Insulation of the floor in a frame house on screw piles should be carried out with mandatory consideration of design features. In this case, the floor should be light so as not to burden the base of the house, and at the same time strong. Thermal insulation of this part of the structure is extremely important, therefore it is recommended to use high-quality wood for repair work. This is due to the ease, warmth and purity of the material. To increase thermal insulation, floor insulation is additionally carried out using various building materials.

Floor insulation options

There are two ways to insulate the floor in a frame house on stilts: external insulation along the entire perimeter of the house only from the floor side and complete.

The essence of the first is to build a basement frame from the soil to the beginning of the walls of the house, along its entire perimeter. Based on the financial capabilities and climate conditions in the region of residence from the outside, insulation and lining are carried out. This method is preferred for buildings with a low location from the soil surface.

If this method cannot be used due to the fact that the floor is too high from the soil level, warming is carried out only from the outside.

Full (complex) floor insulation is considered the most optimal. For its implementation, the surface is insulated inside and out. The process is divided into the following steps:

- waterproofing grillages and metal piles;

- construction of the base of the basement;

- insulation of the inside of the cap;

- installation of panels for decoration on the base;

- expanded clay and / or soil insulation inside the basement;

- installation of floor insulation from the basement;

- insulation and waterproofing of the strip foundation.

The listed set of measures will prevent moisture from entering building materials and prevent the loss of heat from the room.

Examples of materials used

When choosing materials for insulation, you need to carefully familiarize yourself with their characteristics, especially indicators of wind protection, waterproofing and vapor barrier.

Mineral wool insulation

Minvata has a large number of advantages, the main ones are excellent thermal insulation characteristics, incombustibility. The material is not subject to biological influences. However, if even a small amount of moisture gets on the substance, it will sag and partially lose its properties. Compared with other types of building material, mineral wool insulation has a high cost.

They produce raw materials in the form of plates and rolls. It is better to insulate the floor on piles with plates, since they are characterized by greater rigidity. Depending on the feedstock, there are slag, glass and stone wool.

When working with mineral wool, personal protective equipment must be used: a mask, gloves and protective clothing.

Styrofoam

Polyfoam is the most common insulation. This is due to excellent indicators of thermal protection and acceptable cost. When buying, it is important to consider that when exposed to high humidity in combination with low temperatures, the foam can crumble into small balls. Structural changes will inevitably lead to violations of the thermal protection of the building.

If the owners of the house decided to use polystyrene for floor insulation, it is worth taking extra care to protect it from moisture.

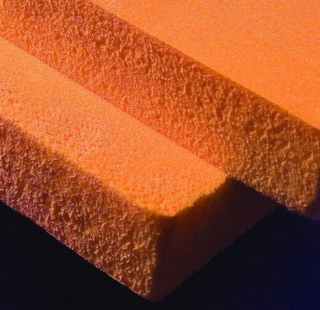

Extruded Styrofoam

Insulation of the floor in a wooden house on screw piles is often carried out using extruded polystyrene foam - "Penoplex". Visually, it resembles polystyrene, but has the best characteristics.

Raw materials have lower water absorption combined with high strength. Thanks to these features, you can not worry about the destruction of the structure of the material with prolonged exposure to low temperatures. The composition of the extruded polystyrene foam is enriched with special additives that allow it to belong to the group of non-combustible materials.

Thermal protection characteristics of the listed heaters are almost identical.

There is another material - expanded clay. In terms of thermal insulation, it is inferior to the other mineral wool, polystyrene foam and polystyrene foam, but at the same time it has a low price, is easy to install and non-combustible.

Foundation insulation options

There are several ways to warm the foundation of wooden houses built on screw piles.

Waterproofing structures

At the initial stage of the work, the grillage and foundation piles must be carefully treated with bituminous mastic to exclude the negative impact of dampness on the building materials from the soil. All elements made of wood are treated with an antiseptic that creates a protective film against insects and mold. If mineral wool will be additionally used, a vapor barrier film is provided in the thermal insulation layer to protect the raw material from moisture absorption.

The construction of the basement frame of the house

To install a heater outside the screw type of the foundation, you must first build a frame of vertical and horizontal guides. The interval between the bars should be equal to the width of the insulation boards, otherwise many cracks and cold bridges will form in the house. For additional protection, the entire frame is treated with coating waterproofing, and rolled waterproofing is laid on top.

Fixing insulation on the base

When insulating the base with extruded polystyrene foam or polystyrene, it is important to process the seams formed between the plates of the material with a mounting foam. If the insulation will be carried out with mineral wool, the plates should be pressed tightly against the bars, if there are any ventilation left, the heat from the room will “go away”.

It is important to protect any used insulation material from the outside of the house from attacks by rodents and possible mechanical damage.

Installation of decorative panels

With self-insulation of the base with foam, the decorative cladding is made of metal or vinyl siding, basement panels. To do this, a starting profile is installed on the base around the perimeter, as when warming the facade of a mineral wool insulation, to which the finishing lining is attached outside on the street. Finishing the basement of the house will protect the insulation layer from mechanical damage and precipitation.

Insulation of structures should always be carried out from the street. Such an approach to work will protect the insulation layer from freezing and increase the operational life.

Ground floor insulation

The soil under the house can be covered with a thick layer of expanded clay. This will protect the house from the cold, which will come from the ground in the cold seasons, as well as reduce floor blowing. It is additionally recommended to warm the floor of the first floor with mineral wool. On the walls of the basement from the opposite sides make holes for ventilation of the basement. With the advent of winter, all ventilation openings are closed, otherwise the invasion of rodents cannot be avoided.