Isolon is a light-weight plastic insulation made by foaming polyethylene with small cells and closed pores. The structure of the final product allows its use for heat, hydro and noise insulation of various designs. Externally, the material is similar to foam, may have aluminum foil. It is delivered in rolls, blocks, sheets.

Isolon specifics

Isolon based on fine-mesh polyethylene foam is characterized by high thermal insulation performance and low weight. Some modifications are made with single or double-sided lamination with aluminum foil. The coating thickness is 14 microns and provides water resistance, as well as reflective properties.

The material also has a reinforced frame in the form of a propylene mesh. The basis of Isolon is self-adhesive or glueless. On sale there are combined varieties with foil and adhesive base. To prevent sheets from sticking together during transportation, a protective film is applied to the adhesive surface.

Technical indicators

Technical specifications depend on the type of material that can be stitched (PES) and unstitched (NPE). Consider the indicators appropriate in the table.

| Characteristic | NPE | PES |

| Styling temperature | -80 to +80 degrees | -60 to +75 degrees |

| Thermal conductivity, W / m * K | 66 | 0,040 |

| Water absorption,% | 0,02 | 1 |

| Vapor permeability, mg / (m * h * Pa) | 0,001 | 0,001 |

| Sound insulation,% | 13 | 68 |

| Density, kg / m3 | 19-35 | 25-200 |

The life of stitched and non-stitched material is 80 years.

Material dimensions

Dimensions depend on the type:

- Foamed without lamination. It happens from 0.5 to 10 mm in thickness, it is delivered in rolls of 1.05x200 / 50 m.

- With lavsan lamination. Available in 2,3,4,5,8 and 10 mm thick, packed in rolls of 1 / 1,2x25 m.

- Foil. The thickness of the material is 2,3,4,5,8 and 10 mm, deliveries are made in rolls of 1 / 1.2x25 m.

- With one metallized and second adhesive side. The thickness is 2,3,4,5,8,10 mm, available in rolls of 1 / 1.2x25 mm.

- On a self-adhesive basis. It has a thickness of 2,3,4,5,8,10 mm. It can be purchased in rolls of 1 / 1.2x25 m.

- Hard sheet. It differs by a thickness of 20-50 mm, supplied in sheets of 1x2 m.

For construction purposes, a material with a thickness of 5 and 8 mm is suitable.

Main varieties

Thermal insulation Izolon depending on the structure is divided into several types.

Isolon PES

Crosslinked material is made by connecting carbon and hydrogen chains into a molecular 3D network. It is problematic to break ties, therefore the main characteristic of Izolon PES is increased strength. The crosslinked type insulation has a different marking:

- 500 and 500 L. It is made on the basis of polyethylene, physically connected in a vertical furnace. The structure of the sample is ligation in the transverse direction;

- 500 HP Material with a similar structure made in horizontal furnaces;

- 500-300. The manufacturing process involves foaming the polymer and adding chemical elements to it in horizontal furnaces.

Air bubbles remain in the composition of the PES; therefore, it is light and characterized by a low density.

Isolon NPE

It is an extruded polyethylene foam with a non-crosslinked structure. The polymers acquire the state of foam after the introduction of a blowing agent, which provides closed pores with an even structure and a density index of 26 kg / m3. The thermal conductivity of the NPE is 0.040 W / m * K - 1 cm of material can replace 1.4 cm of Penoplex insulation, 16 cm of brickwork and 5 cm of beams.

Features of the uncrosslinked Isolon include:

- high-quality steam and moisture protection - closed cells exclude water absorption around the entire perimeter of the sheet;

- soundproofing;

- environmental safety - foaming gas is not used for foaming;

- compatibility with all types of building materials;

- durability and non-rotting due to the polymers in the composition.

NPE is easy to cut and lay in a special crate.

Foiled

A foil film of 14 microns thick is applied to the material from one or two sides. The coating contributes to the reflection of 97% of the heat and therefore the thermal insulation works like a thermos. You can insulate with foil isolone any room because of its properties:

- vapor permeability of 0.031 - 0.04 mg / m * h * Pa - walls and finishes do not damp, do not become moldy;

- minimum moisture absorption - moisture does not penetrate into the material and condensation does not form;

- soundproof characteristics - does not absorb sounds from 32 dB;

- light weight - provides quick cutting and lack of reinforcement during installation.

Foiled Isolon may be used indoors.

Areas of operation

The universality of the characteristics determines the use of the material in many areas:

- substrate - after warming the rough floor with Izolon, you can lay a carpet or laminate in a wooden house;

- protection of communication systems - climate and refrigeration units, gas, water, and ventilation lines;

- thermal insulation of any surfaces - underground, walls, roofs, ceilings or basement;

- warming of farm buildings (bath, sauna) and utility rooms.

The insulator is also used in commercial construction.

Features of warming the loggia

To warm the balcony or loggia, you will need a roll Izolon, as well as a drill, screwdriver, parallel bars 2x4 cm and 5x4 cm, a stationery knife, a stapler for furniture. Using the material, it is easy to create a kind of cocoon that retains heat:

- Fix the slats vertically on the walls in 90 cm increments.

- Form a layer-by-layer thermal insulation - put foil Isolon 5 mm thick at the bottom, then polystyrene foam, then again foil isolon 3 mm thick.

- Fix the thermal insulation with a stapler. One edge is fixed with staples, the remainder is pulled to the rail and nailed with staples.

- Seal the joints with metal tape or masking tape.

- To process wide gaps with polyurethane foam in order to eliminate “cold bridges”.

Warming of the loggia Izolon is a foil layer inside.

Creating wall insulation

Foil insulation is best suited for walls - the shiny surface of Izolon will direct heat energy back into the room. With a sticker on a polyethylene base, good sound, moisture and vapor barrier can be achieved. The work is carried out as follows:

- Installation of wooden slats 2x4 cm with a gap of up to 1 m.

- Laying mineral wool in a frame at odds.

- Fastening foil isolone to the bars using a stapler - a shiny layer is directed into the room.

- Layout of rolls so that all joints match.

- Sizing slots with metal tape.

- Stuffing over the thermal insulation of the counter-grill.

- Installation of decorative finishes.

The distance from the foil to the finishing material is from 15 mm.

Floor insulation

In order to qualitatively insulate the floor, you will need to additionally use mineral wool, polystyrene foam and expanded polystyrene. It is allowed to work on standard surfaces or organize a substrate for underfloor heating. Experts give a step-by-step algorithm of actions to be followed:

In order to qualitatively insulate the floor, you will need to additionally use mineral wool, polystyrene foam and expanded polystyrene. It is allowed to work on standard surfaces or organize a substrate for underfloor heating. Experts give a step-by-step algorithm of actions to be followed:

- Training. The old cover is dismantled, garbage is taken out of the room.

- Inspection of the bottom structure. The peeled and cracked screed is removed, a new one is installed. All slots are closed with foam or cement-sand mortar.

- Performing a rough floor. Boards are attached to the surface with a step of up to 1 m, chipboard or plywood is fixed to the logs. Bars of 5x4 cm are attached over the materials.

- Installation of waterproofing. Previously, the surface is covered with a primer, and then lined with a waterproof film. Its edges protrude 10-15 cm beyond the walls and are fixed with a stapler. The film overlaps by 10-15 cm, all connecting lines are glued with metal tape.

- Laying Isolon. It is allowed to use material 4-10 cm thick. Before installation, the insulation is cut to the desired lengths. Laying is done on top of the waterproofing coating, the joints are glued with metal tape.

- Lag mount The extreme ones are near the walls, the intermediate ones are in increments of 50-69 cm. They are fixed with self-tapping screws.

- Installation of the second layer of thermal insulation. Auxiliary material is adapted to the size of the cells and lined without gaps. Slots are closed with foam. A polyethylene waterproofing film is placed on top of the mineral wool or polystyrene, which is fixed with brackets.

- Laying the finish.

To finish the flooring you need a substrate of sheet plywood or 3 cm thick boards.

Mounting Features

Instructions from specialists apply to any surface for insulation. When laying insulation, the following rules must be observed:

- Internal insulation provides for mounting Isolon between the finish and the wall - increases the thermal efficiency of the structure.

- The highest percentage of heat storage is provided by the material with double-sided foil.

- Two layers are laid on concrete. The first is on the cover, the second on the lags.

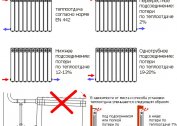

- It is better to make insulation of the loggia or balcony with a single-layer foiled Izolon according to the principle of "building cake".

- The apartment can accommodate material behind radiators - this eliminates the dismantling of walls.

- The foil layer must not come into contact with the wiring.

- To eliminate the formation of condensate, an air gap is required between the insulation and the rest of the structure.

The material is laid only joint by joint and must be glued with aluminum adhesive tape.

Thanks to the closed cells of coil insulation, 70% more heat is stored in the room. When performing thermal insulation, additional load on the structure is eliminated - a thin layer of material has high energy efficiency. It can be laid on any surface — walls, ceiling, floor, or lined on a balcony.