The heating system includes many nodes with specific functionality. One of the main elements of the equipment is a filter that prevents contamination of equipment cavities. This device significantly increases the efficiency of the coolants, which are equipped with a large number of control valves.

Purpose and principle of operation of the mud collectors

If there is garbage, scale and rust in the heating equipment, foreign fractions accumulate at the junctions. This leads to a decrease in the diameter of the cavities and adversely affects the operation of heat exchangers, circulation pumps, as well as other structures in the equipment.

To eliminate blockages, dirt collectors are used for heating systems. They remove solid particles such as rust and scale, as well as suspended fractions that damage heating equipment.

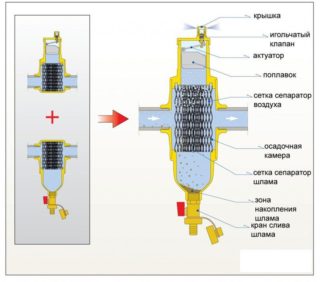

The mechanism of operation of the dirt trap is quite simple. After water gets into the nozzle, the working fluid is transported to the device body. Inside it, suspended particles fall to the bottom in the form of sediment.

The sump is installed inside the outlet pipes. After filtration, the cleaned working fluid flows back into the system. To clean the device from extraneous fractions, a glass with sediments is removed, cleaned and put back.

Varieties of filters

Classification of mud collectors for coolants is carried out according to 3 criteria:

- type of filtration of foreign fractions;

- type of service;

- installation method.

By type of particle separation

In the strainer for heating and heating of private houses, dirt is captured by the grid and remains in the accumulation zone. To clean the structure, the bottom of the glass is turned away and all technical garbage is removed.

A heating filter with a magnetic cleaning mechanism helps eliminate metal particles. They do not reduce the fluid flow rate, which is important when using powerful pumps.

By type of service

Depending on the classification by type of service, filters are divided into 3 types:

- Self-washed. The sediment from the glass and the top of the net is removed with water.

- Unwashed. When cleaning them, the coolant assembly requires complete dismantling.

- Flushing. The glass requires manual cleaning.

By type of installation

Depending on the installation, the dirt filters for the heating system are divided into 3 types.

Mud couplers with coupling type - couplings with internal thread are located on both sides of the device. Hexagons are installed on the body of the device to establish an adjustable, spanner and gas wrench.

Filters with flange connection provide for an additional o-ring with tight bolts.

Devices with a polypropylene pipe loop are used for small diameter pipes.

Advantages and disadvantages

The advantage of filters is to prevent contamination of the main components in heating equipment. The presence of a sump in the system increases the life of the coolant. In addition, among the advantages of the device are:

- fuel economy;

- reduction of reagent costs for water treatment;

- protection of convective elements of boilers.

The disadvantage of the mechanical principle of water purification is manifested in the rapid clogging of strainers with a high level of contamination of the working fluid. To solve the problem, a comprehensive filtration technique is used. It consists in the use of magnetic sludge traps to remove scale and rust, as well as a grid device to remove suspended particles.

Types of mud collectors in the heating system

Classification of filtration devices is carried out taking into account their structure and scope of use. There are 4 types of mud collectors:

- oblique brass;

- cast iron magnetic;

- flanged magnetic;

- subscriber.

Oblique brass

These filters are equipped with a coupling threaded connection with a diameter of 0.5-2 inches. These parameters are used for installation in autonomous heating systems.

The sump body is made of brass. Threaded couplings are located on both ends of the device, designed for mounting the device. There is a gasket between the body and the plug. The filter itself displays the direction of flow of the working fluid.

The device is installed in front of the circulation pump. To clean the glass, shut off the coolant supply taps and substitute the container into which the waste will flow. The mesh is cleaned with a polymer brush and washed with a stream of warm water.

Cast iron magnetic

The difference between these filters and oblique brass sumps lies in the material from which they are made. In these devices, parts are made of cast iron. Filter parts are represented by a multilayer mesh.

Flange Magnets

Instead of a screw plug, these filters have a thin flange plug with a drain hole. In this case, you can regularly drain garbage from the coolant and rinse the sump without removing the plug.

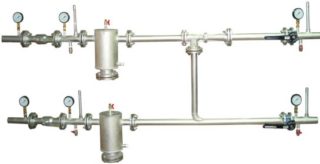

Subscriber

These sumps are used for installation in areas connecting private houses to heat mains. Such filters have high performance characteristics.

- Subscriber

- Cast iron magnetic

- Flange magnetic

Installation Rules

In all filters on the transparent panel there is an arrow of the direction of the working fluid. Installation of sumps for heating is subject to strict observance of this index. The best location options for these devices are:

- metering devices;

- circulation pumps;

- near regulatory structures of the system.

With horizontal installation, the spout of the device is located below, and with vertical installation, on the side. Otherwise, foreign fractions will not be removed from the system. It is recommended that check valves and shut-off valves are installed in front of the dirt trap, and pressure-reducing valves behind them to control pressure readings.

Mud service in the heating system

The filters for the heating boiler must be cleaned 2-3 times a year. The frequency of the procedure depends on a number of certain factors, among which the main ones are:

- equipment dimensions;

- number of nodes and control valves;

- degree of preliminary cleaning.

Often you can clean the household dirt trap yourself. To do this, close the valves, unscrew the glass, remove it and carefully clean the filter itself.

Installing a sump is one of the essential elements of heating with a large number of nodes and control valves. The filter increases the life and efficiency of the system.