Sauna is not only a place for taking water procedures. The presence of the steam room creates the conditions for healing and rejuvenating the body. In the common room, tea parties, friendly feasts and even business negotiations with business partners are held. All this is inseparably associated with comfort and coziness. The warm floor in the bath creates such conditions, preventing the occurrence of diseases caused by hypothermia of the legs from prolonged contact with a cold surface. Forced heating of the base is also necessary for purely operational purposes, since the building is used periodically, while being exposed to extreme environmental influences. It is advisable to insulate the bath complex at the stage of its construction, but it is also possible after its completion. To do this, you should choose the best option for heating each room in the building.

Is it possible to lay underfloor heating in the bath

There are no restrictions on the construction of a private bath with underfloor heating. Bans apply to saunas located in multi-storey buildings. The rules apply only to water heating systems.

Reasons for such restrictions:

- Cement screed and pipes filled with water create a load for which the supporting structures of the building are not designed. This is fraught with the destruction of walls, foundations, deformation of the floor slab.

- The risk of leaks in the trunk is not excluded. Under the ground floors in the houses are basements, in which warehouses are equipped, electrical panels, shut-off valves for water and heating, installation boxes for communication lines are located. Flooding can seriously damage these facilities.

Owners of private buildings are free to choose, since non-residential buildings do not fall within the scope of interests of regulatory bodies. However, financial and security considerations must be considered. Electricity and moisture are poorly compatible things, and water heating can be too expensive. The decision must be made carefully and deliberately, taking into account all the available aspects. With proper planning and properly organized construction it will not be difficult to create an effective, safe and durable system of underfloor heating.

The device of a heat-insulated floor for a steam room

Initially, such a design may seem unnecessary, since the steam room has a high temperature, and a wooden floor is laid on concrete. At first glance, the conditions are ideal in all respects, but this is not so.

Additional heating is necessary for the following reasons:

- According to the laws of physics, hot air rushes up and accumulates under the ceiling. The bottom is always cold, regardless of the temperature in the room. Standing on such a surface is unpleasant and unsafe for health. When using underfloor heating, the air layer on the floor is warm and pleasant.

- Since it is customary to steam with brooms in a traditional Russian bath, puddles form on the floor. Due to constant dampness, fungus and mold begin to develop. Contaminated wood must be changed and concrete surfaces cleaned and disinfected. Heating prevents these phenomena.

- A warm base creates additional heat, which allows you to not heat up to the limit of an electric boiler. The heat is distributed evenly, the risk of fire and burns is reduced.

Modern baths are being erected on a concrete monolithic slab.This solution contributes to the durability and strength of the structure, since wooden bases do not last long, are subject to rot and deformation. To protect against the cold coming from the earth, polystyrene, penofol or polystyrene are used. A screed of expanded clay concrete is poured over the insulation, which has low thermal conductivity. The property owner then decides which type of finish to choose.

The type of underfloor heating is selected based on the design of the stove, boiler, size and configuration of the room.

Advantages and disadvantages

In most cases, baths are separate buildings. General heating is rarely supplied to them, since it makes no sense to heat an empty object and is economically unprofitable.

Advantages of installing underfloor heating systems:

- Advance preparation of the premises. The oven only creates heat in the steam room, as its door is kept constantly closed. The use of heating of the lower level allows you to organize the heating of the object over the entire area. As a result, warm air will accumulate not only along the walls and near the ceiling, but in the entire space of the rooms.

- The ability to abandon electric radiators, the effectiveness of which is insufficient to ensure quick heating of the rooms. With sufficient power, the lower elements perform this task better and in a shorter time.

- Elimination of dampness, prevention of the development of fungus and mold. Winter lasts several months and is accompanied by large changes in temperature. The building freezes, frost and condensation form. Periodic heating of rooms helps to remove excess moisture, preventing premature destruction of wood.

- Creating comfortable conditions for vacationers. This is especially true in the cold season, when the carrier plate cools down under the influence of the cold coming from the ground. People feel good in the relaxation room, steam room and washing room.

- Easy to clean after taking procedures. Floors do not need to be wiped dry and disinfected. It is enough to remove large puddles, and the heating system will do the rest.

- Prevention of freezing water in the drain. Passing through a heated pipe, the water does not freeze to its walls, freely draining the drainage well.

This solution has its drawbacks:

- The water circuit cannot be used at low temperatures. Between the use of the sauna, the water in the pipes freezes, ruptures the pipes and destroys the screed. Continuous heating is not economically viable.

- Restrictions on the use of electrical appliances. Open contacts are not allowed in rooms with high humidity and water splashes. Communications should be regularly inspected and checked for isolation.

Despite the shortcomings, more and more property owners are inclined to equip their saunas with underfloor heating systems.

Choices

There are 2 types of designs for arranging baths - water and electric. Each of them has its own characteristics, advantages and disadvantages.

The water floor is assembled from special plastic pipes with strength, flexibility and low coefficient of thermal expansion. The line is laid in the shape of a snake or spiral. The scheme is selected based on the area of the room. Fixation is carried out between the pins fixed on the base or in ready-made foam plates with channels made in them. If the system is not connected to general heating, a pump is used to circulate the fluid, and a manifold and screw valve are used to adjust the pressure. If the circuit is closed to a separate boiler, it can be filled with antifreeze to use at any time of the year.

Electrical appliances are divided into the following categories.

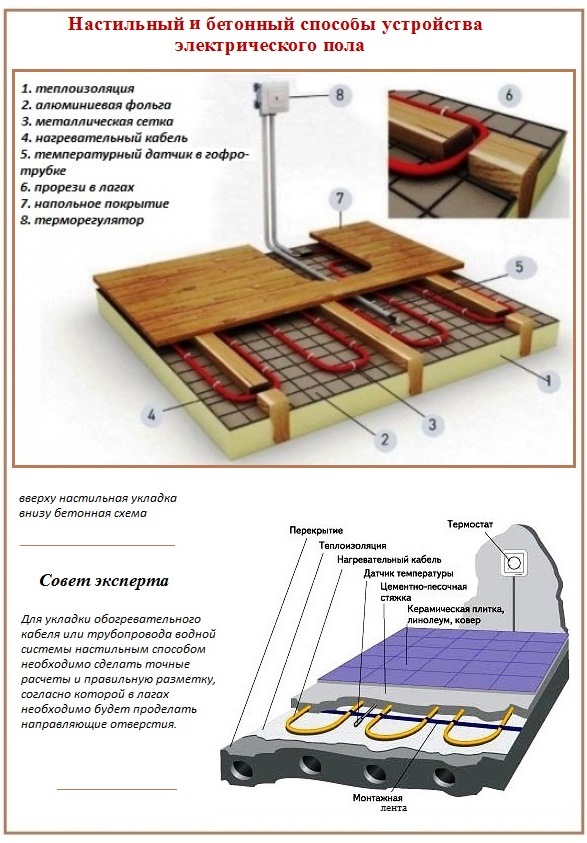

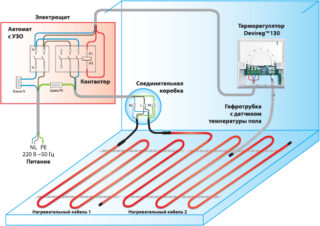

- Heating cable.It is a wire in thermally conductive plastic insulation. The thickness of the product is 6-12 mm, the radius of the maximum bend is 5-10 cm, depending on the diameter. After fixing and checking the performance, the structure is poured with cement mortar. Different models have power in the range of 10-30 W / lm. The quality of heating is determined by the distance between the turns of the snake.

- Heating mat. More effective in all respects. Thin heating elements are rigidly fixed to a plastic mesh. Mats do not need to be filled with a screed. Strips with a width of 50-100 cm can be cut to precisely fit the desired size of the room. They practice closing them with glue with a thickness of 2-3 mm when laying tiles. The mat is easy to install, even a beginner can handle this process.

- Infrared films. The principle of operation of the device is that under the influence of current, copper filaments trimmed with carbon create radiation that heats objects through which it passes. So even over a wooden flooring, the hand will feel tangible heat. The film has an affordable cost and practical device. The elements in the film are arranged in parallel, so that when one direction fails, the heating does not stop. Since the material is unstable to moisture and easily tears, it is used in dry rooms under a light screed or wooden coating.

As a rule, to make a warm floor in a bath, several types of heating devices are used.

In humid rooms, a water circuit is made or heating cables are laid. For large rooms it is better to use thin mats, since to close them you do not need to make a heavy concrete screed, which needs to be dried for 4 weeks. For a relaxation room, which is finished with a massive board, parquet or laminate, an infrared film is a good solution. It is characterized by a uniform heat distribution over each square centimeter of the surface.

Installation Instructions

The installation of each type of heating system has its own characteristics indicated in the instruction manual. A single work step for all products is the preparation of the base for laying.

Step-by-step instruction:

- Remove old trim. Clean debris, dust and debris from the base. If you have an industrial vacuum cleaner, you can use it.

- To beat off unstable fragments with a hammer, to expand narrow holes and crevices. Primer them and seal with mortar.

- Take the level and check the evenness of the plate. If there is sagging or deformation, set up the beacons, focusing on the highest angle.

- Coat the slab with a deep penetration primer. After absorbing and drying, pour the screed up to 30 mm thick. To facilitate the solution, it is better to use expanded clay as a filler. In addition to lightness, porous balls will reduce the thermal conductivity of the material.

- Place foamed penofol on the screed. The joints between the strips to seal aluminum tape.

- Arrange insulation. The roofing material is best suited for this, the edges of which are wound on the walls to a height of 20-25 cm.

After preparing the base, heating structures are installed.

The pipe is mounted on the tap using a screwed fitting. Then it is laid in accordance with the selected scheme. If the area of the room is large, you need to make several circuits to ensure normal pressure and uniform heating. After installation is complete, the return line is rigidly fixed in the collector, after which the contours are poured with heavy concrete.

It is advisable to fix the cable with a special mounting grid with fixing clamps. Thanks to this device, the cable lays down quickly with the correct adherence to the recommended interval.As with the water structure, cement mortar is poured over the cable.

Convection mats are attached to the base with brackets, glue or self-tapping screws. The edges are trimmed so that the distance to the wall is 5-10 cm, and there is no furniture above the elements. A screed is not necessary. Immediately after fixing the elements, ceramic or stone tiles can be laid on them. The advantage of this solution is that the room can be used several hours after grouting.

The easiest way to install infrared film. It must be laid on the base and glued to it with single or double sided tape. Then, on top of the fixed elements, any of the existing types of coating can be laid on glue or without it.

How to cover the underfloor heating

After pouring the screed or laying the elements on the heat-insulating substrate, the finish coating is installed.

Finishing Options:

- Ceramic or glass tiles. In the case of such a solution, a material with a non-slip ribbed surface should be selected to prevent falling.

- Wood flooring. It is advisable to use removable shields that can be brought out to dry after the end of bathing events.

- Fixed floor from logs laid on logs. In this case, waterproof varieties of wood (cedar, larch, oak) are used. Boards are treated with an antiseptic, tightly fitted, cracks are sealed with sealant.

- Reiki made of wood-polymer composite. This material is not afraid of moisture, tolerates temperature changes without consequences.

The coating should choose a beautiful, resistant to temperature extremes, strong and durable, so that every few years do not engage in tedious and expensive repairs.