A solid fuel boiler is a popular heater that has replaced obsolete stoves. Owners of country houses in which there is no centralized heating system use precisely such devices to heat the room. You can choose a suitable boiler, knowing the basic characteristics and properties of heating devices. You can also make a homemade device according to the diagrams and drawings.

Types of solid fuel boilers

To buy a solid-fuel heating boiler suitable for the home, you need to figure out what varieties are. The functionality of the device can be divided into two categories:

- Bypass. These are devices that can heat the room and water. Hot-water models are actively used in private homes with a permanent power grid.

- Single-circuit. They only give out heat to heat the rooms.

Also, all devices operating on solid fuel can be divided into 4 types - traditional, pellet, long burning, pyrolysis.

Classic solid fuel boilers

These are devices that look like an ordinary stove with a window for laying coal or firewood in it. The main part of the design is the heat exchanger, which transfers energy to the coolant. Cast iron and steel solid-state boilers are distinguished by material.

The positive aspects include stability, unpretentiousness, durability and low cost. In boilers there are no automation systems that often break, which saves on maintenance. It can stand without putting firewood for about 8 hours.

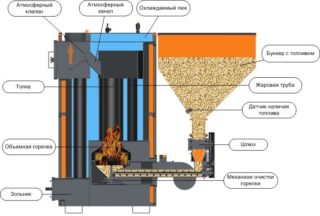

Pellet boilers

Compared to classic models, pellet ones have a special hopper and automation that supplies fuel. To fill such a boiler you need special raw materials, which are made from wood waste. They provide more heat and are cheaper than coal. Main advantages:

- High efficiency. Reaches 85%.

- Unpretentiousness. It is not necessary to constantly monitor the boiler and spend money on its maintenance.

- The duration of operation depends only on the size of the fuel hopper.

- The presence of a temperature sensor and controller. Allows you to monitor and control the temperature inside the device.

The cost of such devices is higher than that of classic boilers.

Long burning boilers

This kind of solid fuel boilers is also called top burning appliances. They are supplied with air in such a way that the fuel burns only in the upper part. Thanks to this technology, a large amount of firewood can be loaded, which will be burned out gradually, increasing the operating time.

The production of devices involved in different brands. Solid fuel boilers Zota, Buredus, Lemax and other companies of Russia, Ukraine and Europe are popular. The main production of TT furnaces are located in the Russian cities of Pskov, Moscow, Cherepovets.

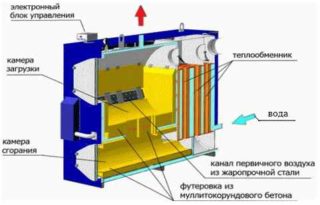

Pyrolysis (gas generating) boilers

The operation of the devices is carried out in several stages:

- Wood drying.

- Degassing. During the process, 85% of the substances are converted to a combustible gaseous state, and 15% to coal.

- Combustion. The temperature in the furnace reaches 600 ° C. Gases are oxidized, resulting in a layer of coal. Upon reaching 900 ° C, low gases are saturated with oxygen and can withstand temperatures that contribute to the decomposition of charcoal.

The design has a fan that directs the flame down. This makes it possible to control the combustion process. The efficiency of such devices is higher than that of traditional boilers.

Heat exchanger material selection

The range of boilers from various manufacturers is represented by models with a cast iron or steel heat exchanger. Each of the materials has its pros and cons, so it’s hard to say with certainty which variety is better.

Products with a cast-iron heat exchanger are a sectional design. In the event of a breakdown, any part can be easily replaced. Such options are convenient to use in private homes during transportation and in case of repair. Cast iron undergoes wet corrosion more slowly, so the heater can be cleaned less often. Thermal inertness is higher, cast-iron boilers heat up longer and cool more slowly, therefore they are considered economical. Devices are unstable to a sharp change in temperature. If cold liquid enters the hot heat exchanger, thermal shock can form, causing cracks.

The steel heat exchanger is a one-piece monoblock, which is welded in an industrial environment. There may be problems with cleaning and maintenance, since it is impossible to disassemble the boiler. The steel device is not afraid of temperature jumps due to its elasticity. Heats up quickly and cools quickly.

Fuel for boiler

Choosing a model for fuel is just as important as for material. If you have problems with the supply or storage of firewood, it makes no sense to take a wood stove, it is better to give preference to the appliance with other raw materials - for example, coal or fuel briquettes.

All types of raw materials have different indicators of power and operating time. The manufacturer of the equipment in the instructions prescribes which fuel is recommended to be used as primary and secondary and how to make the connection. Subject to these recommendations, the life of the boiler increases.

Manual and automatic loading of fuel into the boiler

The mechanism for laying raw materials is of two types - manual and automatic. Boilers with different loading methods have a different design.

Models with automatic loading consist of the main part and a special hopper in which the fuel is placed. The raw materials are subject to size requirements. For example, when working on coal, particles should be less than 25 mm. One load of fuel lasts for 3-5 days, so the user does not need to constantly feed in raw materials. This makes working with a heater simple and convenient. Sizes of bins are different, the choice depends on the preferences of the owner. Fuel is supplied either through a screw or using a piston.

Manual download is considered a more familiar way for people. The camera needs to be filled out independently. A manual loading furnace is larger than an automatic boiler, so it is not recommended to put them at home.

An automatic boiler is a more economical, stable and convenient option for use at home.

Determination of boiler power

Power is one of the main criteria for choosing heating equipment. The comfortable temperature in the room depends on it. To calculate the power yourself you need to know the following parameters:

- The area of the heated room. The higher it is, the more load will be required.

- Specific power of the heater.

- Climatic conditions of the region.

- The presence of insulation.

If the house has high-quality thermal insulation, and the ceiling height is below three meters, for heating 10 sq.m. need approximately 1.2 kW of power. About 20% of the stock for quick heating is added to this indicator. Thus, for heating an area of 100-200 sq.m. it will take up to 25 kW. More accurate calculations can be obtained using the help of a specialist. He will calculate all the additional factors that affect the characteristics, and will help determine the load.

Net volume of loading chamber

The amount of fuel that can be used at a time depends on the usable chamber volume. This characteristic shows the ratio of the volume of raw materials to power. For cast-iron models, this figure is 1.1 liters of fuel per 1.4 kW of power. For steel devices, 1.6 liters per 2.6 kW.

Top-loading boilers have a larger usable volume than other types. In addition, they are more convenient to stack raw materials.

Pyrolysis boilers are able to work for 6-10 hours from one bookmark of firewood. Efficiency reaches 90%. The size of the camera is larger than that of traditional ones, but this affects the price. The longer the battery life, the more expensive it will cost. A unit with a small camera is suitable for heating a small room.

Power consumption

Boilers are of two types according to the method of nutrition.

- Non-volatile. These are devices in which there is no need for a circulation pump, since the process occurs naturally. Non-volatile include classic units and some long-burning appliances.

- Volatile. Models containing a fan in their design. It directs air flows into the chamber. Also, automation devices operate on electricity.

Non-volatile boilers are best installed in homes where there is no stable power supply. They can act as the main and additional source of heat.

Buffer capacity

There are solid fuel home boilers for heating a private house with a heat-insulated water tank, which acts as a buffer. It is installed between the boiler and the heating system and performs the following functions:

- Protection. Keeps the heating circuit from overheating.

- Heat accumulation. It collects and stores energy from the boiler and supplies it to the system as needed.

- Communication in one chain of several types of boilers (electric, water, gas). Allows them to function within the same system.

The buffer improves temperature characteristics, increases efficiency, reduces the consumption of raw materials and the frequency of laying fuel. When choosing a buffer, the capacity is calculated taking into account that approximately 25 liters are required per 1 kW.

Self assembly boiler

You can assemble a long-burning boiler with your own hands. Drawings, videos and photo assemblies are available on the Internet. The diagram should contain the following elements:

- In the lower part there is an ashpit with a blower.

- A cast-iron grate is placed above the ash pan.

- A grill is built into the bottom of the furnace. There must be a reliable door on the camera.

- The working part of the heat exchanger is made over the furnace zone.

- Next, a chimney pipe is installed.

Before starting work, it is necessary to perform design calculations, determine the scheme and draw a drawing of the finished product. A boiler with your own hands makes it possible to create a device for your individual requirements.