The non-volatile draft regulator for solid fuel boilers is a device for coordinating the power of the unit. A mechanical device acts like a fan, has less accuracy, but does not require electricity and is cheaper. The regulator in autonomous mode changes the volume of the supplied air flow by opening the damper.

Appointment and principle of operation of the draft regulator

The mechanical device does not provide high reliability, but eliminates manual control of the boiler power and saves coal and firewood. The amount of oxygen entering the furnace affects the intensity of the flame. Combustion is controlled by closing or opening the door in the chamber.

Thermomechanical device automates process control in accordance with the algorithm:

- When solid fuel is burned, the energy carrier heats up, the liquid in the working capsule expands and acts on the working mechanism, overcoming the elasticity of the spring spiral.

- The lever relaxes the chain, the door closes and reduces the passage of air flow, which slows down combustion and smoldering begins.

- After cooling, the coolant volume decreases, the spring pulls up the actuating lever and the shutter opens slightly.

- The process is repeated cyclically until the coal or firewood is completely burned, then the spring releases the damper to the open position.

The regulator stabilizes the draft of the fresh air flow and prevents the heat exchanger from overheating. The device regulates the pressure in the heating system and makes the boiler work independent of weather conditions. The mechanical installation dries the chimney from condensate when the unit is not heated.

Draft regulator design for solid fuel boilers

The flame intensity in the boilers without any thermostat is manually changed by closing or opening the ash pan. Oxygen enters the combustion chamber due to the direct draft of the chimney pipe. A mechanical device does the job for a person, if the regulator is properly configured. At the first start-up of the installation, the chain size between the lever and the place of attachment to the damper is selected.

The flame intensity in the boilers without any thermostat is manually changed by closing or opening the ash pan. Oxygen enters the combustion chamber due to the direct draft of the chimney pipe. A mechanical device does the job for a person, if the regulator is properly configured. At the first start-up of the installation, the chain size between the lever and the place of attachment to the damper is selected.

The structure of the mechanism is different for different manufacturers, but the basic elements are present in all models:

- built-in thermostat in the form of a capsule;

- plastic head having 2 scales;

- immersion sleeve;

- stock;

- drive mechanism;

- coil spring;

- chain;

- tuning knob.

The main part is an automatic thermal element to ensure uniform temperature. The link is placed in a cylindrical box and coordinates the movement of the ash pan door by means of a chain and a lever. The body on the thread is inserted into the sleeve of the water shell, which is in contact with the energy source.

A sealed flask contains a liquid that is sensitive to temperature changes and expands greatly when exposed to heat. Using the handle on the pediment of the temperature regulator, the possibility of the lever and the damper stroke is limited, and the heating of the energy carrier is established.

Specifications

The planned operating temperature of the heating unit is included in the setting range with a two-way margin. The connecting thread on the mechanical regulator must correspond to the parameter of the turns at the place of docking with the boiler.The weight of the shutter should not exceed the lifting force of the lever, otherwise the door will not budge, in this case, the supporting part is selected with great effort.

Characteristics of the mechanism:

- the body is made of all-metal chrome-plated brass;

- the handle is made of resin with a high temperature resistance;

- the chain is made of galvanized metal;

- a highly sensitive wax thermocouple is used;

- temperature is set in the range +30 - + 100 ° С;

- connecting chain up to 1.2 m long;

- net chain strength is 0.85 - 1.2 kg;

- the lever has a length of 0.12 - 0.14 m;

- lever rotation angle 100 - 150 °;

- connects to the unit with a ¾ inch conical thread;

- maximum water temperature +120 - + 130 ° С.

The controller controls the temperature with minimal error. The draft in the chimney maintains uniformity, regardless of wind loads, the heating of the structural elements of the heating unit is stabilized.

Instrument selection recommendations

There are boilers on sale that do not have any control devices regarding traction. In them, automation is represented only by a sleeve that is installed inside the water shell. The draft regulator is a necessary device; it is purchased and installed manually. When buying a heating unit, attention is paid to the presence of such a sleeve and an ash pan door, which can open upwards.

When choosing, take into account the parameters:

- initial and boundary adjustment temperature;

- matching thread connection;

- lifting force;

- chain size;

- range of movement of the lever.

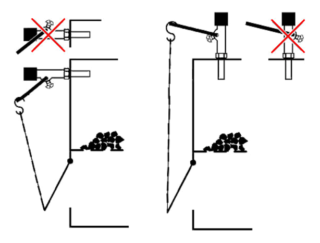

The stroke of the actuator must ensure full opening and closing of the damper. The position of the sleeve in the housing matters. If it is at the top, a draft regulator for the boiler, working vertically, is selected. When the sleeve is located on the side or in front of the body, a mechanism is bought that stabilizes the draft in the horizontal direction. There are devices that work in two directions and include 2 numerical scales in the design.

Installation and calibration of the draft regulator

Installation according to the instructions is carried out with the drained coolant in the heating system. The lever is disconnected, and the regulating mechanism is screwed into the seat by thread. For packing the threads, seals are used in the form of threads, tow, other similar materials, a fum tape is used. The direction of the tip on the drive is determined in accordance with the diagram in the technical data sheet, the lever is built in and fastened with a screw.

When horizontal, the fastener is located at the top and the heating readings are determined on a red scale. When mounted vertically, the screw is placed on the back, and the temperature is read on a yellow scale.

The setting is carried out on a running heating unit at a temperature of + 60 ° C:

- the chain is inserted into the opening of the lever body, but does not attach to the shutter, the door is placed in an open position for oxygen access;

- the fixing screw relaxes on the coordinating handle;

- the required temperature is set on the scale;

- the chain joins the shutter at the moment when the set temperature is reached.

The correct operation is checked after calibration in all modes of operation of the boiler, up to the boundary power. If necessary, the chain is shifted by 1-2 rings in one of the sides, for example, when the testimony is below the norm, the connecting element is shortened, and in the opposite case, it is weakened. The speed of change is affected by the volume and type of fuel, the inertia of the system and the unit.