattice should protrude beyond the edge of the window sill at least 2/3 of its depth.This is necessary for normal air convection.

Choose the material for the manufacture of the lattice

The manufacture of decorative grilles for heating radiators with their own hands should begin with the choice of material. It must withstand high temperatures without emitting harmful fumes. An important point is the preservation of form and initial appearance.

Can plastic grilles be used for heating radiators or are steel and wood models the only alternative? To solve this issue, you should find out the properties of each type of manufacturing material and their operational features.

Steel grilles for radiators

This is the most common type of panels, as manufacturing is possible in various ways. Most often they make a steel grill of a heating radiator with their own hands of a frame type. To do this, you can use the "black" metal or galvanized. Stainless steel structures are mainly factory-made.

In addition to the size of the grilles, heating radiators need to pay attention to the method of painting the body. The best option is powder technology (baking). Such a protective and decorative layer does not change its shade during high-temperature operation of the system. In addition, the selected panel must have the following properties:

- Ventilation holes on the front and side;

- The optimum thickness of the steel is 0.8-1 mm;

- After installation, it will provide free access to all elements of the radiator harness - the Mayevsky crane, thermostat, shutoff valves.

To make such a lattice on a heating battery with your own hands, you will need a welding machine. It is best to use an inverter, as it can work with thin-walled metal.

For self-painting, you need to use only special heat-resistant enamel or paint.

Wooden grilles for radiators

The most aesthetic appearance of the room is given by wooden lattices for radiators. For their manufacture, you need to take special varieties of trees that, under the influence of temperature, do not emit tar.

Making a panel of MDF or chipboard is not recommended. In the production process of these materials, adhesive compositions are used. Even if they are neutral to high thermal influences, the surface is highly likely to deform. This is due to the natural thermal expansion and compression of the adhesive layer. Subsequently, this can lead to delamination of the panel.

The best option is to use deciduous trees. It is first necessary to dry the workpiece to reduce moisture. This indicator should not exceed 12-15%. Then you should perform the following actions:

- Treatment with antibacterial composition. Protection against mold and microorganisms in wood fibers;

- Production of structural elements and assembly;

- Paint coating.

All these steps for assembling decorative panels on heating radiators must be performed in a room with a temperature of 18 to 25 ° C and normal humidity. Also, flow ventilation must be present.

It is not recommended to purchase wooden grilles for heating radiators made by handicrafts. Failure to comply with the technology can cause premature loss of appearance of the panel.

Plastic grilles for radiators

For the manufacture of plastic grilles for heating radiators, PVC-based compounds are most often used. With the right technology for manufacturing plastic, the product can withstand temperatures up to 95 ° C without loss of appearance.

It is impossible to make such models of decorative grilles for heating batteries on their own. An alternative is the acquisition of factory panels.The main selection options are as follows:

- Plastic should be colored in bulk. The presence of a laminating film on the surface is unacceptable;

- Plastic should not be flammable. Under the influence of an open flame, it melts, not supporting the combustion process. Similar compositions are used for the manufacture of PVC profiles for window structures;

- Unlike metal grilles on radiators, plastic models do not have good mechanical strength. This should be taken into account when choosing panels for a nursery or a gym.

The advantage of plastic panels is their low cost and a variety of shapes. But at the same time, they lose their original appearance faster than metal or wooden grilles on heating radiators.

Harmful substances from PVC are released only during smoldering or burning (temperature is about 220 ° C). If during operation of the plastic grill an unpleasant odor appears, it is possible that the film is burned out or the wrong manufacturing material was initially selected.

DIY radiator grilles

The optimal material for making a decorative panel at home is metal. To do this, you can use galvanized steel sheet and corners 15 * 15 mm. But first you need to choose the dimensions of the grill for heating radiators.

The dimensions of the structure depend on the selected type of grating, which was mentioned above. Therefore, you must first measure the battery and add 10-15 mm in height and width to the data obtained.

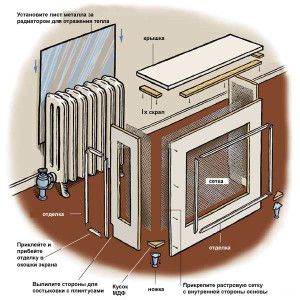

Regardless of the material chosen, the general manufacturing scheme should consist of the following steps:

- Battery metering and design drawing;

- Making corners and forming a frame;

- Installation of the grill in the resulting structure;

- Installation of support nodes that will be in contact with the surface of the radiator.

Then apply a protective layer. On top of it, you can add a decorative pattern of heat-resistant paint. The resulting self-made heating radiator grill will be checked for the effect of a temperature equal to the maximum degree of heating of the coolant in the system.

When drawing up the circuit, it is important to consider the presence of technological holes. They are necessary for free access to the battery elements - stop valves, thermostat and Mayevsky tap.

An example of installing a decorative box on a battery: