Gas silicate blocks are a popular building material, from which residential houses, summer cottages, sheds, garages and other low-rise household buildings are being built. The walls are durable and well protect buildings from temperature extremes. However, this is not always enough to provide a comfortable environment for living indoors. Aerated concrete insulation is the procedure that is necessary to protect the supporting structures from the destructive influence of external factors and extend their service life. This is a simple enough event for you to do it yourself. To do this, you need to make the right choice of insulation and observe the technology of its installation.

At what stage of construction is it advisable to warm the house

There is a strong opinion that the insulation of the gas block must be performed at the stage of construction of the object. We can agree with this, based on the fact that after the end of construction there are a lot of difficulties associated with the need to leave the premises or damage to landscape design. On the one hand, this is correct, but there are other aspects against such a decision.

Warming of an aerated concrete house from the outside directly in the process of removing walls has such disadvantages:

- Gas silicate is delivered to the construction site in a package that protects it from moisture. During installation, the material absorbs moisture. After isolation, it penetrates the finish, condensation occurs, fungus and mold develops.

- Aerated concrete has a strong shrinkage. If clinker brickwork is used, the difference in this indicator leads to the fact that the outer lining is cracked and disappears. This is an extremely undesirable situation, especially in the cold season.

Insulation of walls from aerated concrete from the outside should be done either in the warm season at low humidity, or preserve them and wait for such conditions to occur.

Preservation is a procedure that consists of equipping the drainage system and covering the walls with a waterproof film. The situation needs to be constantly monitored, since damage to the protection by wind, people, birds and animals is possible.

The best time for thermal insulation is the summer period, when there is sunny weather without sharp night cooling. If this is not possible, you need to wait until the walls dry out and only after that start warming the aerated concrete house outside.

The need for wall insulation from aerated concrete blocks

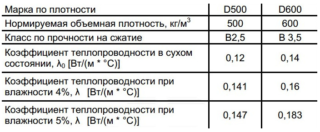

For the construction of walls, aerated concrete with a marking of D500 and above is used. Everything below is a heat insulator, not used for the construction of load-bearing structures. Building blocks have a cellular structure, which in itself contributes to good protection against temperature extremes. The logical question is the need for wall insulation from this material.

The need for thermal insulation of gas silicate walls is determined by such parameters:

- The material is highly hygroscopic. The absorbed water expands in the winter and breaks it inside. This leads to the fact that the wall loses its thickness and strength. 5-6 years and the structure will collapse.

- Even the porous structure of stones is not a guarantee against penetration of heat or cold into the room.The wall thickness cannot be infinite, in most cases it is limited to 30-40 cm, otherwise it is economically unreasonable.

- Harsh climate. To withstand extreme frosts, you need a wall thickness of gas blocks of at least 60 cm. For this, you need a foundation of appropriate width. These are high costs that far exceed needs.

- Price issue. Heaters and their installation cost significantly less than brick and foam concrete. It is cheaper to insulate the supporting structure than to increase its thickness.

Despite the advantages of aerated concrete, its thermal insulation is a technological necessity.

Recommended insulation

At construction sites, a mass of materials are offered that differ in price, reviews and operational characteristics. To make the right decision, it is necessary to carefully study the characteristics of each product and the technology of its installation. This will help to avoid mistakes and build a comfortable, durable and durable structure.

Penoplex

Penoplex is a product of an exothermic reaction and subsequent extrusion of polymer materials. The material obtained in this way is a plate of the format 100 × 100 cm and 100 × 200 cm with a thickness of 25-50 mm. The edges of the elements are made in the form of steps, which ensures reliable seamless connection in the masonry.

Extruded polystyrene foam has the following advantages:

- Vapor permeability. Achieved by creating open cells in slabs. This indicator is not inferior to supporting structures. Due to this, after warming aerated concrete with foam plastic, the building retains ventilation properties.

- The average density. Elements are characterized by sufficient strength, elasticity and resistance to mechanical stress.

- Low thermal conductivity. This quality makes it possible to make EPS plates of smaller thickness than plate, roll and sprayed analogues.

- Durability. The material does not decompose due to contact with moisture, temperature differences, salts and alkalis. The estimated service life is 100 years.

The minus of the foam is its cost, justified by the complex and expensive production technology.

Polyurethane foam

This is a modern outdoor insulation with an impressive list of advantages and benefits.

Polyurethane foam has the following characteristics:

- There is no need to pre-level the base. Foam penetrates into all cavities and fills the recesses.

- Excellent adhesion. The material adheres well to any surface, including film, oily and painted.

- High speed application to the surface. In this regard, PPU has no equal among analogues.

- Low thermal conductivity. It is comparable to the best extruded PP models.

- Vapor permeability. This property is possessed by materials with an open cellular structure.

If you decide to insulate the gas block from the outside with polyurethane foam, you should immediately consider the options for the exterior decoration of the building.

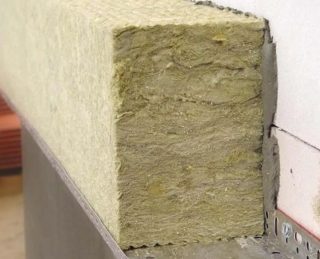

Mineral wool

Mineral wool is a traditional material used in private and industrial construction. It is produced in the form of plates and rolls, made of glass battle, steelmaking slag and natural stone. The most popular basalt wool, surpassing analogues in almost all respects.

Product Advantages:

- Ecological cleanliness. It does not contain substances harmful to people.

- Excellent vapor permeability.

- Absorbs street noise.

- Resistance to fungus, mold. Not subject to decay.

- Almost unlimited service life.

- Lightness, flexibility and resilience.

The disadvantage of mineral wool is its hygroscopicity. With the accumulation of moisture, insulating qualities are reduced.

How to insulate the walls of aerated concrete with your own hands

The choice of facade insulation technology is determined by the landscape design of the territory, its own aesthetic priorities, financial capabilities and construction skills.

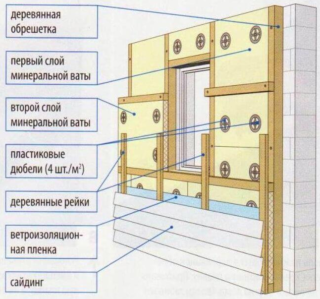

Warming under siding

The procedure is performed in the following sequence:

- Markup is in progress.

- Mounting to the wall of boards or metal profiles. The lattice parameters must correspond to the dimensions of the insulation.

- Mineral wool slabs are placed inside the frame or polyurethane foam is sprayed.

- A windproof film is attached over the crate.

The final step is facing the frame with siding. This is done in accordance with the manufacturer's instructions. For decoration, plastic or metal panels of the selected texture and color are used.

Plaster insulation

This option is used when it is decided to insulate the gas block with foam, foam or stone wool without using a hard lining.

The process is carried out in the following sequence:

- A steel profile or wooden beam is fixed on the base. This part is needed to set the initial level of work and to prevent slabs from sliding down.

- From one of the lower corners, laying of fragments begins. They are glued to the walls with cement or polymer mortar. Each subsequent upper row is made with an offset of half the plate.

- In the masonry elements, holes are drilled in the corners and in the centers. Plastic plate dowels are driven into them.

- If mineral wool is used, it is sheathed with a plastic or steel grate. Polyfoam is pasted over with a mounting grid.

- The surface is covered with plaster. Depending on the design of the site and the surrounding buildings, the surface is made smooth or corrugated.

The final stage is the application of the finishing cladding material. The wall is covered with acrylic or dispersion paint. To do this, use a brush, roller or spray.