Quartz vinyl tile is a durable floor covering, 70% consisting of natural components - sand and shell rock. The binder for them is polyvinyl chloride. Thanks to this ingredient, the tile becomes flexible, durable, biologically resistant and waterproof. At the same time, PVC itself is chemically neutral and does not pose a threat to humans and the environment.

The combination of warm and vinyl floors

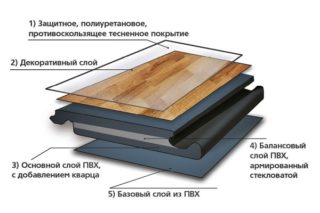

Quartz vinyl tile is a multilayer material:

- The bottom layer is vinyl. Provides adhesion of the finishing material and the base.

- Reinforcing frame consists of fiberglass pressed at high temperature.

- River sand and shell rock mixed with vinyl form a durable, moisture-resistant coating.

- The next layer is decorative. Outwardly, it imitates natural material.

- The protective face layer consists of a thin transparent polyurethane film. Its thickness determines the wear resistance of the finishing material.

How suitable is PVC tile for a warm floor, whether it is harmless when heated and does not lose its properties, worries those who choose quartz vinyl as a floor covering.

When choosing a quality material made in compliance with the technology, the floor will be safe. It can be used in residential premises, bedrooms, children's and medical facilities. The advantage of such a coating is its non-combustibility and dielectric properties.

It should be borne in mind that quartzvinyl is included in the category of expensive finishing materials, so unscrupulous manufacturers can save on raw materials. The buyer should be alerted by the low cost of the material. When used during heating, harmful substances can enter the room.

Which type is better to choose

Laying quartz vinyl tiles can be carried out in conjunction with any heated floors. But at the same time, several conditions must be observed:

- quartz vinyl must be laid on a solid foundation;

- underfloor heating should not cause heating of the finish over 40 degrees;

- the underfloor heating system is not laid under furniture without legs, since the heated air will have nowhere to go.

If the tile is laid on the adhesive mortar, the inclusion of a warm floor should be done no earlier than a day later, when the glue is completely dry. When using the dry method of mounting tiles using a lock connection, the underfloor heating system can be turned on the same day.

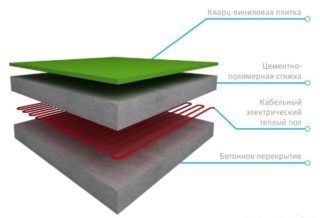

Water

Quartz vinyl tile is laid on a warm water floor mounted in a screed. This method provides an even base for the finishing material, and also protects the pipes with a coolant from mechanical influences. The disadvantage of this method is the long drying of the screed and the difficult repair of the system. Therefore, installation must be carried out immediately correctly using quality materials.

The principle of operation of the water floor is to lay out the contours according to the “snail” or “snake” scheme. Heated water circulates through the pipes and evenly gives off heat. So that all the thermal energy goes upstairs, foil material is laid on a clean and even concrete base into the room.

Electric

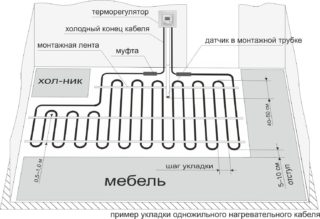

Electric underfloor heating is often laid in apartments, since it is problematic to obtain permission for water heating for them. The heat carrier is electric cables filled in with a screed. Monolithic concrete casting reliably protects cables from mechanical damage.

Stacking is performed on a previously cleaned, repaired and even base. The cables are laid out over the insulated foil material, connected to the thermostat and check the operation of the system. Only then fill in the screed.

The peculiarity of installation is that they install an electric heat-insulated floor only in open areas of the room. Where furniture is located, cables are not mounted. The minus is obvious - in such a room it is impossible to rearrange furniture without losing the effectiveness of electric heating.

Infrared underfloor heating can be mounted quickly. It comes in the form of a film. It is laid out on an even base and connected to the control unit. You can lay tiles on top. In this case, the installation is carried out on a dry, using a lock connection.

Installation of underfloor heating

When installing the underfloor heating system under the PVC floor tiles, pipes laid in the screed are used. The installation process is as follows:

- The concrete base is cleaned of debris, if necessary, perform local repairs.

- The overlap is leveled with building self-leveling mixtures.

- Insulating material is laid on the base with a foil layer up.

- A damper tape is fixed around the perimeter of the room.

- Pipes are laid according to the chosen scheme - “snail” or “snake”. To fix the contours using special plastic hooks. Also, pipes can be laid on a reinforcing mesh, to which they are attached with plastic bundles.

- The system is connected to the collector, filled with water and checked for operability.

- Pipes are poured with a screed, after disconnecting the system. You can turn it on only after the solution has completely dried.

If filling the screed is not possible, for example, on a wooden base, the pipes are laid by the dry method. In the plank flooring, channels are cut under the pipes, and after they are laid, an even plywood base is mounted under the quartz vinyl tile.

Pros and cons of underfloor heating with quartz vinyl tiles

Quartz vinyl tile is a modern finishing material, which has the following advantages:

- Layering. Each layer is made from environmentally friendly raw materials. When heating a warm floor, the finish coating does not emit harmful substances into the environment.

- Moisture resistance. Such a floor covering is universal and can be used in rooms with high humidity. This is convenient, since often an electric underfloor heating is laid in the bathroom.

- Wear resistance. If we compare the coating with the laminate, in terms of wear resistance it corresponds to 32 class.

- Practicality. The coating is easy to care for, it does not absorb dirt and is cleaned with simple detergents.

- Fire resistance. This material does not burn and does not support flame, therefore it can be used in rooms with high fire safety requirements.

- High thermal conductivity. A system with such a coating will evenly heat the room.

- Soundproof properties. The multilayer structure dampens shock waves and noise up to 19 dB.

- Maintainability. A single item is easily removed and replaced with a new one. You do not need to call the wizard for this. During operation of the electric underfloor heating, it may be necessary to replace the cable section. The final coating is disassembled for the duration of the repair and collected after its completion.

Quartz vinyl coating is characterized by a long service life of at least 25 years.This largely depends on the absence of plasticizers in the tile composition. When heated, it does not deform, so it can fit close to the protruding elements of the room and the walls.

Like any other material, quartz vinyl has the disadvantages of:

- With the adhesive mounting method, it will be difficult to dismantle the tile.

- The surface of quartz vinyl laid on a concrete base is cool and uncomfortable to the touch. Therefore, underfloor heating under such conditions will be more than appropriate.

- Gaps are formed between the tiles - this is the main difference from rolled materials.

- It is important to carefully level the base before laying the tiles. Otherwise, all its defects will be noticeable.

In tandem with a warm floor system, the structure of a quininyl tile will be justified if a room with a concrete floor is located above an unheated technical floor or subfloor. There is also a reason for additional warming of the final coating laid on the screed on cold soil.